A method of foundation pit support

A technology for foundation pit support and support piles, applied in excavation, foundation structure engineering, construction, etc., can solve the problems of difficult adaptation and high deformation requirements of support structures, and achieve the effect of small horizontal displacement and reduced length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

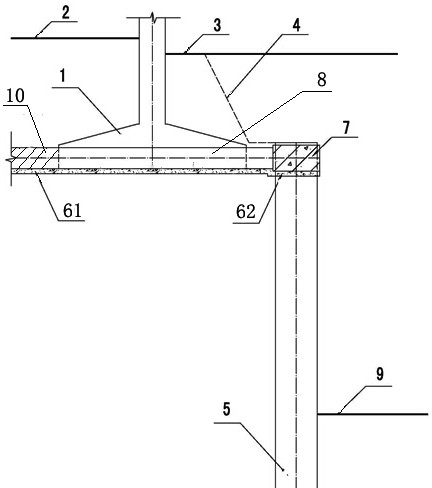

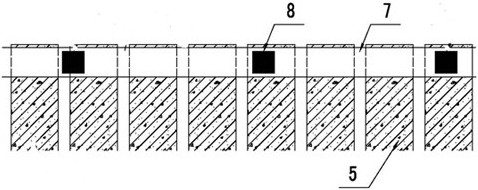

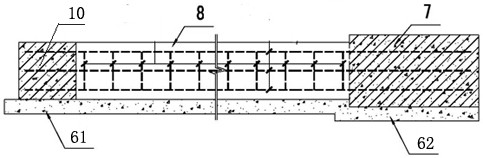

[0025] Such as figure 1 , 2 , as shown in 3,

[0026] 1. Measurement and setting out: at the proposed site, according to the foundation pit support requirements, carry out the construction site measurement and setting out, and determine the specific position of the supporting pile working face and the excavation sideline of the foundation pit 4;

[0027] Excavation site: Excavate the earthwork above the supporting pile working face, level the site according to relevant requirements, and mark the center line of the pile position;

[0028] Pile driver drilling in place: transport the pile driver to the construction site, and carry out drilling operations according to the construction sequence;

[0029] Lower reinforcement cage: tie and roll the steel bars in the support piles, and place them in the drilled support pile holes;

[0030] Pouring concrete for supporting piles: according to the regulations, pour concrete into the hole of supporting pile 5 from the bottom of the ho...

Embodiment 2

[0041] A foundation pit support method, comprising the following steps,

[0042] 1. On the proposed site, according to the support requirements, carry out the survey and setting out of the construction site, determine the specific position of the working face of the support piles and the excavation sideline of the foundation pit, and drive the support piles;

[0043] 2. Clean up the pile head, and remove the excess concrete within the range of the pile top as a crown beam and the concrete that does not meet the compactness requirements;

[0044] 3. In the existing buildings and structures, according to the original construction drawings of the foundation and combined with the actual situation on the site, determine the position of the caps of the existing buildings and structures, and determine the position of a tension beam on both sides of the caps,

[0045] 4. Excavate the foundation groove of the beam,

[0046] 5. Texturize the contact surface of existing buildings and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com