Material collecting method and system based on indexing rotating disc

An indexing turntable and collection system technology, applied in the field of counting machines, can solve the problems of affecting the production capacity of the counting machines and high mutual friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

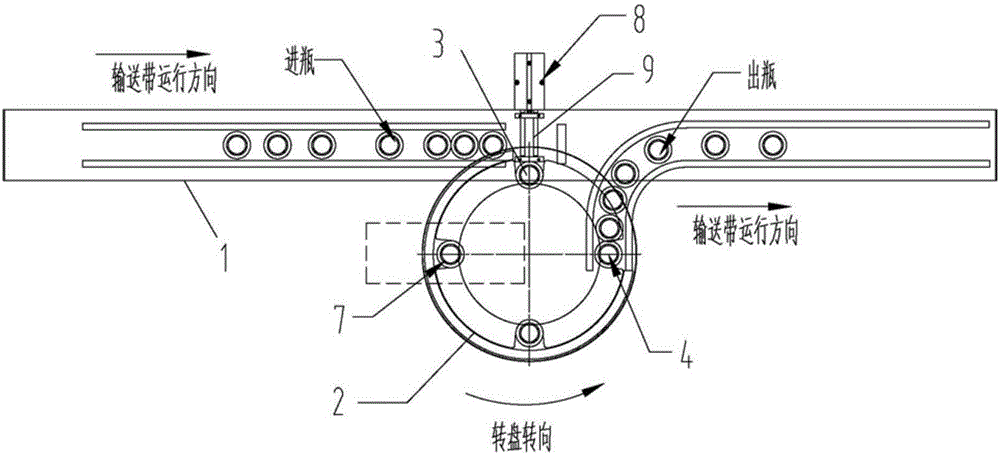

[0055] Embodiment 1, as figure 1 As shown, a method for collecting discrete materials based on an indexing turntable 2,

[0056] Step 1, the collection bottle enters the bottle feeding station 3 of the indexing turntable 2,

[0057] Step 2, the indexing turntable 2 rotates to transport the collection bottle to the blanking station 7 of the indexing turntable 2,

[0058] Step 3: The material is divided into piles according to the target quantity by the counting machine and sent to the feeder 6, and the feeder 6 outputs the material to the collector 5 corresponding to the blanking station 7;

[0059] Step 4: During the period when the indexing turntable 2 rotates to transport the collection bottle from the blanking station 7 to the bottle discharge station 4, the concentrator 5 moves synchronously with the indexing turntable 2 and continuously puts all the materials into the collection bottle; the collection bottle Leave the indexing turntable 2 when reaching the bottle output...

Embodiment 2

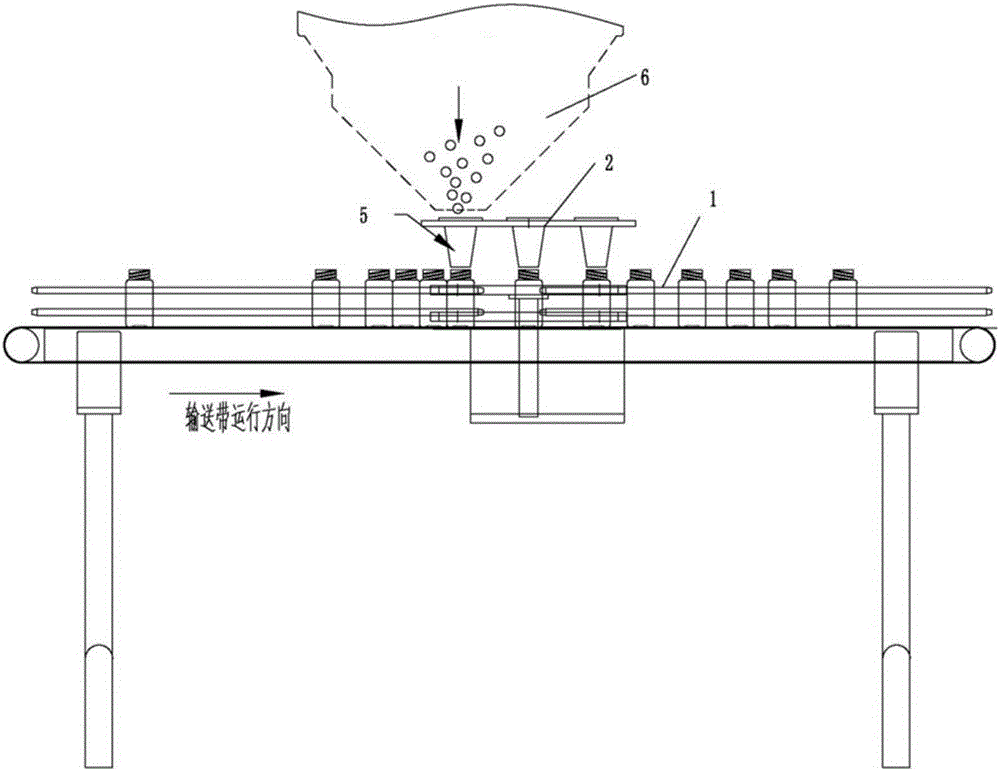

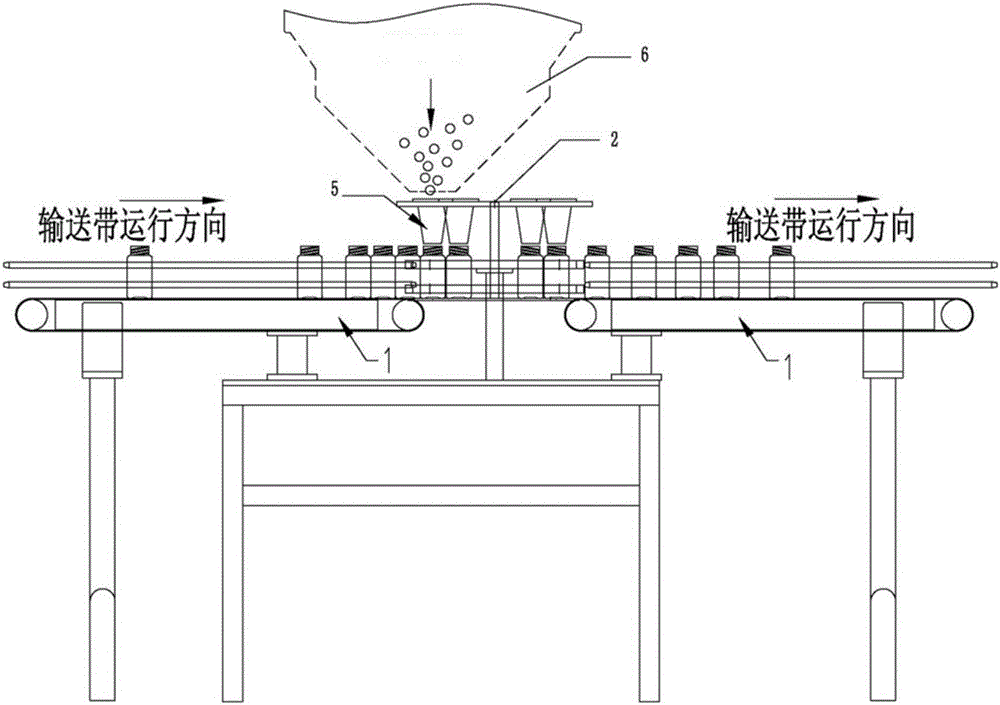

[0065] Embodiment 2, as image 3 , Figure 4 , Figure 5 Shown, a kind of material collecting method based on indexing turntable 2,

[0066] Step 1, the collection bottle enters the bottle feeding station 3 of the indexing turntable 2,

[0067] Step 2: The material is divided into piles according to the target quantity by the counting machine and then sent to the injector 6; the injector 6 sends the material to the concentrator 5 corresponding to the bottle feeding station 3 of the indexing turntable 2,

[0068] Step 3: While the indexing turntable 2 rotates to transport the collection bottle from the bottle inlet station 3 to the bottle outlet station 4, the concentrator 5 moves synchronously with the collection bottle and continuously puts all the materials into the collection bottle; the collection bottle reaches the bottle outlet Leave the indexing turntable 2 at station 4;

[0069] Step 4: When the collecting bottle leaves the bottle feeding station 3; the next collec...

Embodiment 3

[0071] Example 3 as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 as shown,

[0072] A material collection system based on an indexing turntable 2, comprising

[0073] The indexing turntable 2 has at least two indexing positions, including the bottle inlet station 3 and the bottle outlet station 4; the collected bottles enter the bottle inlet station 3 and are fixed, and the index turntable 2 is output when it rotates to the bottle outlet station 4 collection bottle;

[0074] The feeder 6 is used to receive the materials that are piled up by the counting machine according to the target quantity, and output them to the concentrator 5;

[0075] A concentrator 5, each index position of the indexing turntable 2 is correspondingly provided with a concentrator 5, and the converging device 5 moves synchronously with the indexing turntable 2, and the outlet of the concentrator 5 remains within the corresponding index position. Above the bottle mouth of the collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com