Automatic clamping cup tray with sensing devices

A technology of sensing device and cup holder, which is applied in transportation and packaging, special positions of vehicles, vehicle parts, etc., can solve problems such as falling under the brake, clutch or accelerator, no fixing device for the cup holder, and the water cup jumping out of the cup hole, etc. To achieve the effect of wide range of use, simple and beautiful structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

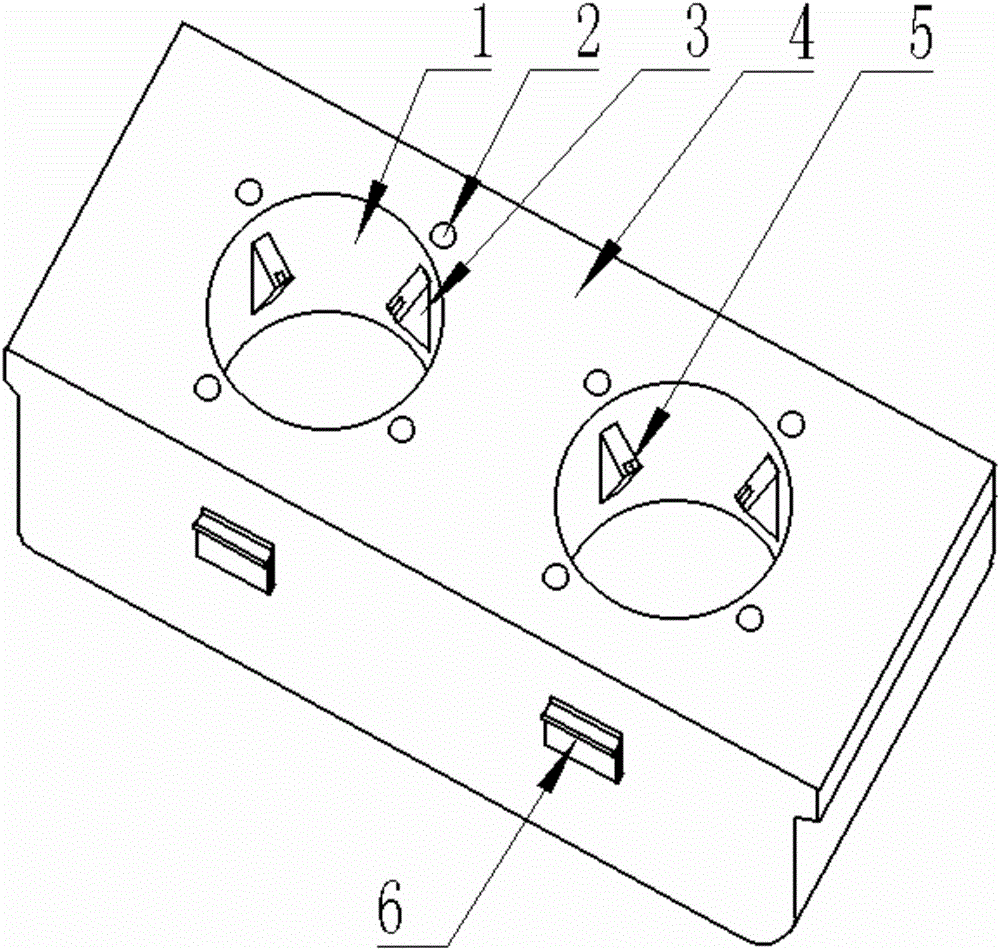

[0021] An automatic clamping cup holder with a sensing device, mainly composed of a cup hole 1, a sensing device 2, a movable cup card 3, a cup holder body 4, a pressure sensing device 5 and an installation buckle 6; the cup holder body 4. A cup hole 1 is arranged on the mirror image downwards on the upper surface, which can make the upper surface of the cup holder body 4 relatively flat, making the whole more concise and comfortable; the upper surface of the cup holder body 4 is evenly arranged along the circumference of the cup hole 1 There are 4 small holes, and the induction device 2 is installed in the small hole. The distance between the induction device 2 and the cup hole 1 is 6mm-8mm. , also under the premise of ensuring that the upper surface of the cup bracket body 4 is relatively flat, the induction device 2 is arranged, and the vertical upward setting can prevent the induction device 2 from being disturbed by the water cup; the middle part of the inner wall of the c...

Embodiment 2

[0024] This embodiment is further improved on the basis of Embodiment 1. The number of the movable cup cards 3 is 3-5 and they are jointly connected with a synchronization device. The radial height of the movable cup cards 3 along the cup hole 1 is 13mm, and the movable The contact between the cup card 3 and the water cup is set in an arc shape. 3-5 movable cup cards 3 can meet the demand for stable clamping, the movable cup card 3 is equipped with a synchronization device to make the force of each movable cup card even and keep the water cup in the center of the cup hole, the radial height and cup The variable aperture formed by the cooperation of the diameter of the hole 1 can meet the clamping requirements of most water cups on the market. The arc setting can make the contact surface between the movable cup card 1 and the water cup larger, so that the clamping is more stable.

[0025] The number of the cup holes 1 is 2, the distance between the cup holes 1 and the front and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com