Anti-seismic pole

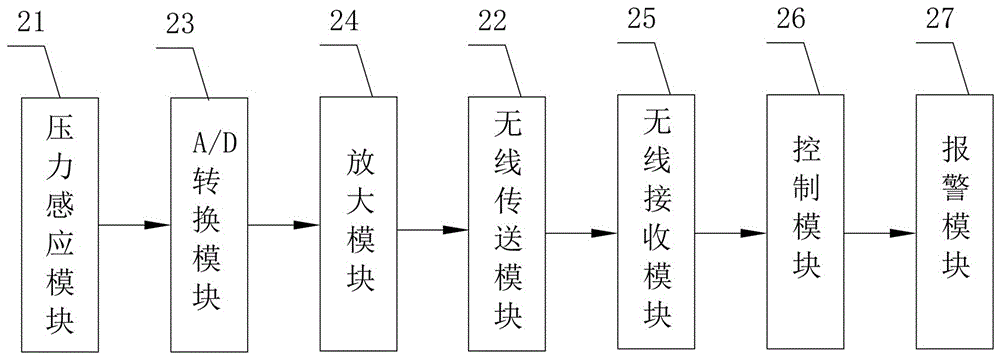

A technology of poles and shock-absorbing seats, applied in the field of transmission lines, can solve the problems of uneven settlement, easy breaking, time-consuming and laborious installation process, etc., to improve structural stability and reliability, reduce deflection or hard damage, The effect of preventing breakage or tipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

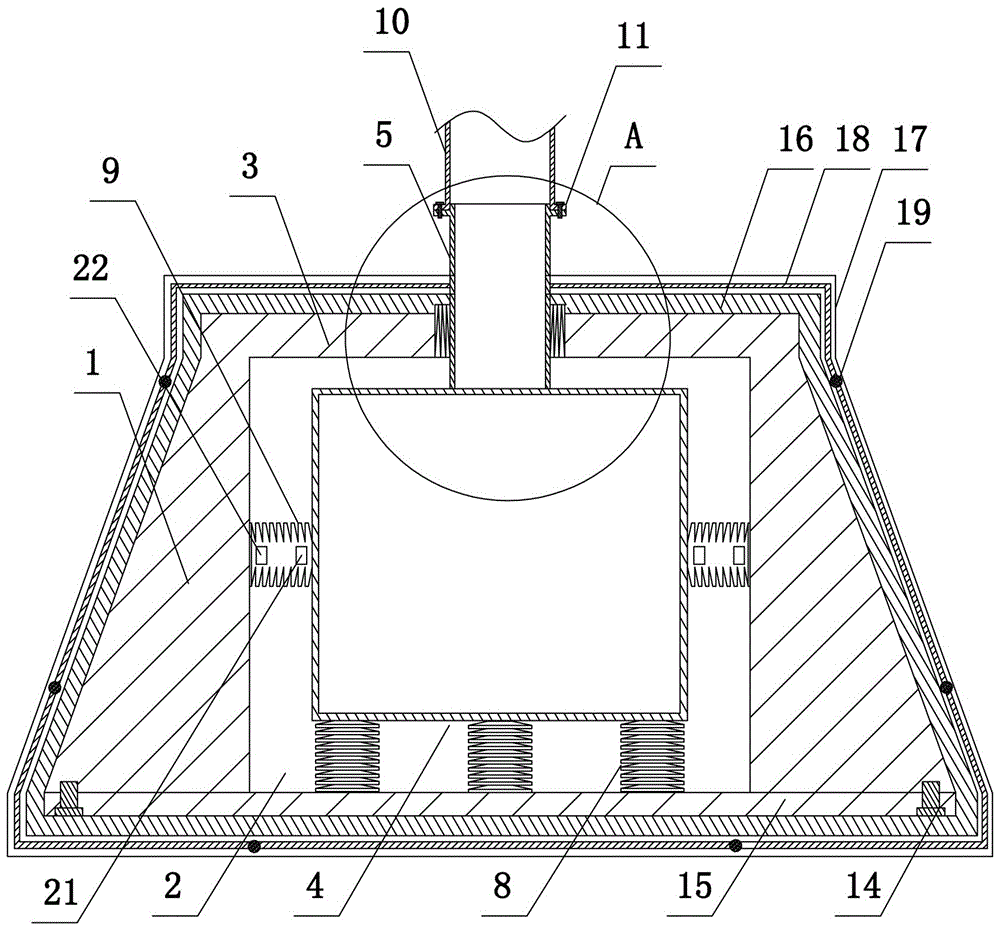

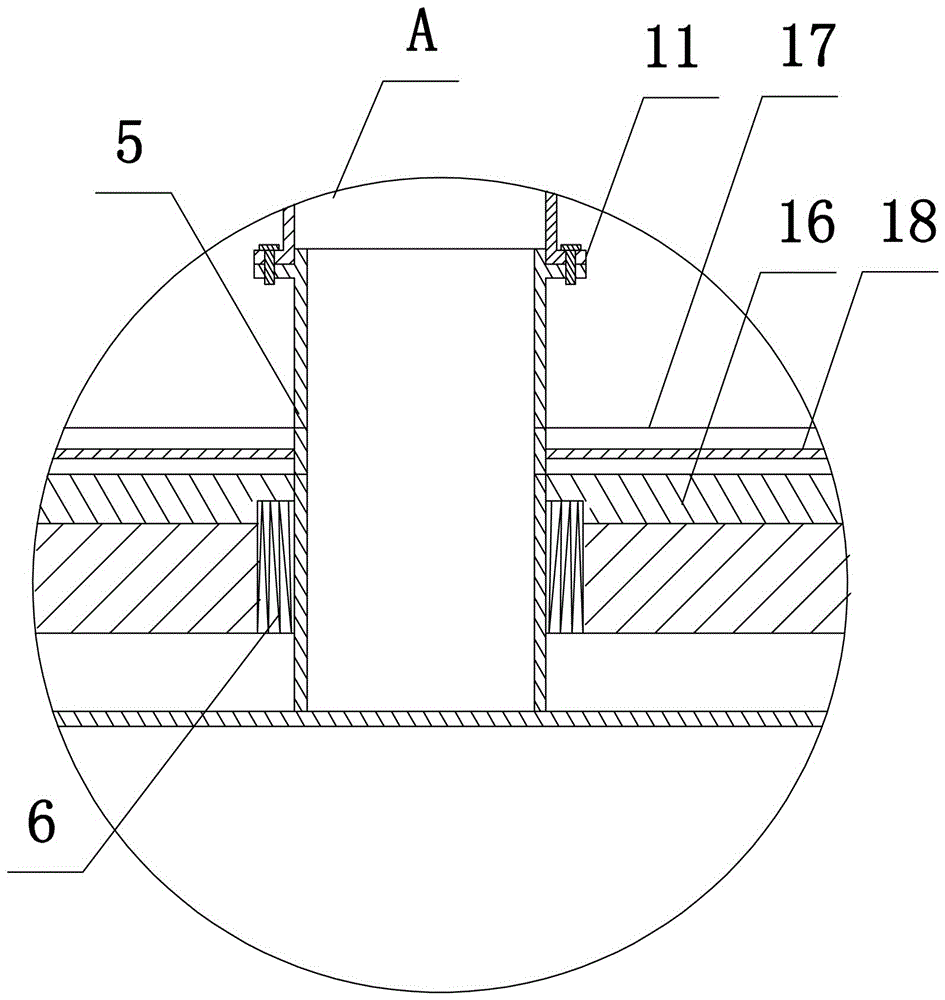

[0029] Such as Figure 1 to Figure 3 As shown, the present invention includes a pole main body 10, a moisture-proof casing and a shockproof mechanism arranged in the moisture-proof casing. The moisture-proof casing includes a symmetrically arranged front casing (not shown), a rear casing 16, and the front casing and the rear casing 16 are integrally formed. The second flange 17, the inner side of the second flange 17 of the front shell and the rear shell 16 is provided with a sealing strip 18, and the front shell and the rear shell 16 are fastened to each other and sealed and fastened by bolts 19;

[0030]The anti-shock mechanism includes a support base and a shock-absorbing structure, including a support base 1, a shock-absorbing structure, and a pole main body 10. The pole main body 10 can use a columnar hollow steel pipe, and the support base 1 is a frustum-shaped structure. , the accommodation cavity 2 is a rectangular parallelepiped columnar structure, the upper end surfa...

Embodiment 2

[0033] The present invention includes a pole main body 10, a moisture-proof casing and a shock-proof mechanism arranged in the moisture-proof casing, the moisture-proof casing includes a symmetrically arranged front casing and a rear casing 16, and the front casing and the rear casing 16 are integrally formed with a second flange 17, and the front casing A sealing strip 18 is provided on the inner side of the second flange of the rear shell 16, and the front shell and the rear shell 16 are fastened to each other by bolts 19 to seal and fasten them;

[0034] The anti-shock mechanism includes a support base and a shock-absorbing structure, including a support base 1, a shock-absorbing structure, and a pole main body 10. The pole main body 10 can use a columnar hollow steel pipe, and the support base 1 is a frustum-shaped structure. , the accommodation cavity 2 is a rectangular parallelepiped columnar structure, the upper end surface of the supporting base 1 is integrally formed w...

Embodiment 3

[0037] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 5 As shown, four first protrusions 12 (two are shown in the figure) are arranged on the outer wall of the shock absorber 4, four second protrusions 13 are arranged on the inner wall of the accommodation cavity 2, and the air spring 9 is four and its The two ends are respectively socketed with the first protrusion 12 and the second protrusion 13 . During installation, the air spring 9 is retracted by the hydraulic or pneumatic clamping device in the prior art, and it is sleeved on the first protrusion 12 and the second protrusion 13. When an earthquake occurs, this structural design is conducive to improving the air spring. 9 structural stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com