Preparation method of highly-oriented strontium ferrite

A strontium ferrite, high-orientation technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., to achieve good dispersion and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The specific steps are:

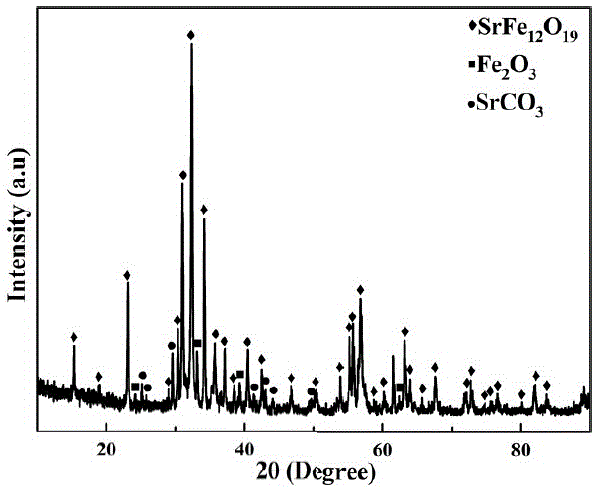

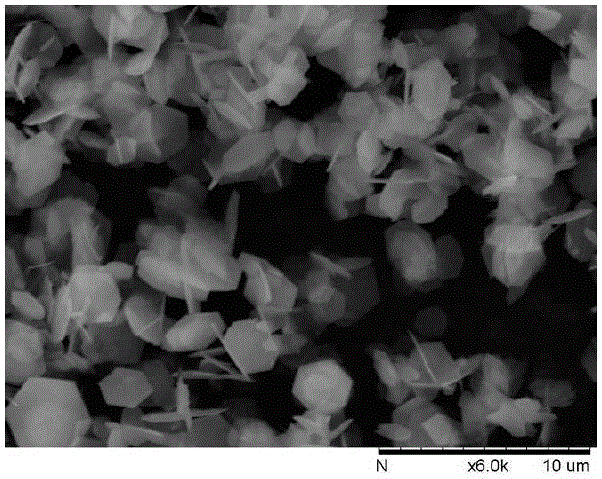

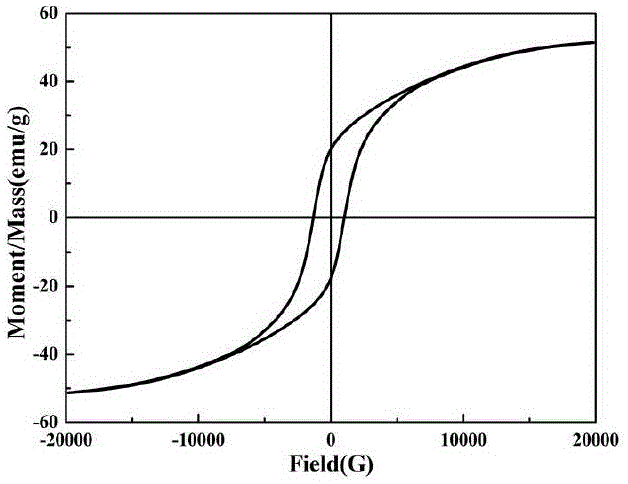

[0043] 1) Hydrothermal synthesis of strontium ferrite hexagonal sheets

[0044] with SrCl 2 ·6H 2 O, FeCl 3 ·6H 2 O and NaOH are used as raw materials, the ratio of Fe / Sr is controlled to be 3:1, the hydrothermal temperature is 160°C, and the synthesis time is 36h. After filtering, washing and drying, hexagonal flaky strontium ferrite particles are obtained;

[0045] 2) Preparation of composite system

[0046] Stir and disperse 100 parts of epoxy resin and 20 parts of strontium ferrite hexagonal sheet at 20°C for 0.5h, then add 1 part of curing agent diethylenetriamine, and continue stirring for 30s;

[0047] 3) Orientation of magnetic particles in a magnetic field

[0048] Inject the dispersion composite system into the mold, and then apply a magnetic field at the mold, the magnetic field strength is 0.01 T, and the orientation time is 60 minutes, so that the strontium ferrite hexagonal sheet is rotated to the direction of the sheet perpen...

Embodiment 2

[0053] The specific steps are:

[0054] 1) Hydrothermal synthesis of strontium ferrite hexagonal sheets

[0055] with SrCl 2 ·6H 2 O, FeCl 3 ·6H 2 O and NaOH were used as raw materials, the Fe / Sr ratio was controlled to be 6:1, the hydrothermal temperature was 180°C, and the synthesis time was 18 hours. After filtering, washing, and drying, hexagonal flaky strontium ferrite particles were obtained;

[0056] 2) Preparation of composite system

[0057] Stir and disperse 100 parts of epoxy resin and 50 parts of strontium ferrite hexagonal sheet at 40°C for 1 hour, then add 2 parts of curing agent diethylenetriamine, and continue stirring for 30 seconds;

[0058] 3) Orientation of magnetic particles in a magnetic field

[0059] Inject the dispersion composite system into the mold, and then apply a magnetic field at the mold, the magnetic field strength is 0.1 T, and the orientation time is 30 minutes, so that the strontium ferrite hexagonal sheet is rotated to the direction ...

Embodiment 3

[0064] The specific steps are:

[0065] 1) Hydrothermal synthesis of strontium ferrite hexagonal sheets

[0066] with SrCl 2 ·6H 2 O, FeCl 3 ·6H 2 O and NaOH are used as raw materials, the Fe / Sr ratio is controlled to be 8:1, the hydrothermal temperature is 200°C, and the synthesis time is 8h. After filtering, washing, and drying, hexagonal flaky strontium ferrite particles are obtained;

[0067] 2) Preparation of composite system

[0068] Stir and disperse 100 parts of epoxy resin and 100 parts of strontium ferrite hexagonal sheet at 60°C for 2 hours, then add 5 parts of curing agent diethylenetriamine, and continue stirring for 30 seconds;

[0069] 3) Orientation of magnetic particles in a magnetic field

[0070] Inject the dispersion composite system into the mold, and then apply a magnetic field at the mold, the magnetic field strength is 0.3 T, and the orientation time is 10 minutes, so that the strontium ferrite hexagonal sheet is rotated to the direction of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com