Aluminum electrolysis flue gas wet desulphurization wastewater treatment system

A waste water treatment system and wet desulfurization technology, applied in the field of defluorination and electrolytic aluminum flue gas desulfurization, can solve the problems of reducing the removal efficiency of the absorption tower, affecting the quality of the slurry, and being unable to desulfurize, reducing the content of suspended solids, Prevent quality deterioration and ensure desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

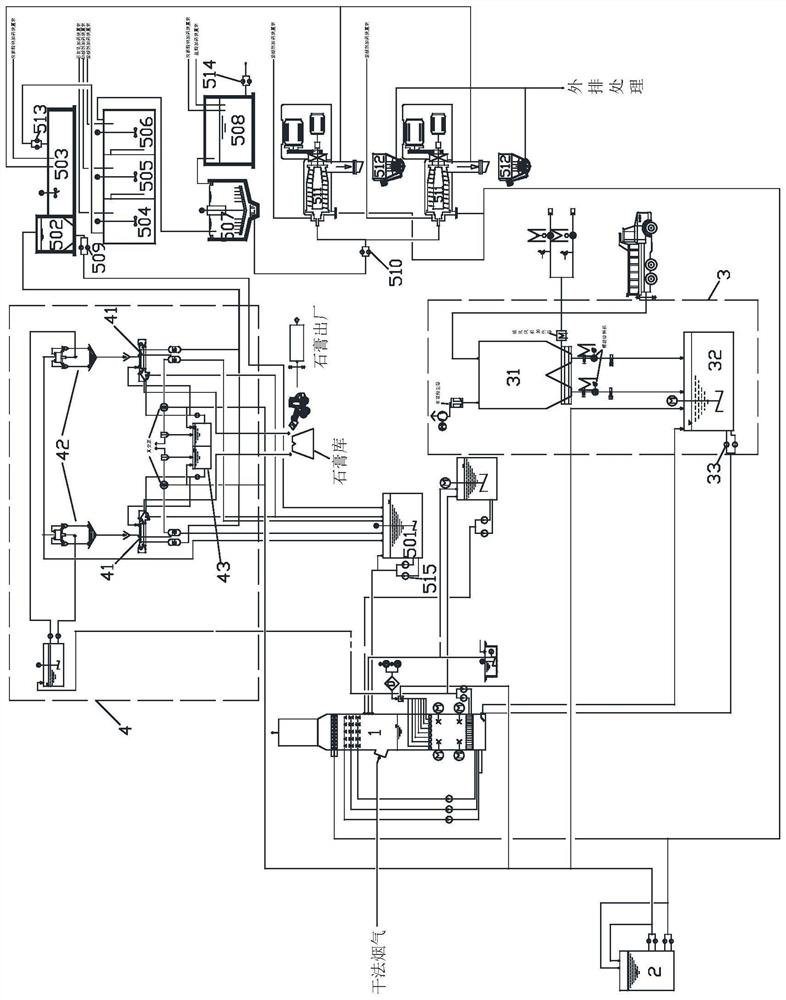

[0009] Embodiment 1: as figure 1 As shown, the aluminum electrolysis flue gas wet desulfurization system includes an absorption tower 1, a process water tank 2, an absorbent preparation system 3, a dehydration system 4, and an aluminum electrolysis flue gas wet desulfurization wastewater treatment system 5; wherein, the process water tank 2 is an absorption tower The spraying system of 1 sprays, the absorbent preparation system 3 prepares the absorbent, the filter cloth flushing water tank 43 of the dehydration system 4 and the flushing port of the centrifuge 511 of the wastewater treatment system 5 provide process water.

[0010] Absorbent preparation system 3 uses limestone powder to make slurry, including limestone powder bin 31, limestone slurry pool 32, limestone slurry pump 33 and related pipeline valves. The reducing agent from the limestone powder tank truck is stored in the limestone powder bin 31, and the limestone powder is quantitatively added to the limestone slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com