Floating boat body valve

A technology of hull and gate, applied in water conservancy engineering, marine engineering, coastline protection, etc., can solve problems such as sealing, dam flood disaster, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

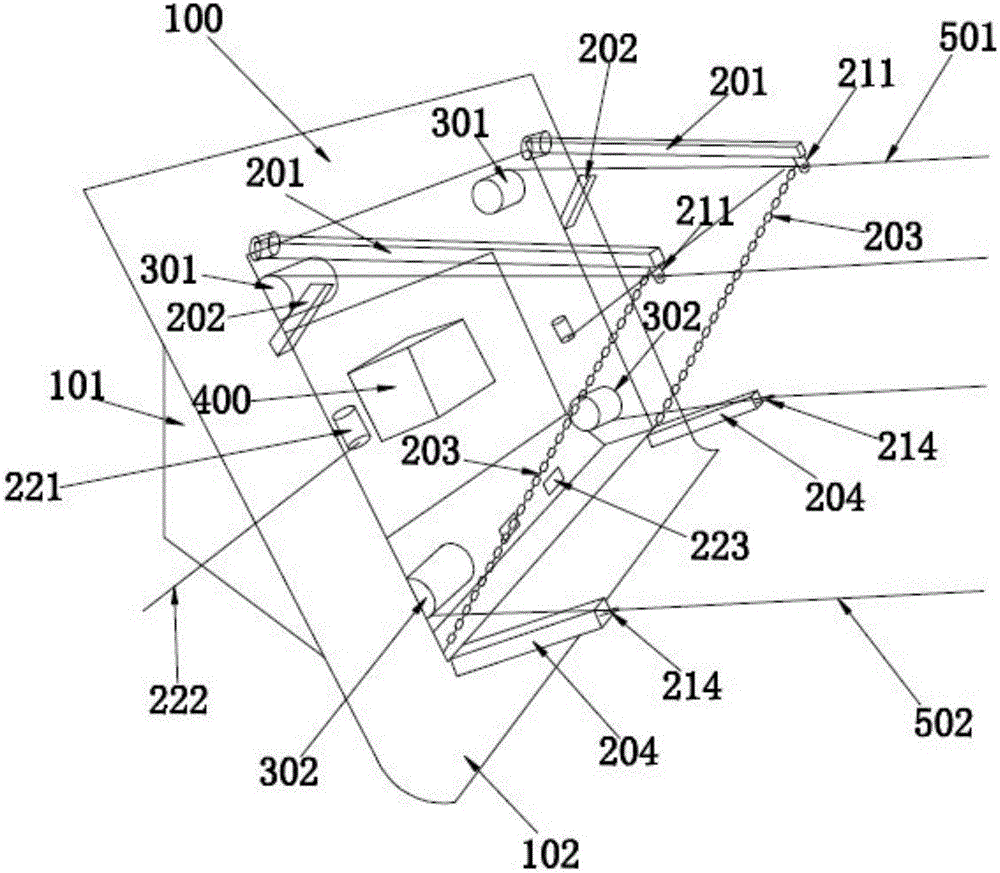

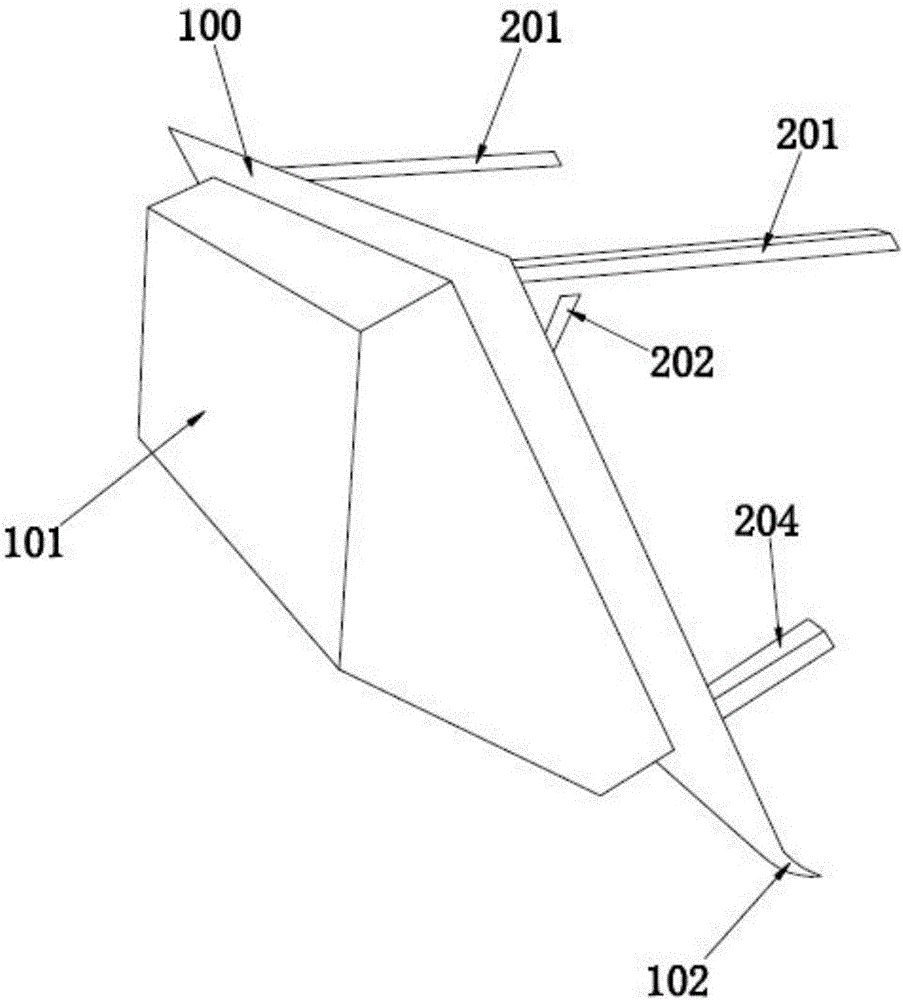

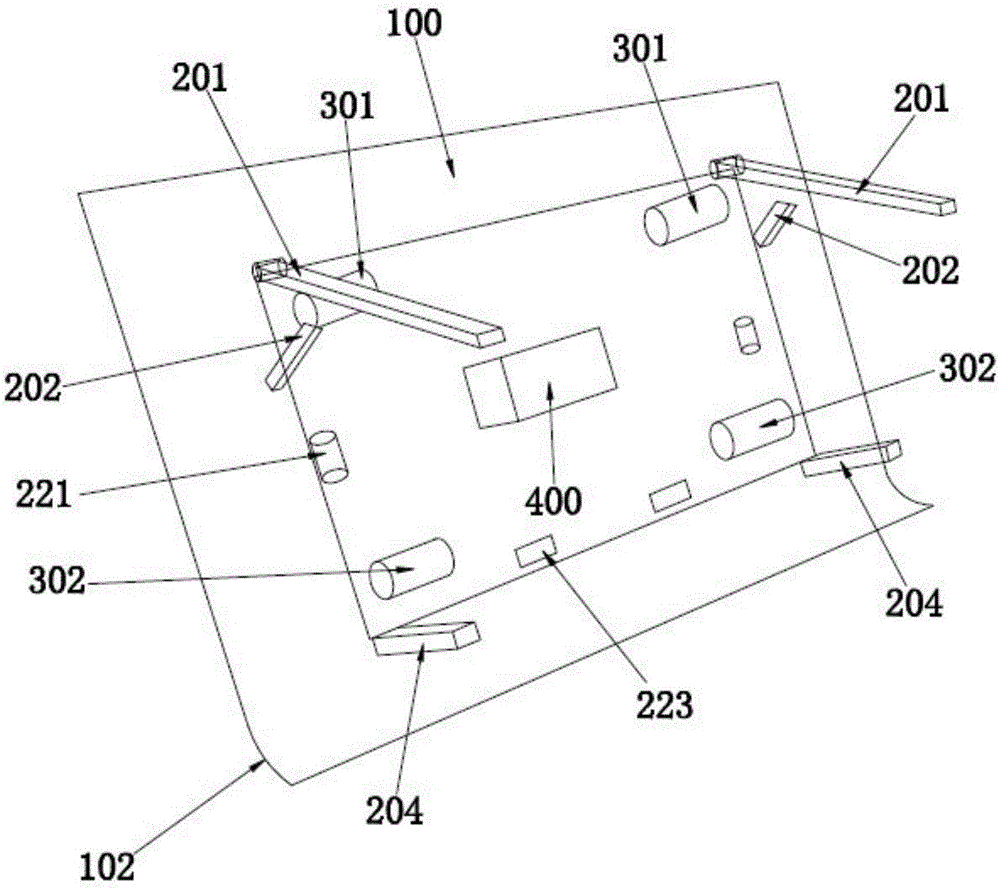

[0028] Such as Figure 1~3 shown, see figure 1 , a floating hull gate of the present invention includes

[0029] The docking plate 100 has a plate through hole in the middle;

[0030] buoyancy chamber 101, the outer end of which is sealed and fixed with the through hole of the plate;

[0031] A lever 201, one end of which is hingedly connected to the upper end of the buoyancy chamber 101, and the other end is provided with a lever collar 211;

[0032] Control column 202, its fixed end is hingedly connected with the middle part of the outer end of the buoyancy chamber 101, and its telescopic end overlaps with the middle part of the lever 201;

[0033] A stabilizing column 204, one end of which is connected to the lower end of the buoyancy chamber 101, and the other end is provided with a column rope ring 214;

[0034] Wherein, the inner upper end of the buoyancy chamber 101 is provided with an upper winch motor 301, the output shaft of the upper winch motor 301 is fixed to ...

Embodiment 2

[0050] The difference between this embodiment 2 and embodiment 1 is: see Figure 4 , the end of the lever 201 is connected to the lever collar 211 through a fine-tuning mechanism 500, and the fine-tuning mechanism 500 includes a square seat 501, a first bottom rod 511, a second bottom rod 512, a third bottom rod 513, a second bottom rod A middle seat 521, a second middle seat 522, a third middle seat 523, a first middle rod 531, a second middle rod 532, a third middle rod 533, a first push rod 541, a second push rod 542, a third push rod rod 543;

[0051] The end angle of described square seat 501 is fixed with the end of described lever 201, and the connection line of two opposite end angles of described square seat 501 is parallel with the length direction of described lever 201, and described square seat 501 is cube , the three surfaces of the square seat 501 away from the lever 201 are hingedly connected to one end of the first bottom bar 511, the second bottom bar 512, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com