A material bidirectional stretching device

A bidirectional stretching and transverse stretching technology, applied in the field of stretching, can solve the problems of stretching uniformity, low stretching efficiency, and high cost, and achieve easy realization and operation, improved production efficiency, and stable equipment operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

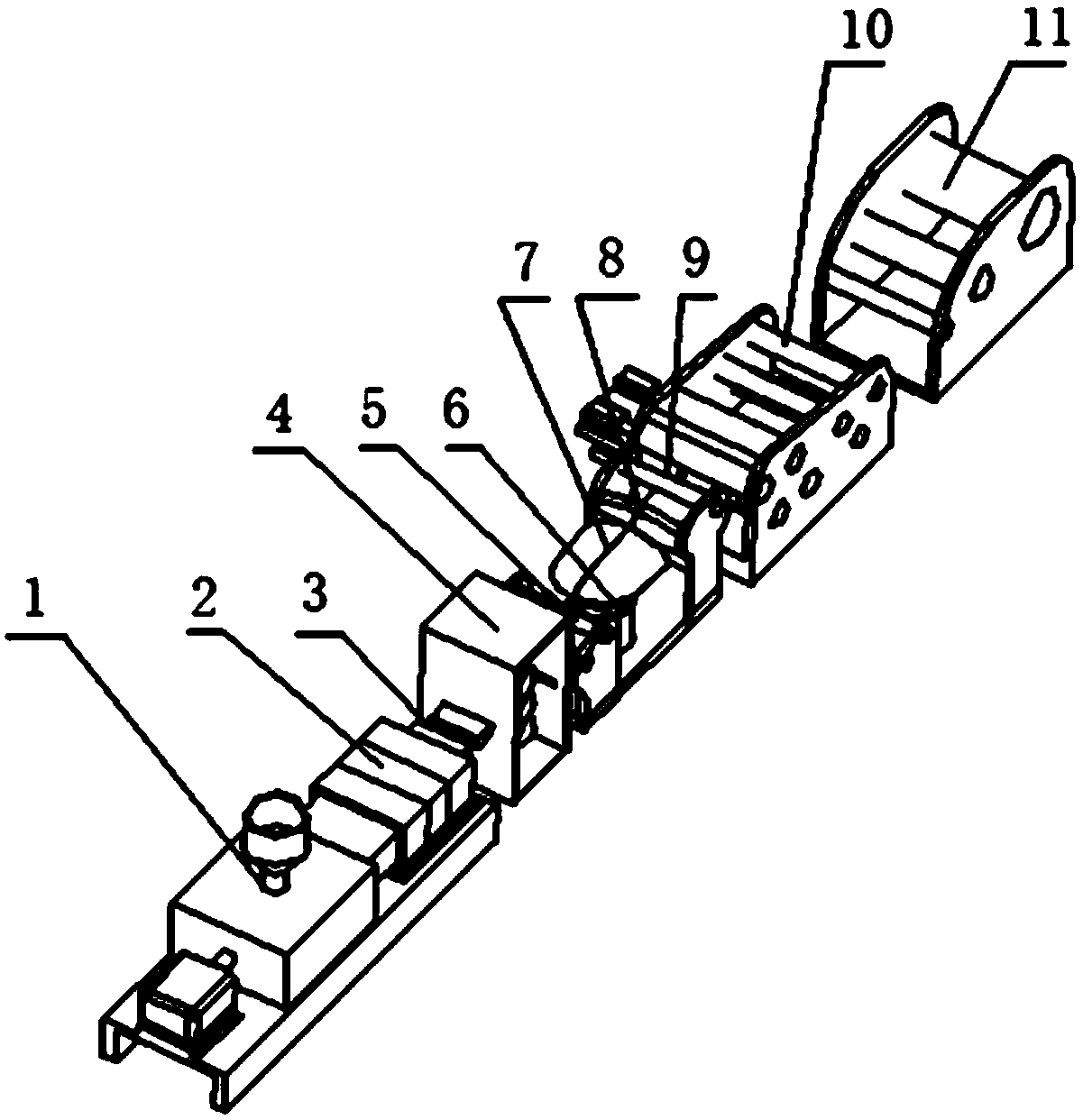

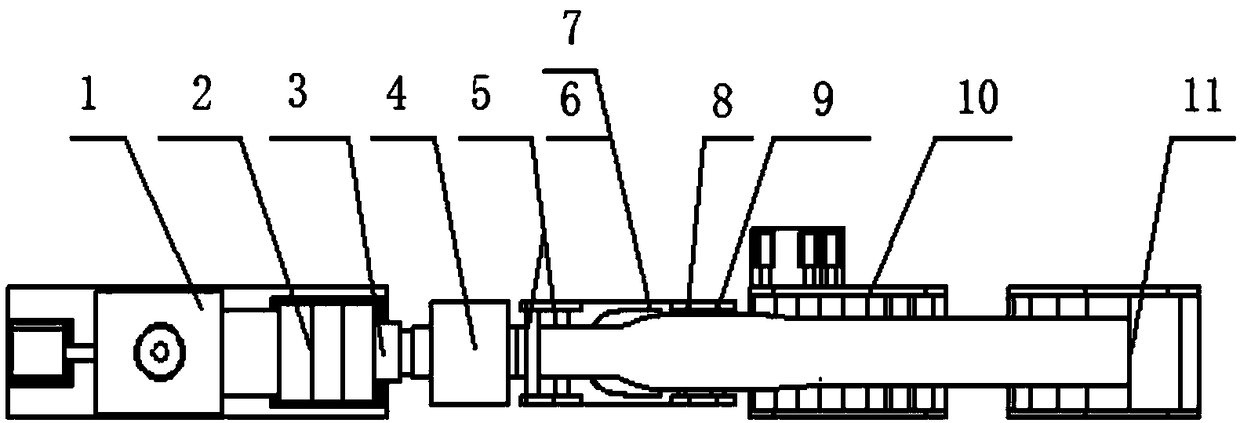

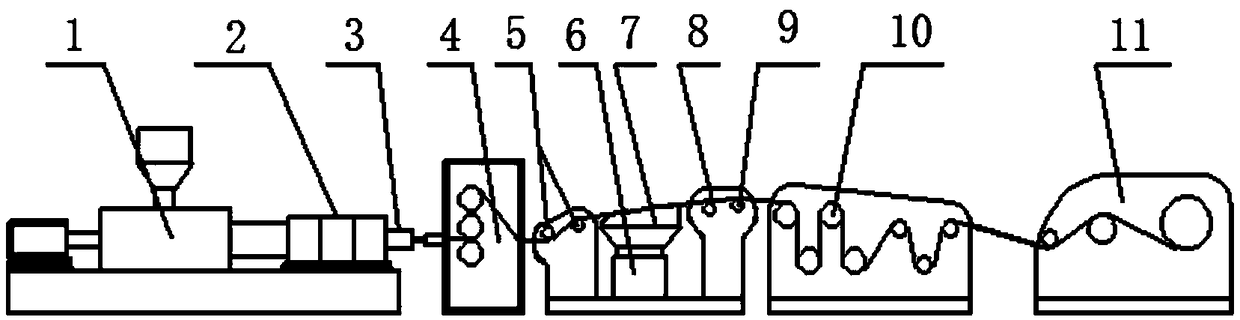

[0029] A material bidirectional stretching device of the present invention, such as figure 1 As shown, it includes plasticizing equipment 1, transition equipment 2, die 3, calender 4, transverse stretching device, longitudinal stretching device 10 and traction and winding device 11, which are sequentially connected in series to form a plastic sheet. A system for biaxially stretching materials and films. The transverse stretching device includes a tensioning wheel A5, a lifter 6, a streamlined boss 7, a flattening roller 8 and a tensioning wheel B9.

[0030] A material bidirectional stretching device of the present invention, such as figure 2 , 3 As shown, the plastic is obtained by extruding from the plasticizing device 1 through the transition device 2, the die 3 and the calender 4. The transitional device 2 can be a laminator, which is used to improve the comprehensive mechanical properties of the material and facilitate the subsequent stretching process. The die 3 deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com