Dynamic experimental testing system of pantograph

A technology of dynamic testing and testing system, applied in railway vehicle shape measuring instrument, railway car body parts, overhead lines, etc., can solve the problems of unstable power supply module, large signal interference, no traction of kilometer signal and network current signal, etc. , to achieve the effect of convenient operation, reduced complexity and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with example the present invention is described in further detail. However, the invention is not limited to the examples given.

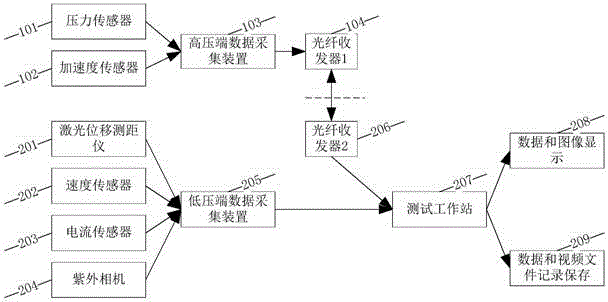

[0023] Such as figure 1 As shown, the pantograph dynamic test system of this embodiment includes: a high-voltage end data acquisition device 103 , a low-voltage end data acquisition device 205 , and a test workstation 207 .

[0024] The high-voltage end data acquisition device 103 has a pressure sensor 101, an acceleration sensor 102, and a first signal transfer box, an IMC data collector, a first optical fiber transceiver 104 and a second optical fiber transceiver 206 connected in sequence, the pressure sensor 101 and the acceleration sensor The signal output end of the sensor 102 is connected to the signal transfer box; a pressure sensor is installed between the two ends of the carbon slide plate of the pantograph and the supporting bow plate to detect the vertical force between the pantograph and catenary on the carbo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap