A method for smelting coarse-grained steel

A technology for coarse-grained steel and molten steel, which is applied in the improvement of process efficiency, furnace type, furnace, etc., and can solve the problem of not meeting the grain size requirements of coarse-grained steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

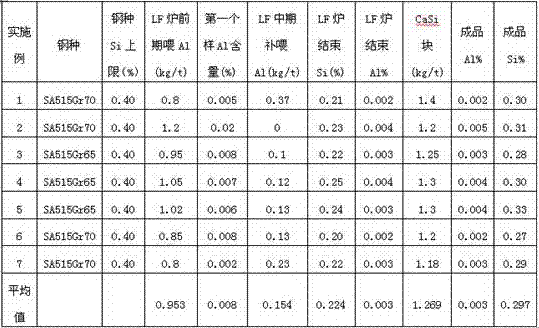

[0020] Examples 1-7: See Table 1 for the specific process of the method for smelting coarse-grained steel and the Al and Si contents of the product (finished product).

[0021] Table 1: Process parameters and Al, Si content of the embodiment

[0022]

[0023] A steel company produced 80 furnaces of coarse-grained steel with the requirement of Al≤0.005wt% by using the above-mentioned method for smelting coarse-grained steel. The steel types include SA515Gr65 and SA515Gr70, and the Al content of all finished steels is between 0.002% and 0.005%. , The passing rate of flaw detection of the rolled steel plate is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com