A rubber desulfurization method and device

A desulfurization device and rubber technology, applied in the field of rubber desulfurization, can solve problems such as incomplete desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

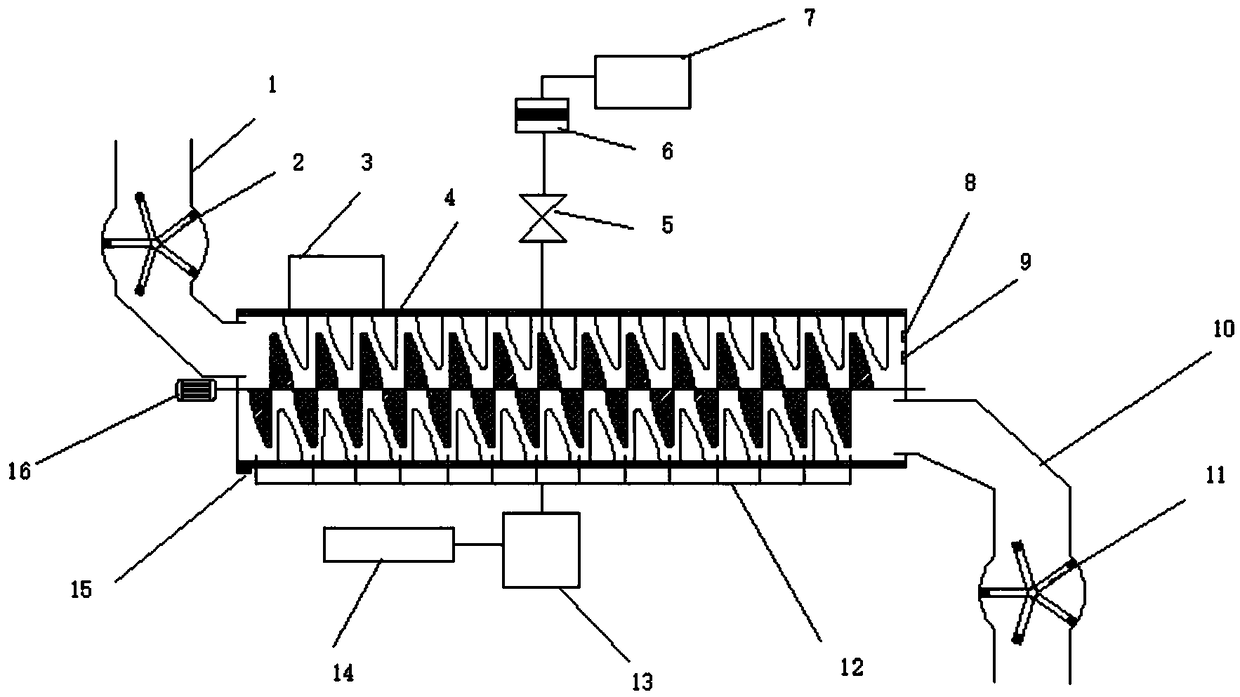

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

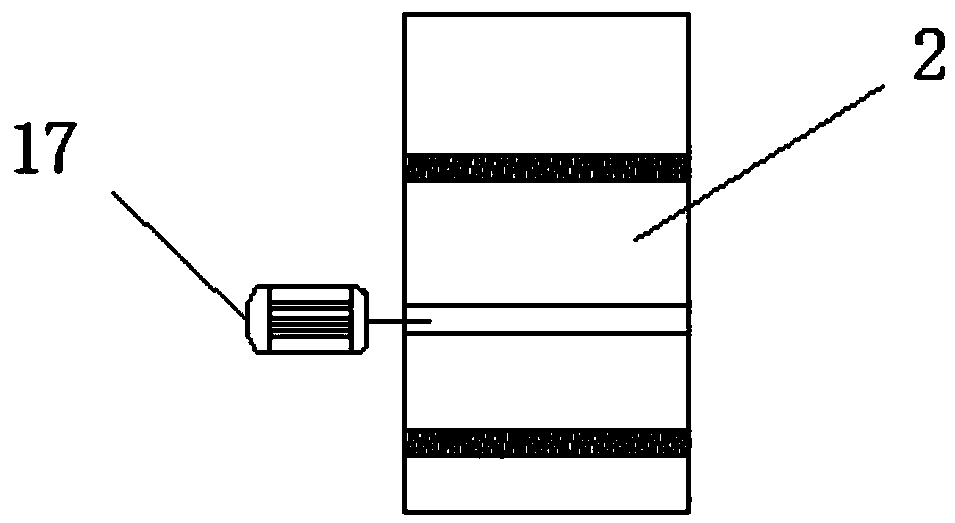

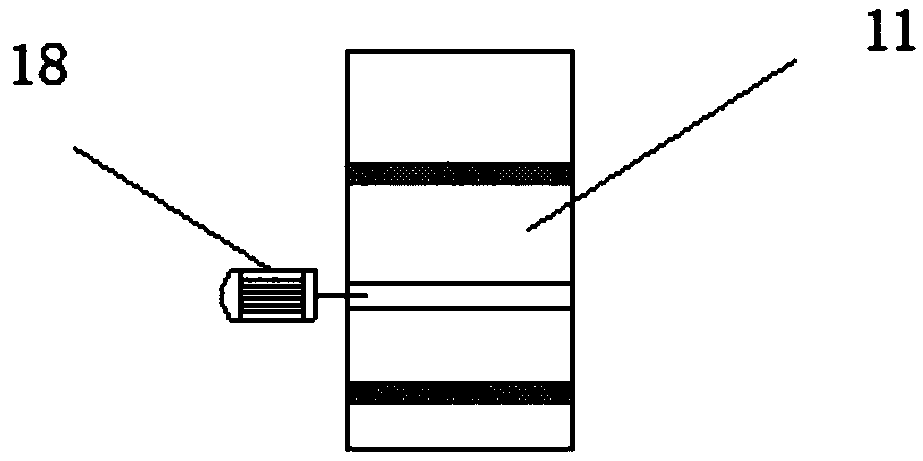

[0025] The first embodiment of the present invention discloses a rubber desulfurization method and device. Before desulfurization, the rubber is pulverized; in the pulverization process, the rubber material is put into an internal mixer for pulverization, and the pulverized rubber particles have a size of Between 1mm and 30mm, the temperature required for crushing is controlled at 160-170°C, and the pressure is set at 18-25MPa; the microwave desulfurization process is divided into the first stage of microwave desulfurization and the second stage of microwave desulfurization; the first stage is carried out first Microwave desulfurization, the microwave desulfurization steps are: firstly carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com