Boiler feed water deaeration method

A boiler feed water and deaeration tower technology, applied in separation methods, feed water heaters, chemical instruments and methods, etc., can solve the problems of insufficient steam utilization and poor deoxidation effect, so as to reduce energy consumption, save costs, improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will now be further described in conjunction with the drawings and embodiments, but the present invention is not limited to the following implementation situations.

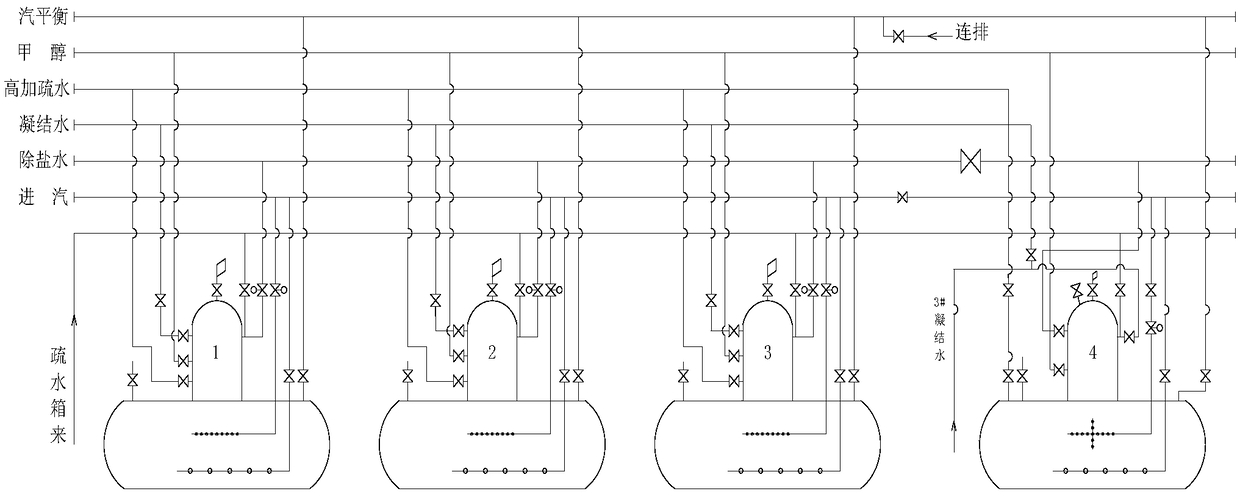

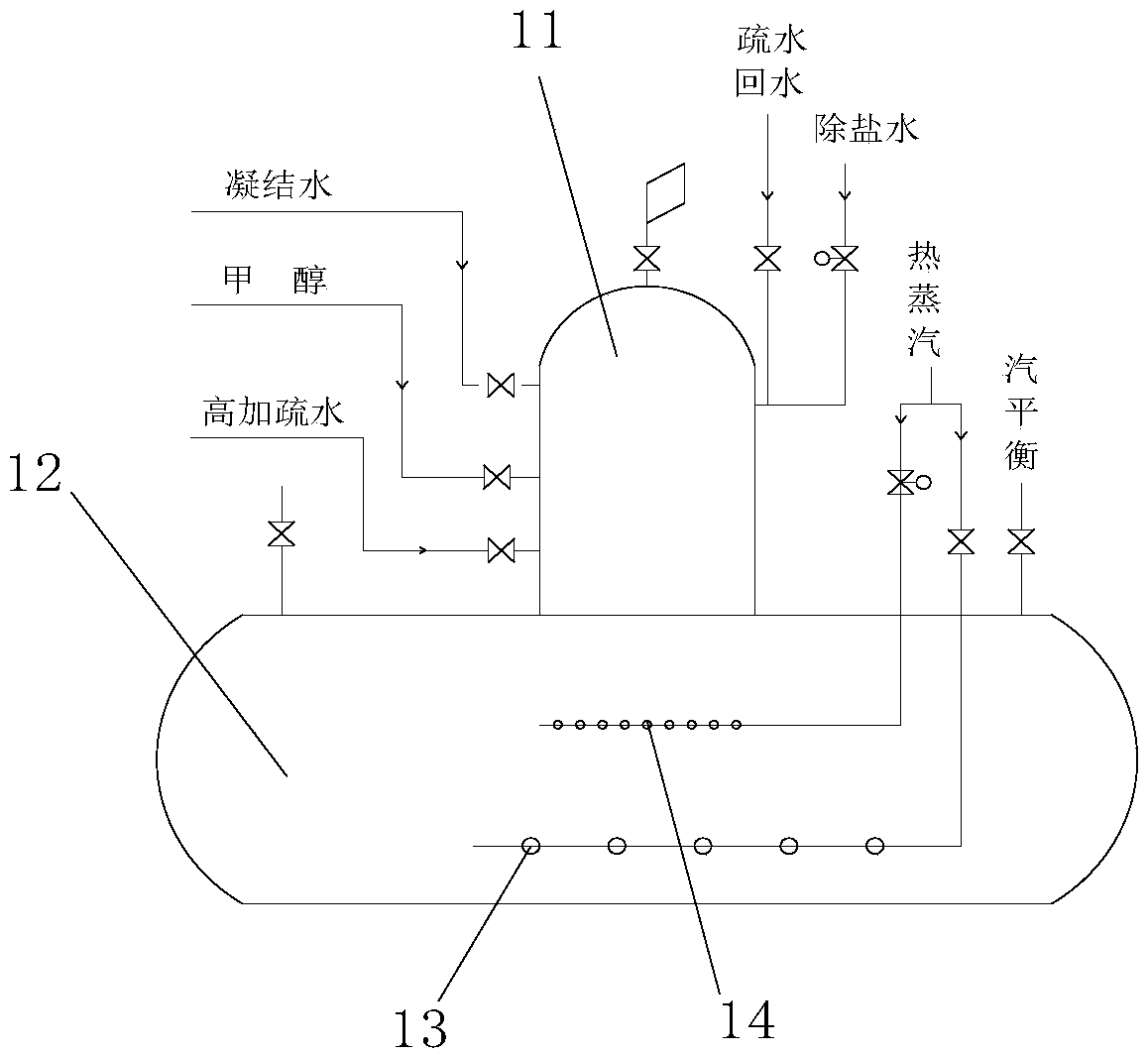

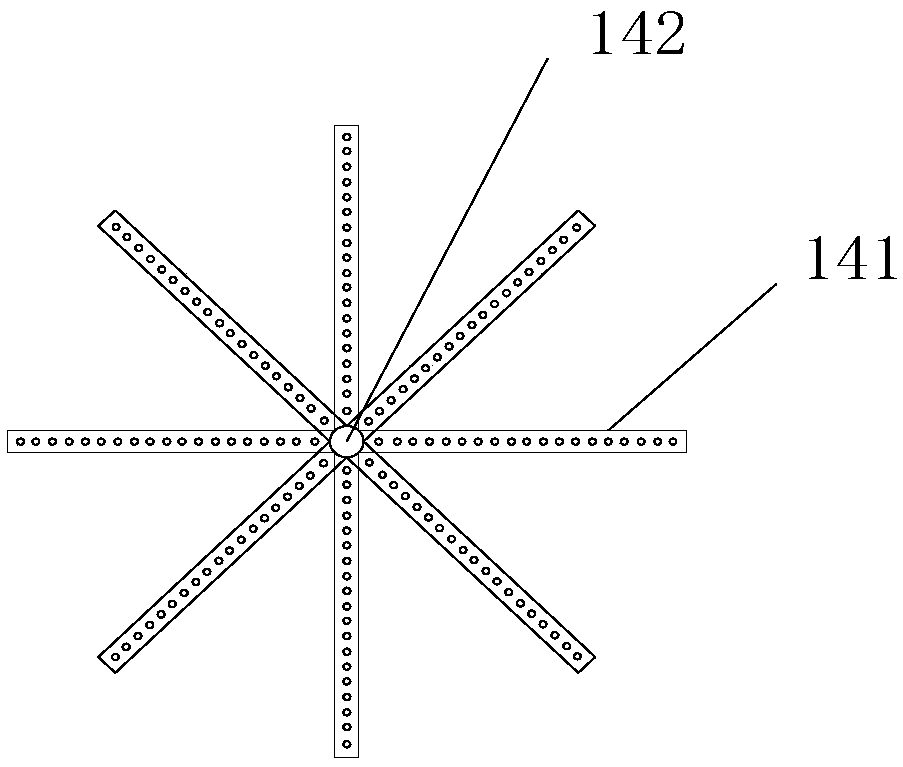

[0020] The boiler feed water deaeration treatment system of the present invention includes a medium-sized deaerator 1, a large-scale deaerator 4 and peripheral pipelines. The peripheral pipelines include methanol treatment water pipelines, high-pressure drainage pipelines, condensate water pipelines, desalinated water pipelines and steam pipelines. The medium-sized deaerator 1 can be one or more, and it can be increased or decreased according to the amount of treated water, such as figure 1 As shown, in this embodiment, there are 3 medium-sized deaerators 1 connected in parallel, and 3 medium-sized deaerators 1 and 1 large-scale deaerator 4 are connected in parallel, wherein the methanol treatment water pipeline, the high-pressure drain pipeline, and the conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com