Method for preparing complete orientation soft magnetic composite material

A soft magnetic composite material and orientation technology, which is applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problem that the magnetic particles cannot be flattened and completely oriented

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The specific steps are:

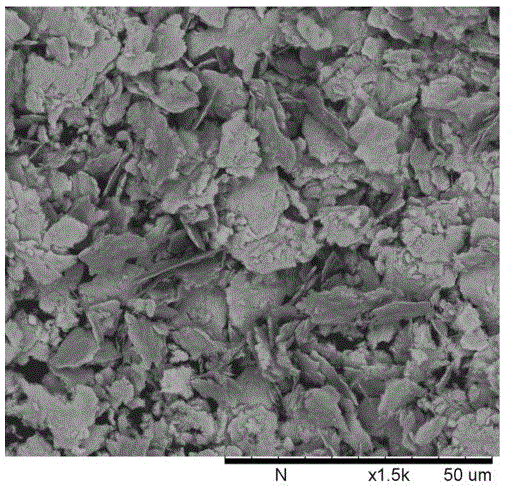

[0033] 1) Material preparation

[0034] Choose flattened iron powder with an average thickness of 0.5 μm as the raw material;

[0035] 2) mixing, pouring

[0036] Fully stir and mix 100 parts of epoxy resin and 20 parts of flattened iron powder, then add 1 part of curing agent diethylenetriamine, continue stirring for 30 seconds, and inject into the ring mold;

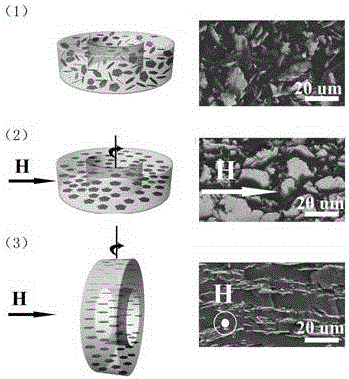

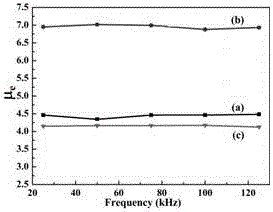

[0037] 3) Fully oriented solidification in a magnetic field

[0038] The mold after casting is quickly placed in a horizontal magnetic field for orientation. According to different orientation methods, it can be divided into three types: (1), the magnetic ring is placed horizontally, without magnetic field orientation; (2), the magnetic ring is placed horizontally, and the normal line is vertical in the direction of the magnetic field, while rotating with the normal as the axis; (3), the magnetic ring is placed vertically, the normal is parallel to the direction of the magnetic field...

Embodiment 2

[0041] The specific steps are:

[0042] 1) Material preparation

[0043] Choose flattened iron-silicon powder with an average thickness of 0.8 μm as the raw material;

[0044] 2) mixing, pouring

[0045] Fully stir and mix 100 parts of epoxy resin and 50 parts of flat iron-silicon powder, then add 2 parts of curing agent diethylenetriamine, continue stirring for 30 seconds, and inject into the ring mold;

[0046] 3) Fully oriented solidification in a magnetic field

[0047] The mold after casting is quickly placed in a horizontal magnetic field for orientation. According to different orientation methods, it can be divided into three types: (1), the magnetic ring is placed horizontally, without magnetic field orientation; (2), the magnetic ring is placed horizontally, and the normal line is vertical in the direction of the magnetic field, while rotating with the normal as the axis; (3), the magnetic ring is placed vertically, the normal is parallel to the direction of the ma...

Embodiment 3

[0050] The specific steps are:

[0051] 1) Material preparation

[0052] Choose flat sendust powder with an average thickness of 1.5 μm as the raw material;

[0053] 2) mixing, pouring

[0054] Fully stir and mix 100 parts of epoxy resin and 100 parts of flat sendust powder, then add 5 parts of curing agent diethylenetriamine, continue stirring for 30 seconds, and inject into the ring mold;

[0055] 3) Fully oriented solidification in a magnetic field

[0056]The mold after casting is quickly placed in a horizontal magnetic field for orientation. According to different orientation methods, it can be divided into three types: (1), the magnetic ring is placed horizontally, without magnetic field orientation; (2), the magnetic ring is placed horizontally, and the normal line is vertical in the direction of the magnetic field, while rotating with the normal as the axis; (3), the magnetic ring is placed vertically, the normal is parallel to the direction of the magnetic field, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com