Low-splashing type safe welding rod

A welding rod and safety technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of welding operators' health injury, unavoidable welding slag spatter, fire and other problems, so as to improve quality and stability resistance, large-scale splash prevention, oxidation or corrosion prevention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

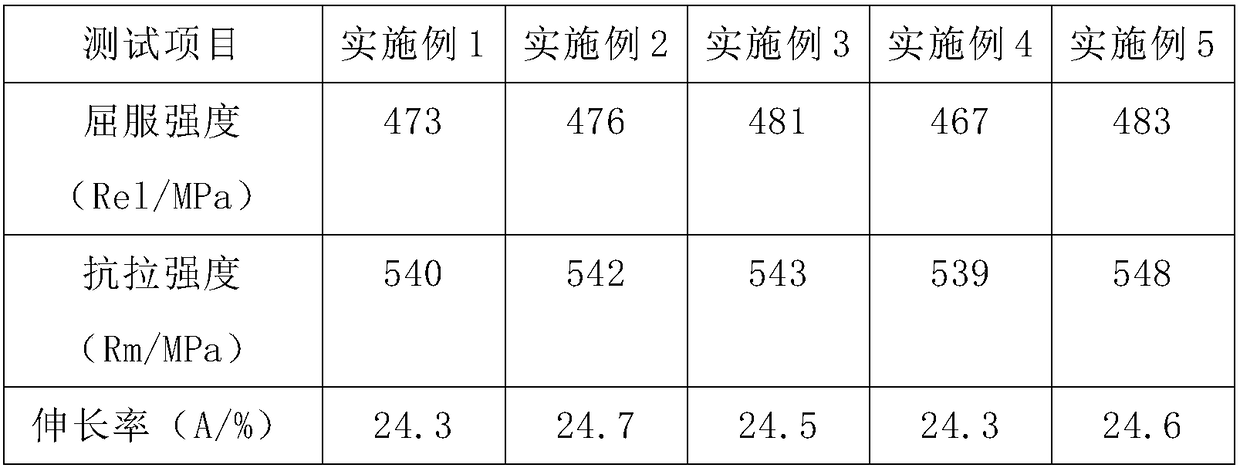

Examples

Embodiment 1

[0023] A low spatter type safety welding rod, the welding rod is composed of a welding core and a first welding flux layer and a second welding flux layer wrapped on the welding core in sequence.

[0024] In terms of parts by mass, the composition of the first flux layer includes: 30 parts of high-carbon ferrochrome, 5 parts of medium-carbon ferromanganese, 15 parts of tungsten carbide, 8 parts of nickel powder, 2 parts of rutile, 1 part of ferrosilicon, and 4 parts of ferrovanadium. , 1 part of magnesium oxide, 2 parts of fluorite, 0.4 part of fluoride, and 20 parts of adhesive.

[0025] The ingredients of the second welding flux include: 60 parts of rosin, 8 parts of vaseline, 2 parts of hydrogenated abietyl alcohol, 4 parts of succinic acid, 1 part of diethanolamine, and 1 part of surfactant.

[0026] The thickness of the first flux layer in the electrode is 7 times of the thickness of the second flux layer; the fluoride in the first flux layer is calcium fluoride; the adhe...

Embodiment 2

[0029] A low spatter type safety welding rod, the welding rod is composed of a welding core and a first welding flux layer and a second welding flux layer wrapped on the welding core in sequence.

[0030] According to the parts by mass, the composition of the first flux layer includes: 40 parts of high-carbon ferrochrome, 10 parts of medium-carbon ferromanganese, 20 parts of tungsten carbide, 10 parts of nickel powder, 3 parts of rutile, 4 parts of ferrosilicon, and 6 parts of ferrosilicon. , 3 parts of magnesium oxide, 3 parts of fluorite, 0.8 parts of fluoride, and 25 parts of adhesive.

[0031] The ingredients of the second welding flux include: 70 parts of rosin, 15 parts of vaseline, 5 parts of hydrogenated abietyl alcohol, 7 parts of succinic acid, 2 parts of diethanolamine, and 3 parts of surfactant.

[0032] The thickness of the first flux layer in the electrode is 10 times the thickness of the second flux layer; the fluoride in the first flux layer is sodium fluoride;...

Embodiment 3

[0035] A low spatter type safety welding rod, the welding rod is composed of a welding core and a first welding flux layer and a second welding flux layer wrapped on the welding core in sequence.

[0036] In terms of parts by mass, the composition of the first flux layer includes: 35 parts of high-carbon ferrochrome, 8 parts of medium-carbon ferromanganese, 17 parts of tungsten carbide, 9 parts of nickel powder, 2.5 parts of rutile, 2 parts of ferrosilicon, and 5 parts of ferrosilicon. , 2 parts of magnesium oxide, 2.5 parts of fluorite, 0.6 parts of fluoride, and 23 parts of adhesive.

[0037] The ingredients of the second welding flux include: 65 parts of rosin, 12 parts of vaseline, 3 parts of hydrogenated abietyl alcohol, 5 parts of succinic acid, 1.5 parts of diethanolamine, and 2 parts of surfactant.

[0038] The thickness of the first flux layer in the electrode is 8 times the thickness of the second flux layer; the fluoride in the first flux layer is potassium fluoroti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com