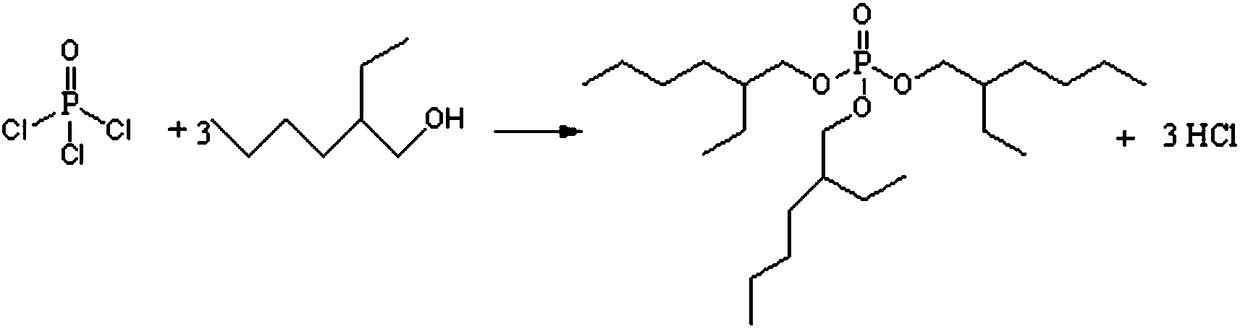

A kind of preparation method of triisooctyl phosphate

A technology of triisooctyl phosphate and isooctyl alcohol, which is applied in the field of preparation of triisooctyl phosphate, can solve the problems of high by-products and low yield, and achieve the goals of reducing pollution, increasing reaction yield, and saving production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

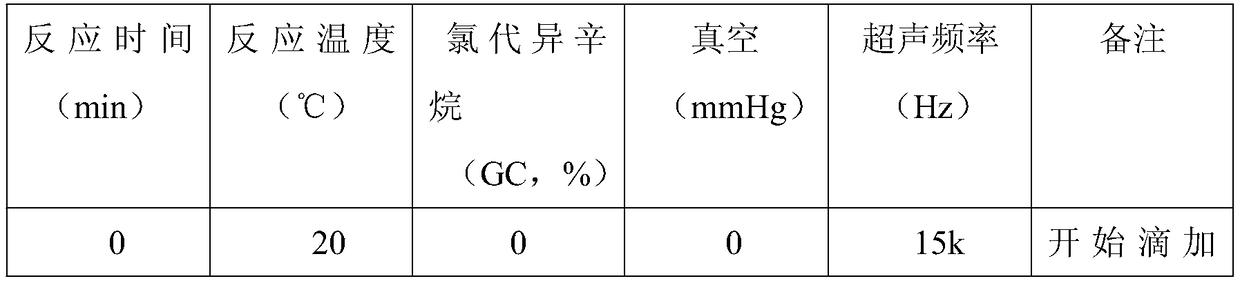

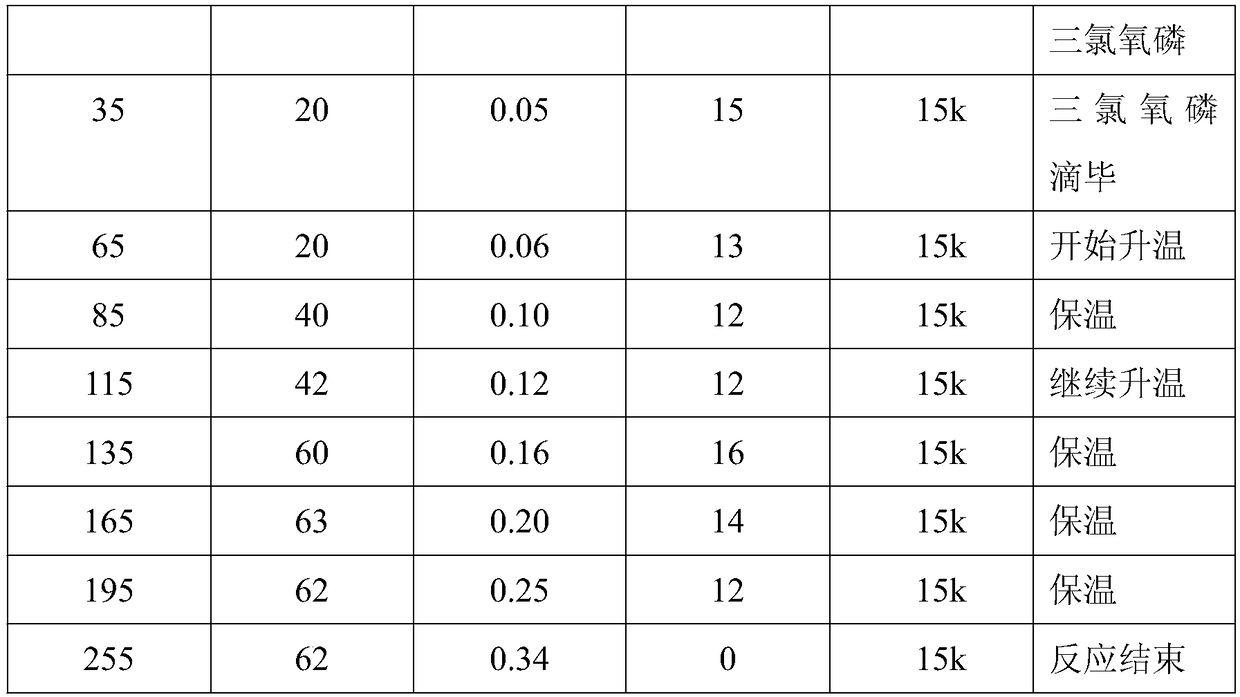

Embodiment 1

[0017] A 250 mL four necked round bottom flask equipped with a mechanical stirrer, constant pressure funnel, thermometer, condenser, and vacuum connection with control valve was placed in the ultrasonic apparatus. Nitrogen purging, isooctyl alcohol (148.2g, 1.14mol) is dropped in the flask, stirs, magnesium chloride (0.25g, 0.005g / g phosphorus oxychloride), then drops into phosphorus oxychloride (50g, 0.3257mol) to constant Press the funnel, pull vacuum, turn on the ultrasonic instrument, cool to 20°C, start to slowly add phosphorus oxychloride dropwise, the system exothermic obviously. After dropping, keep the temperature for 1 hour, slowly raise the temperature to 40°C, keep the temperature for 1 hour, and finally raise the temperature to 60°C, and keep the temperature until the end of the reaction. According to gas chromatography analysis, the content of chloroisooctane is 0.3483%. The control conditions in the reaction are shown in Table 1-1, and the gas chromatography an...

Embodiment 2

[0026] A 250 mL four necked round bottom flask equipped with a mechanical stirrer, constant pressure funnel, thermometer, condenser, and vacuum connection with control valve was placed in the ultrasonic apparatus. Nitrogen purging, phosphorus oxychloride (50g, 0.3257mol) was dropped into the constant pressure funnel, then isooctyl alcohol (156.7g, 1.2052mol), magnesium chloride (0.25g, 0.005g / g phosphorus oxychloride) was dropped into the flask Inside, stirring, vacuuming, turning on the ultrasonic instrument, cooling to 10°C, and slowly adding phosphorus oxychloride dropwise, the system exothermic obviously. After dropping, keep the temperature for 1 hour, slowly raise the temperature to 40°C, keep the temperature for 1 hour, and finally raise the temperature to 60°C, and keep the temperature until the end of the reaction. According to gas chromatography analysis, the content of chloroisooctane is 0.3494%. The control conditions of the reaction are shown in Table 2-1, and th...

Embodiment 3

[0033] A 250 mL four necked round bottom flask equipped with a mechanical stirrer, constant pressure funnel, thermometer, condenser, and vacuum connection with control valve was placed in the ultrasonic apparatus. Nitrogen purging, phosphorus oxychloride (50g, 0.3257mol) was dropped into the constant pressure funnel, then isooctyl alcohol (169.4g, 1.3029mol), magnesium chloride (0.25g, 0.005g / g phosphorus oxychloride) was dropped into In the flask, stir, pull vacuum, turn on the ultrasonic instrument, cool to 10°C, start to slowly add phosphorus oxychloride dropwise, and the system exotherms obviously. After dropping, keep the temperature for 1 hour, slowly raise the temperature to 40°C, keep the temperature for 1 hour, and finally raise the temperature to 60°C, and keep the temperature until the end of the reaction. According to gas chromatography analysis, the content of chlorinated isooctane is 0.3496%. The control conditions in the reaction are shown in Table 3-1. The gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com