Split type bearing assembly

A bearing assembly, split type technology, applied in the direction of bearing components, rigid support of bearing components, shafts and bearings, etc., can solve the problem of high error rate and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

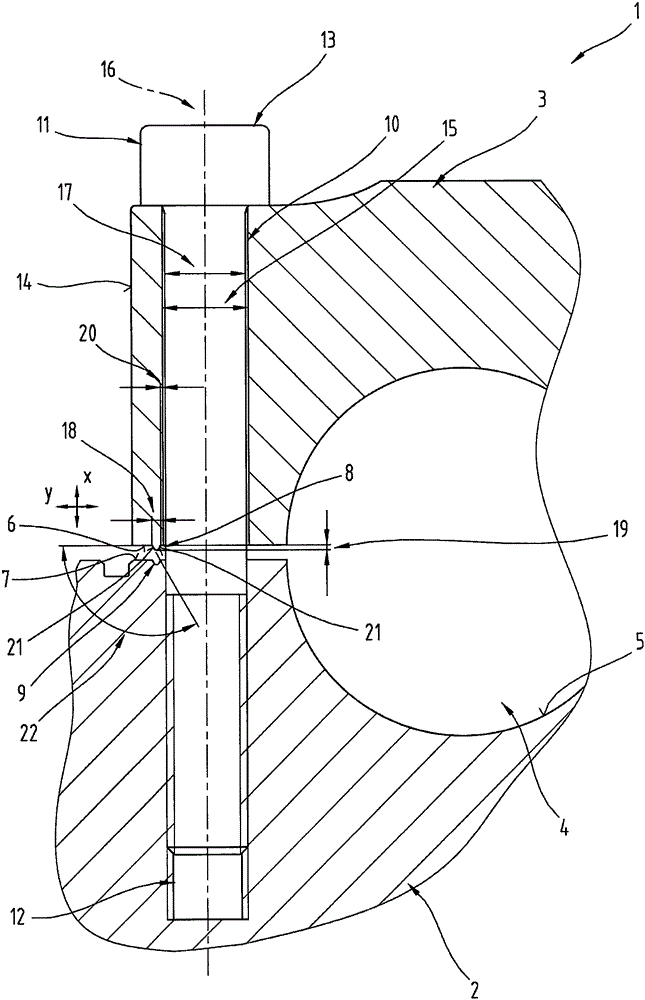

[0015] It should be noted that in the different embodiments described, the same reference numerals or the same component names represent the same components, and thus the disclosure contained in the entire specification can be referred to as the same component names by the same reference numerals. are applied to the same components. In addition, selected position information, such as top, bottom, side, etc., which are directly described and shown, can be similarly transferred to a new position by position change. exist figure 1 In is a cross-section of a split bearing assembly 1, eg for a machine housing of a reciprocating engine, not shown in the assembled state. The bearing assembly 1 includes a bearing seat 2 and a bearing cover 3 . Described bearing cap 3 and described bearing seat 2 have a bearing hole 4. The bearing bore 4 serves to accommodate a plain bearing, in particular a plain bearing shell, in this example a crankshaft can be accommodated. But it is also possi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com