Method for producing large circulation jacquard fabric using dobby machine

A dobby loom and fabric technology, applied in the field of fabric weaving, can solve the problems of low efficiency of jacquard loom, failure to meet the requirements of a single cycle, and insufficient number of single cycles of the text plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

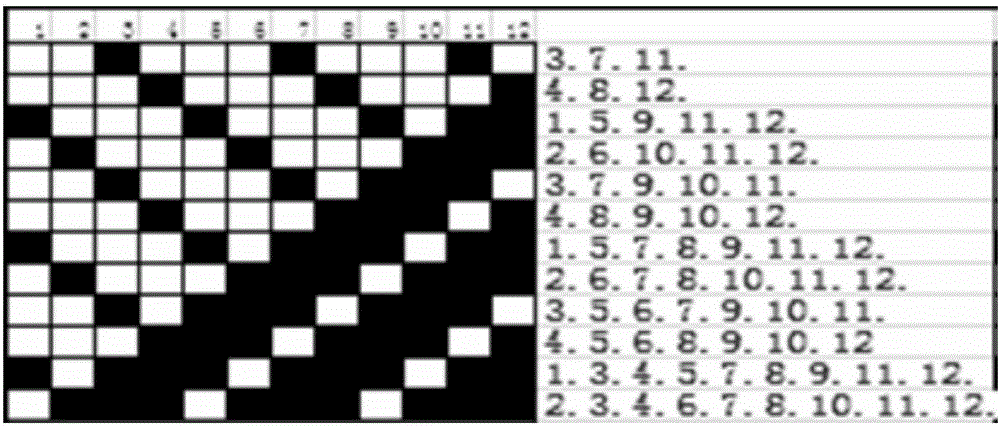

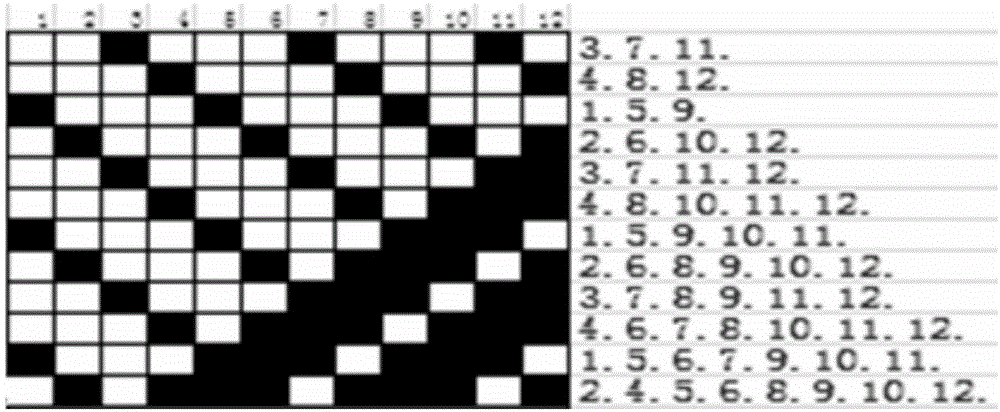

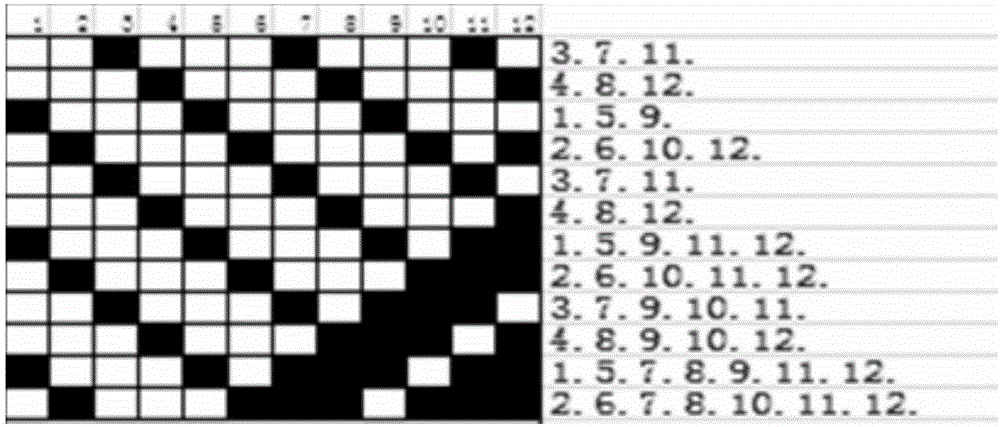

Image

Examples

Embodiment Construction

[0019] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0020] As a specific embodiment of the present invention, the present invention relates to a method for producing large cycle jacquard fabrics with a dobby loom, comprising the following steps:

[0021] ① Renovation of the dobby loom machine: add the main board of the machine control system, add two sets of EEPROM, IC2 and IC3 to the main board, and form a series connection with IC1 in the previous version; re-implant a set of programmed control chips , this control chip combines IC1, IC2, IC3 three EEPROMs that can be stored, and implants a program that can write 9999 text cycles; then disconnect the output of the previous text to the server, and replace it with this new one. output on the motherboard;

[0022] ②Jacquard pattern design: choose N-40 / 34FDFDY as the warp yarn, N-40 / 34SDFDY as the weft yarn, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com