OLED display module and making method thereof

A technology for a display module and a manufacturing method, which is applied in the fields of semiconductor/solid-state device manufacturing, electrical components, and electrical solid-state devices, etc., can solve the problem that the driving chip 200 and the flexible circuit board 300 occupy a large space and a large area, and affect the appearance of the module. and other problems, to achieve the effect of increasing the effective display area, reducing the lower boundary area, and making the effective display area larger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

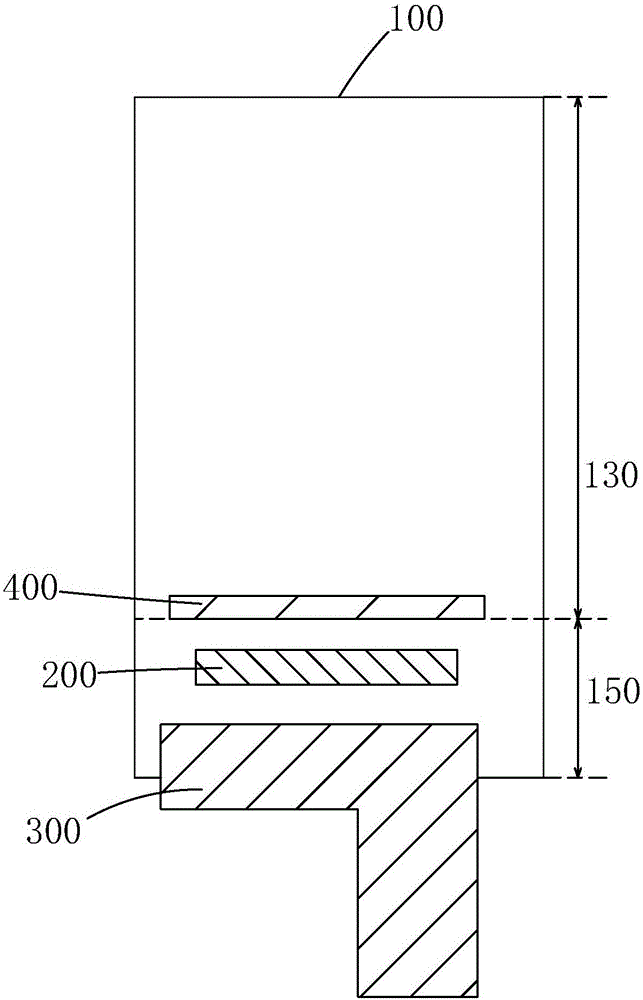

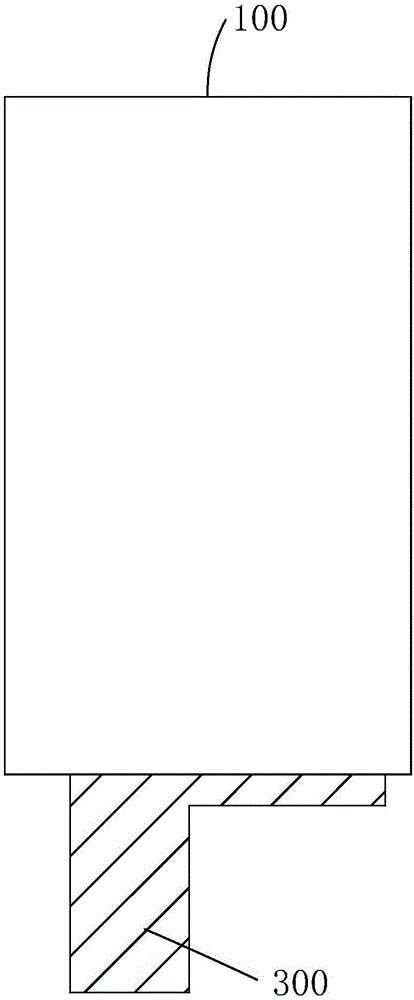

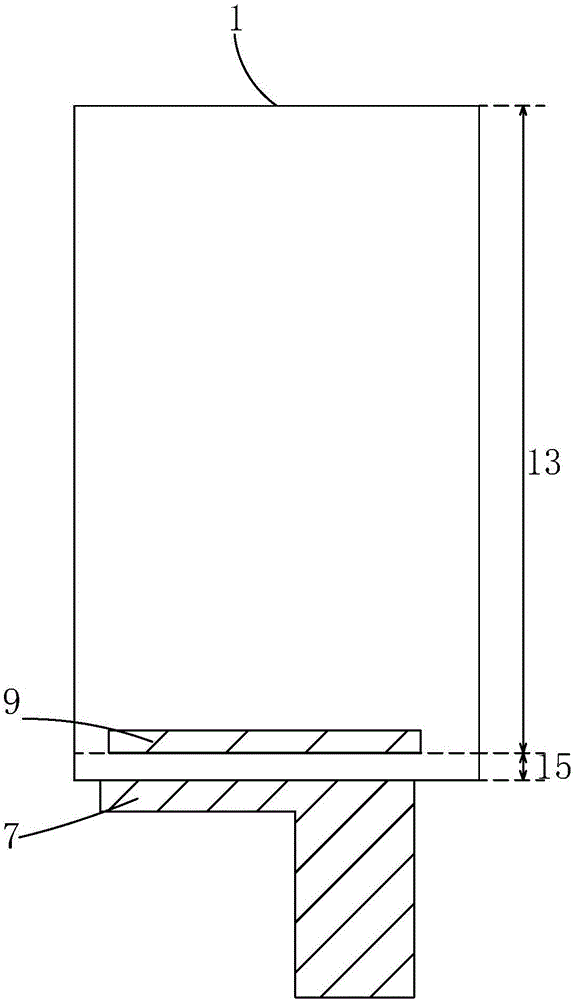

[0031] see image 3 and Figure 4 , the present invention first provides an OLED display module, comprising an OLED display 1, a conductive coating 3 coated on a partial area of the back of the OLED display 1, fixed on the conductive coating 3 and electrically connected to the conductive coating 3 The driver chip 5, the flexible circuit board 7 arranged on the back of the OLED display 1 and electrically connected to the conductive coating 3, and the source input arranged on the bottom of the front of the OLED display 1 and electrically connected to the conductive coating 3 End 9. On the front of the OLED display screen 1 , above the source input terminal 9 is an effective display area 13 , and below the source input terminal 9 is a lower b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com