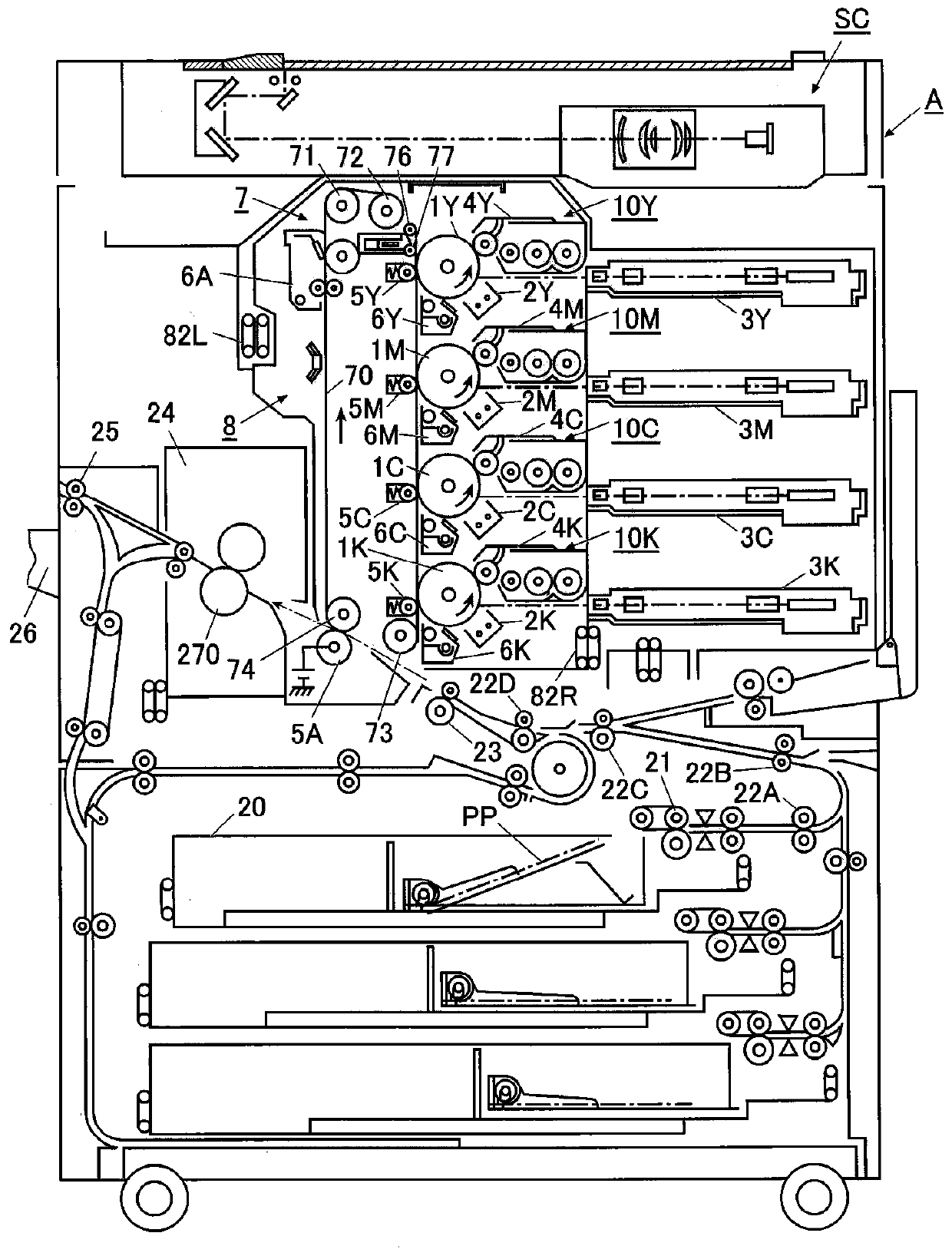

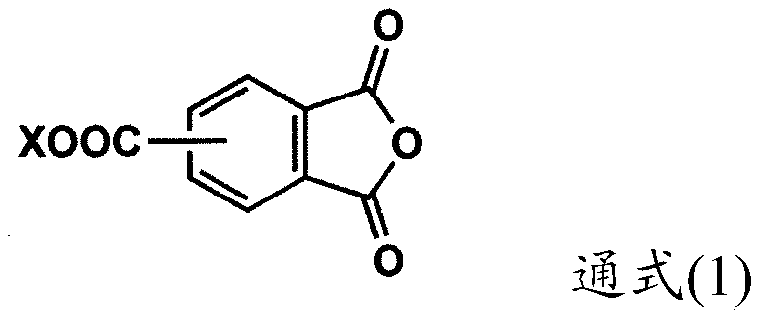

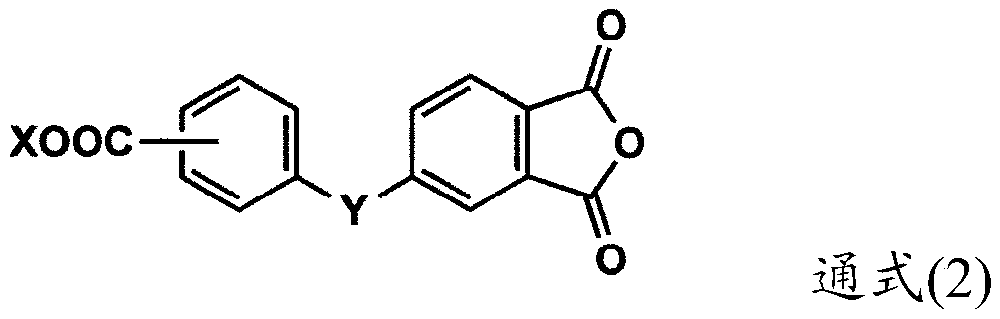

Intermediate transfer belt and image forming apparatus

An intermediate transfer belt and image technology, which is applied to the electrical recording process using the charge pattern, equipment and instruments for the electric recording process using the charge pattern, and can solve the problem of reduced strength, insufficient improvement in durability, and changes in resistance, etc. problem, achieving excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0191] Hereinafter, the present invention will be specifically described with reference to examples, by which the present invention is not limited. It should be noted that, in the examples, unless otherwise specified, the expression "part" or "%" is used to represent "part by weight" or "% by weight".

[0192] >

[0193] [Manufacture of intermediate transfer belt 1]

[0194]

[0195] A specified amount of the dispersant 1 having a block polymer structure of the present invention (TERPLUS D2015 manufactured by Otsuka Chemical Co., Ltd.) was dissolved in N-methylpyrrolidone (NMP), and acidic CB (acidic carbon black: Mitsubishicarbon black MA7 (manufactured by Mitsubishi Chemical Corporation) was stirred, and then carbon black was dispersed by a ball mill to prepare a carbon black dispersion containing 8 parts by mass of dispersant 1 per 100 parts by mass of carbon black.

[0196]

[0197] Solutions were prepared such that polyamideimide varnish HR-11NN (manufactured by Toy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com