Novel steel rail assembly

A technology of rails and components, applied in the direction of rails, tracks, roads, etc., can solve the problems of rail end deformation, accelerated wheel wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The rail assembly of the present invention can be obtained in the following manner.

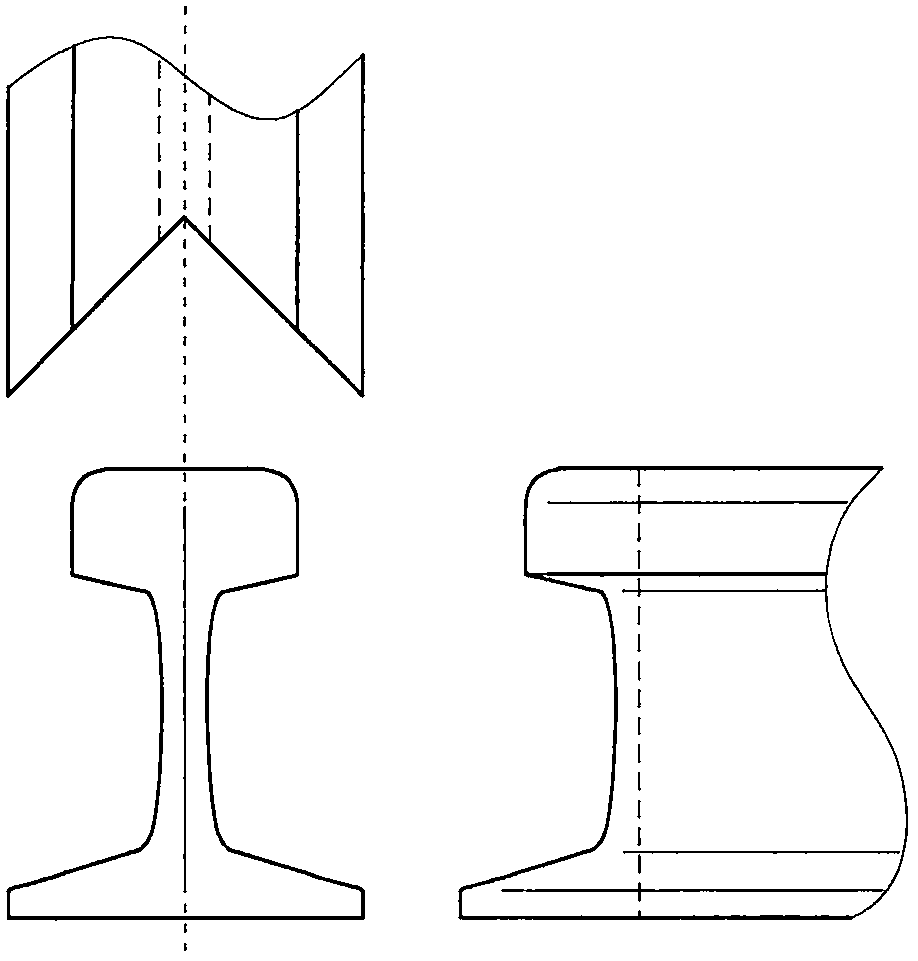

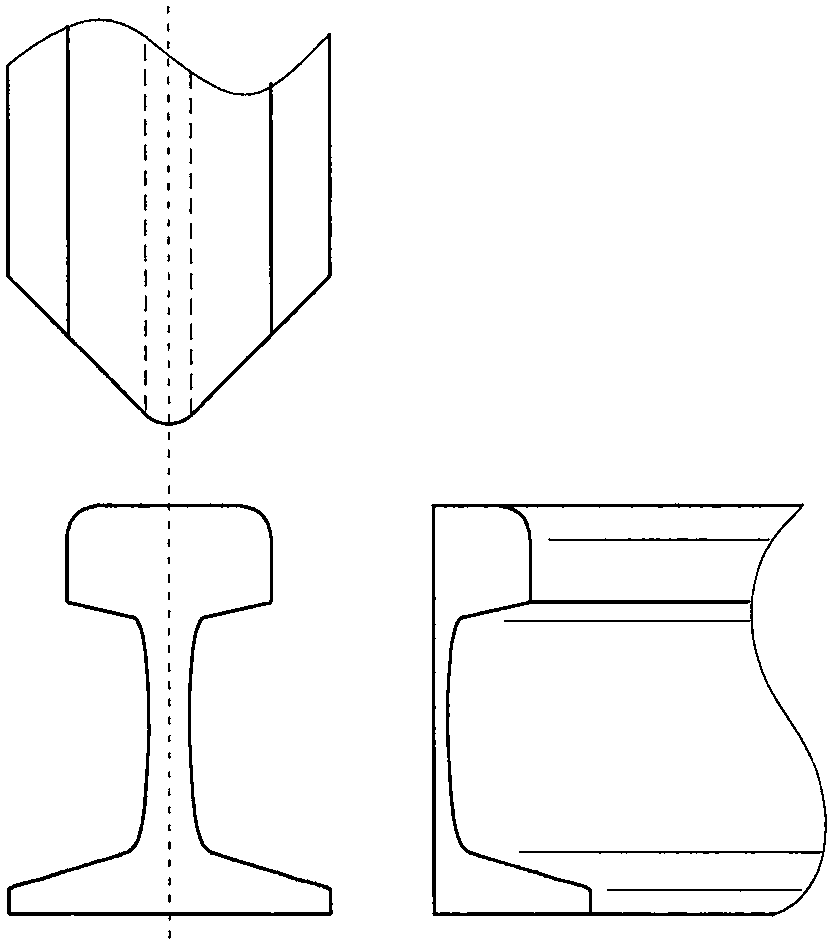

[0015] For two rails connected to each other, follow the figure 1 with figure 2 Cut as shown. After fixing the cutting equipment and the rail, adjust the angle of the cutting tool, and cut from both sides of the rail to the center of the rail, so that the sharp corner is just on the center line of the rail surface. The included angle between the cutting lines on both sides and the centerline of the longitudinal axis of the rail should be the same.

[0016] Grinding equipment is used to grind the sharp corner of the protruding end of the rail to eliminate the sharp corner.

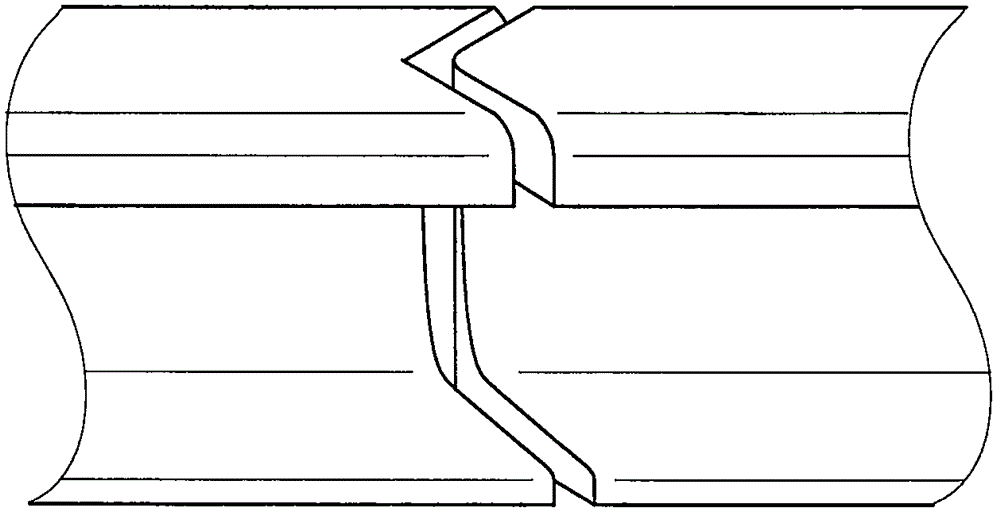

[0017] according to image 3 As shown, the protruding and concave parts of the two sections of rails are docked, appropriate rail gaps are reserved, and insulating materials are installed to ensure that the centerlines of the two sections of rails are consistent. Drill holes and clamp the rails with fishplates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com