Crawler shot blasting cleaner material feeding mechanism

A technology of feeding mechanism and crawler shot blasting, which is applied in the direction of abrasives, used abrasives processing devices, metal processing equipment, etc., can solve the problems of complicated structure and high production cost, and achieve the effect of easy operation and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

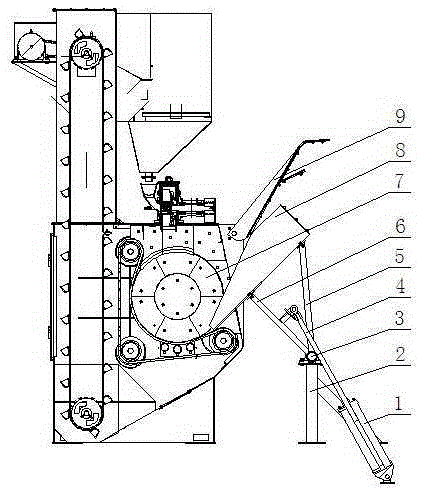

[0009] The invention will be further described below in conjunction with the embodiments of the accompanying drawings.

[0010] As shown in the figure, a flat-bottomed feeding hopper 8 is installed at the front door 9 of the cleaning chamber. The lower end of the rear flipping rod 5 is connected, and the lower support frame 2 is installed, the flipping shaft 3 is arranged between the front flipping rod 6, the rear flipping rod 5 and the support frame 2, and the outer side of the support frame 2 is equipped with a feeding cylinder 1. The cylinder rod 4 of the feed cylinder 1 is connected with the front turning rod 6.

[0011] When feeding, put the workpiece into the feeding hopper 8 and open the front door 9 of the cleaning chamber, start the feeding cylinder 1 through the cylinder rod 4, push the front turning rod 6 to drive the rear turning rod 5 to turn forward around the turning shaft 3, and make the feeding The rear part of the bucket 8 is upturned and the workpiece is po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com