Spinning type manually-operated hydraulic steel bar cutting-off device capable of working in two directions

A bidirectional working and cutting device technology, applied in the field of steel cutting equipment, can solve the problems of slow cutting speed, complicated adjustment, low efficiency, etc., and achieve the effect of wide application range and faster cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

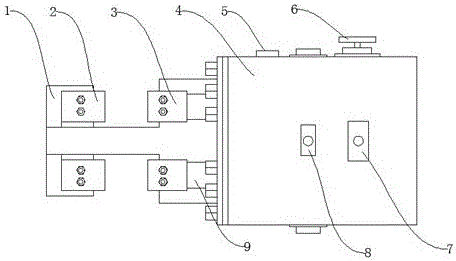

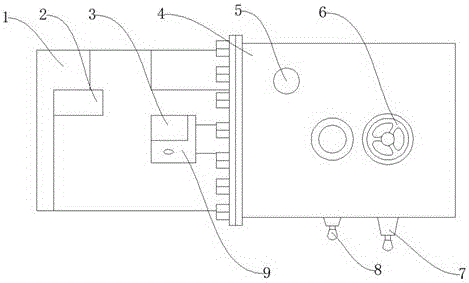

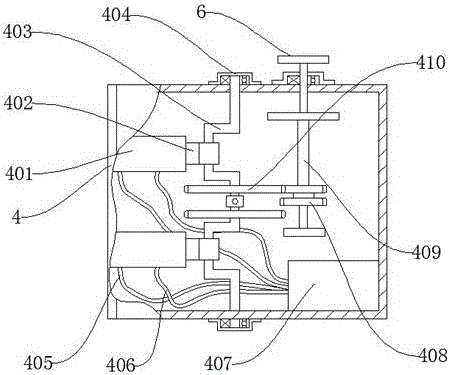

[0017] Such as Figure 1-Figure 3 As shown, a spinning type manual hydraulic steel bar cutting device that can work in both directions includes a knife seat 1 and a control box 4. A fixed knife 2 is installed on the knife seat 1, and a moving knife 3 is installed next to the fixed knife 2. , the moving knife 3 is used to cut steel bars, the control box 4 is arranged next to the knife seat 1, and the front end of the control box 4 is provided with a hydraulic rod 9, and the hydraulic rod 9 is used to control the moving knife 3 , the control box 4 is provided with an oil discharge valve 5, and a hand wheel 6 is provided beside the oil discharge valve 5, and the hand wheel 6 is used to load hydraulic oil, and a reversing rod 7 is provided on the side of the control box 4 , the reversing rod 7 is used to switch the use of the fixed knife 2, and a linkage rod 8 is arranged besi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com