Material lead device for brush wheels of pressing machine

A brush wheel and press technology, applied in the directions of transportation, packaging, roller table, etc., can solve the problem of debris affecting production, and achieve the effect of reducing the generation of debris, ensuring production safety, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

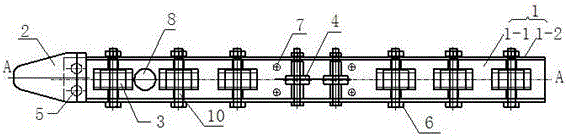

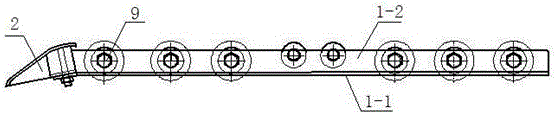

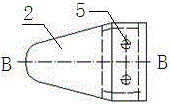

[0024] The brush wheel guide device of the press in this embodiment includes a guide groove 1, a guide head 2, a brush wheel 3, and a roller 4, wherein the guide groove 1 includes a base plate 1-1, and side plates 1 on substantially both sides -2, the base plate 1-1 and the side plates 1-2 on both sides form a groove shape, the guide head 2 is fixedly connected with one end of the base plate 1-1, and the brush wheel 3 and the roller wheel 4 are respectively located on the base plate 1 of the guide groove 1 Above -1, the two ends are connected to the side plates 1-2 on both sides respectively, and a height difference is formed between the upper surface of the brush wheel 3 and the upper surface of the roller wheel 4. In this embodiment, the brush wheel 3 is made of plastic material , Roller 4 is made of steel.

[0025] The guide head 2 is a wedge-shaped stainless steel guide head 2. One end of the guide head 2 is narrow and the other end is wide. One end of the base is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com