Stop valve capable of dynamically sampling

A shut-off valve, dynamic technology, applied in the field of shut-off valves that can be dynamically sampled, can solve the problems of troublesome operation, small friction, large fluid resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

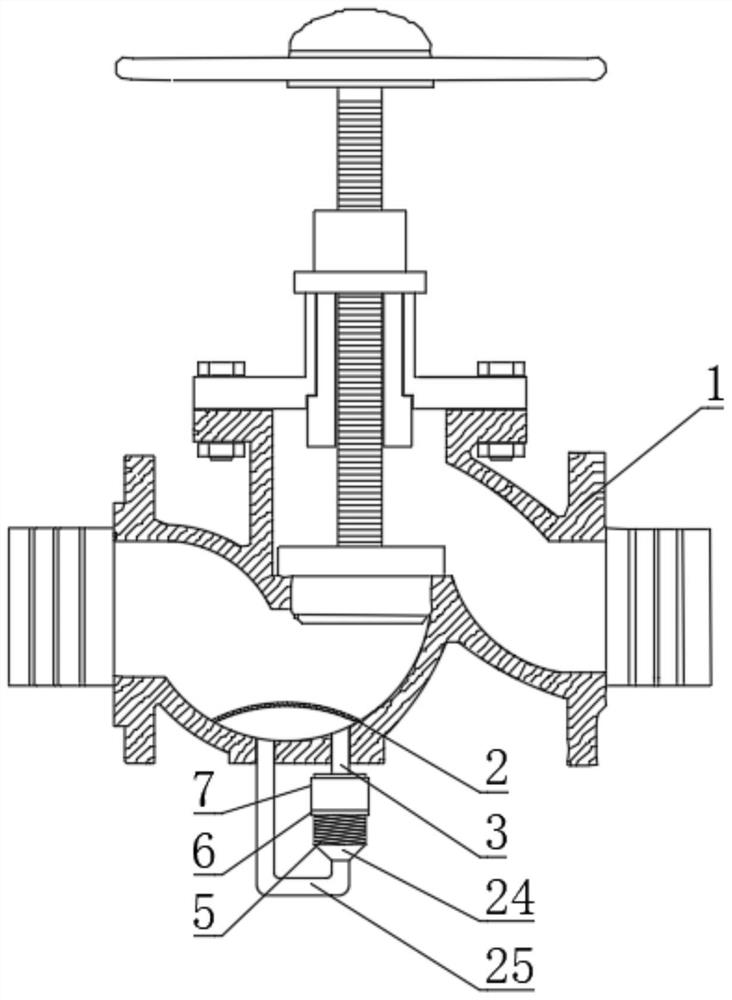

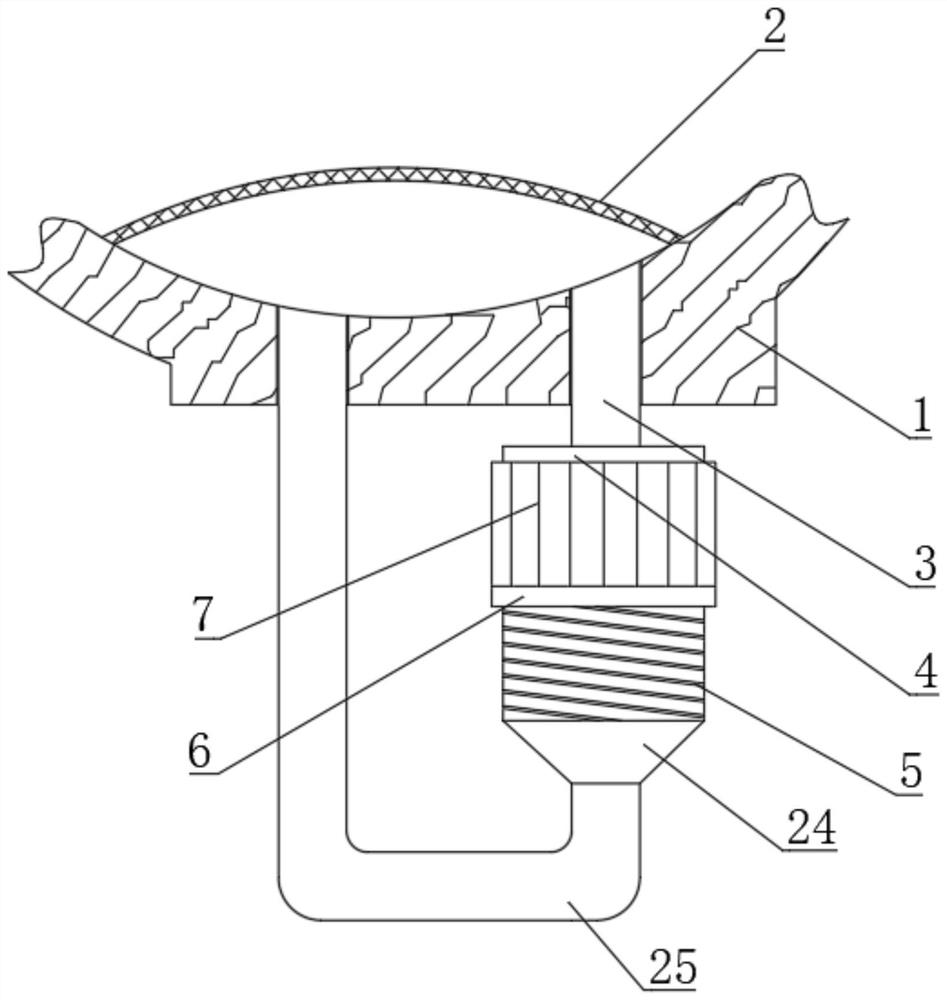

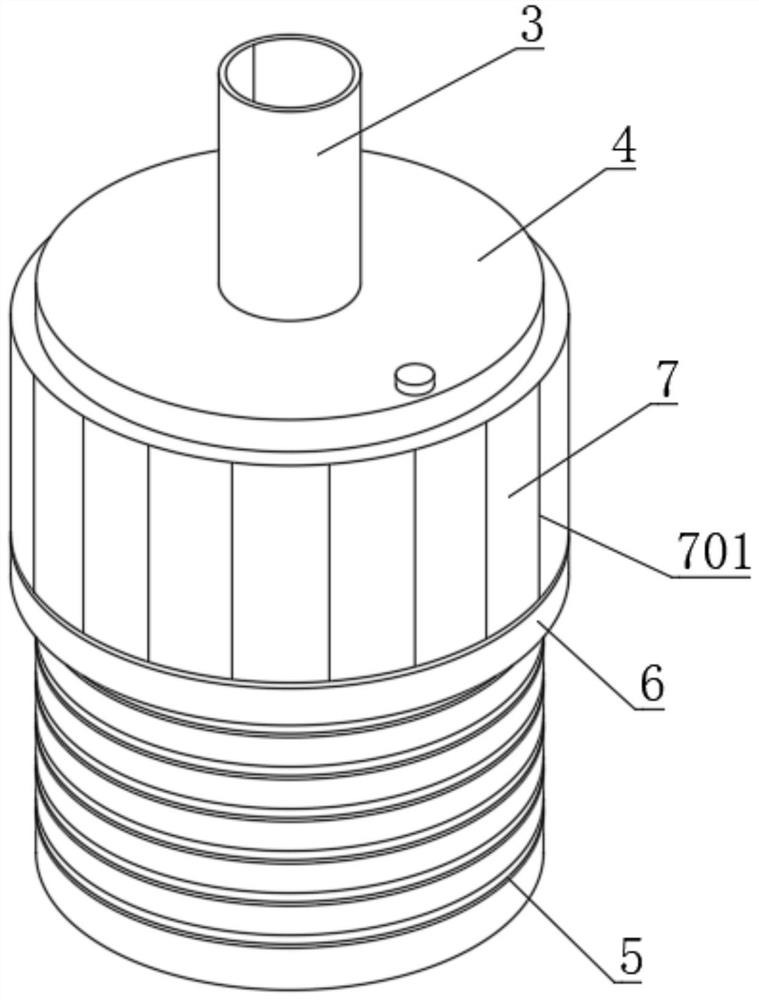

[0041] see Figure 1-6 , a globe valve capable of dynamic sampling, comprising a valve body 1, the inner bottom end of the valve body 1 is fixedly connected with an arc-shaped filter screen 2, and the inner bottom end of the valve body 1 is fixedly connected with a shunt pipe 3, and the shunt pipe 3 is located on the arc Below the filter screen 2, the lower end of the shunt pipe 3 is fixedly connected with an engaging column 4, and the outer peripheral surface of the connecting column 4 is dug with a thread groove 5, and the outer peripheral surface of the connecting column 4 is threadedly connected with an engaging ring 6, and the connecting ring 6 The upper end is fixedly connected with a sealing ring 7, and the inner wall of the sealing ring 7 is fixedly connected with a rubber extruded layer 8. The inner wall of the rubber extruded layer 8 fits the outer peripheral surface of the connecting column 4, and the outer peripheral surface of the connecting column 4 is excavated a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com