Assembly system for automobile seat slide rail holder

A car seat slide rail and assembly system technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low production cost, improve production efficiency, reduce error rate, and achieve the effect of correct assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

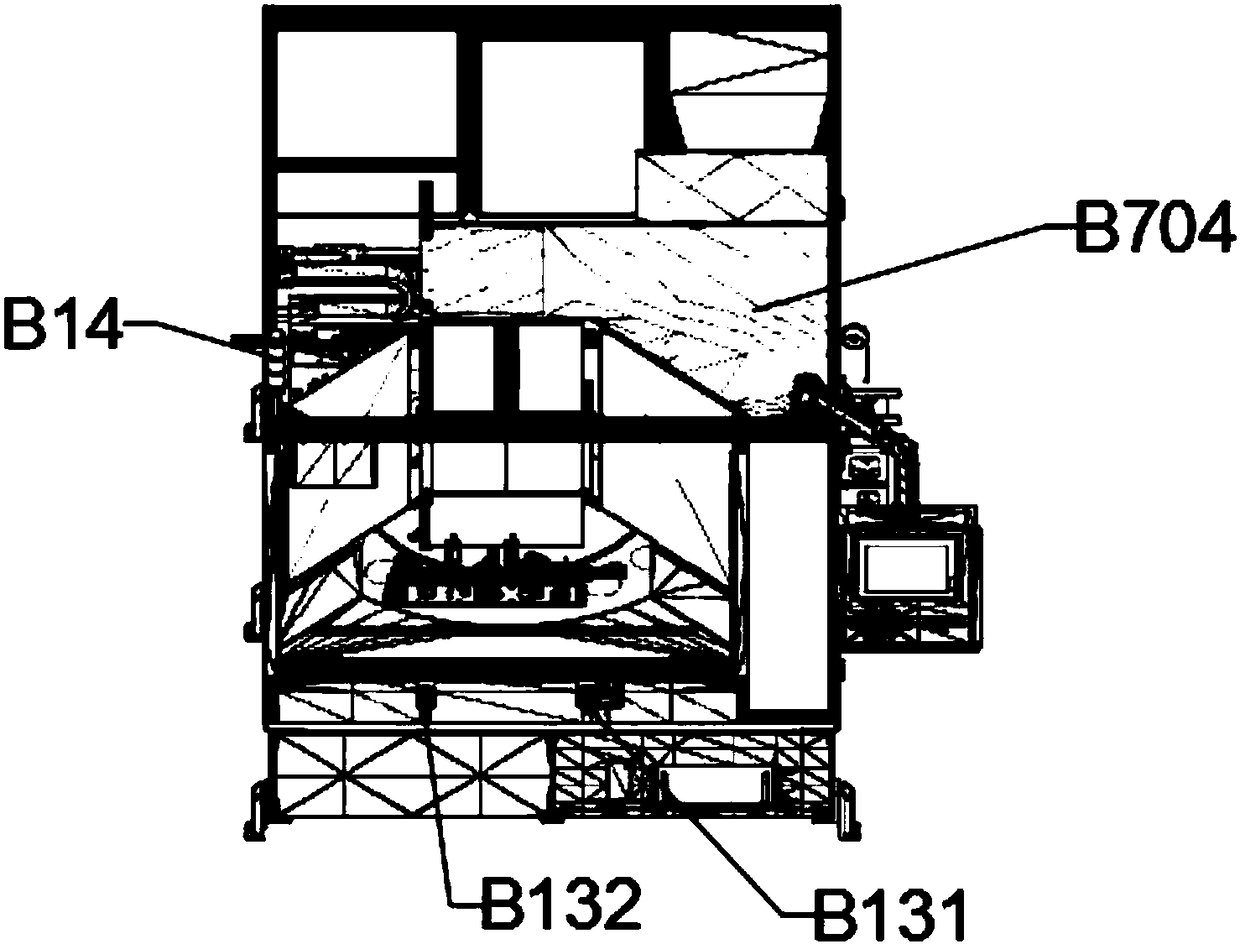

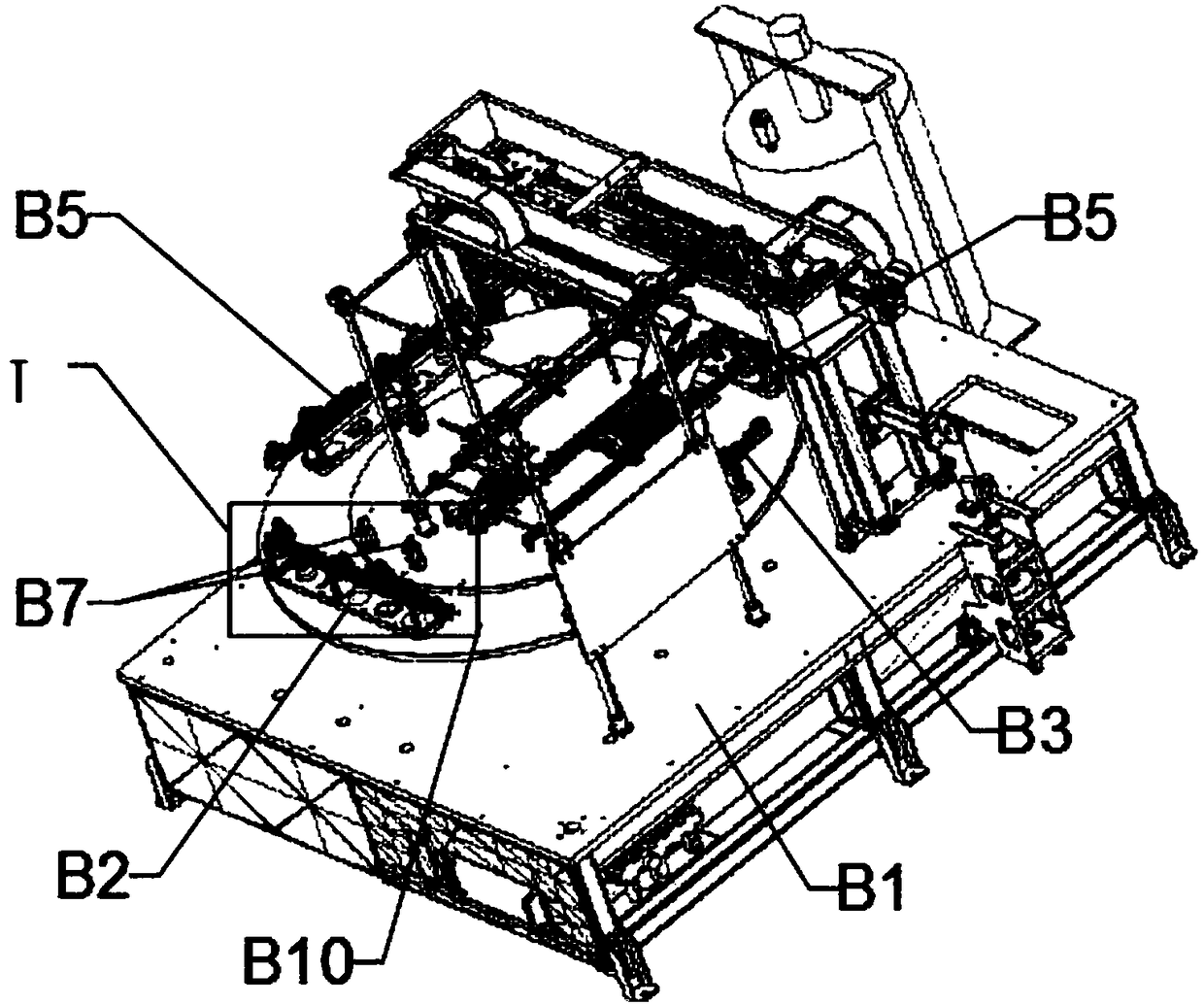

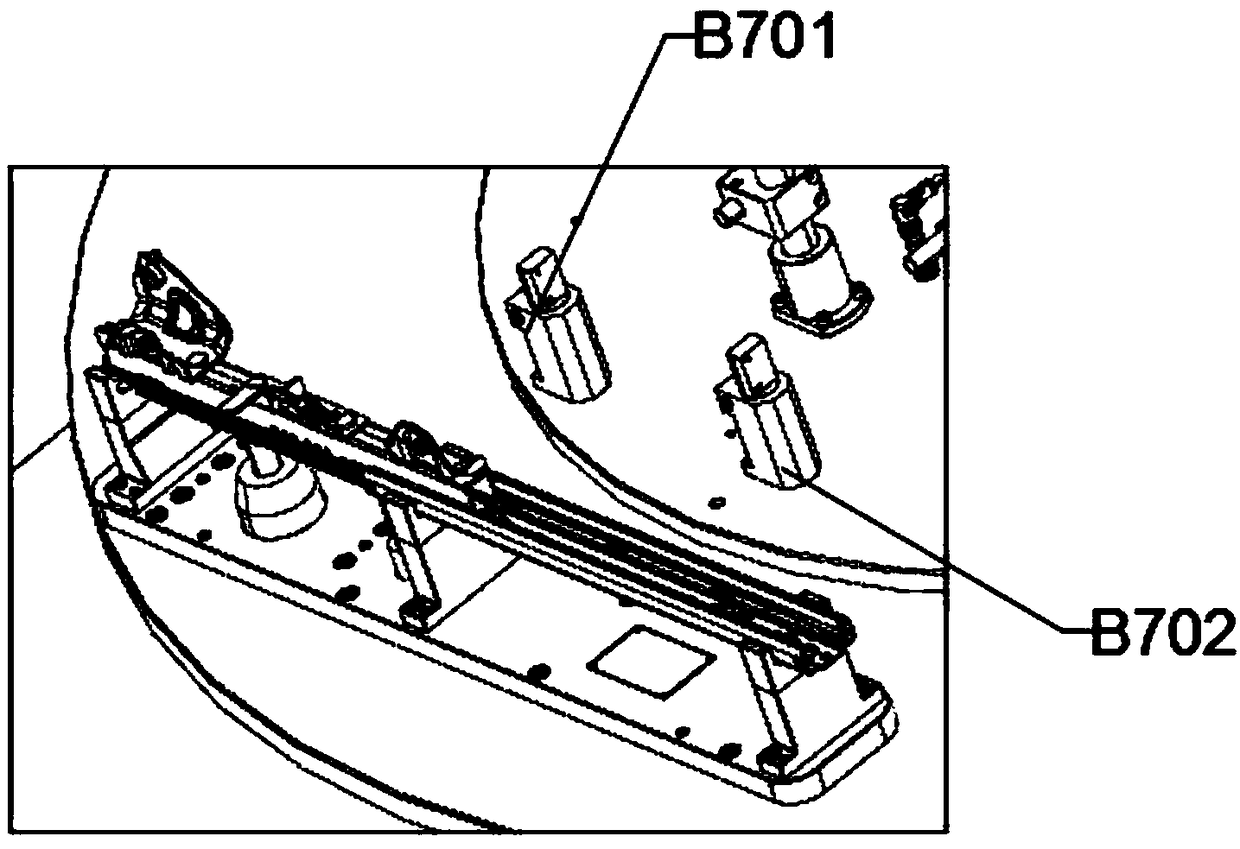

[0042] Such as Figure 1 to Figure 19 As shown in the figure, an automobile seat slide rail cage assembly system includes a machine B1, on which a cage pre-installation station B2, a cage pre-installation detection station B3, and a cage pre-installation station B3 are arranged on the machine counterclockwise. The rail push-in station B4 and the off-line station B5, the cage pre-installation device B6 is installed corresponding to the cage pre-installation station on the machine; the pre-installation detection device B7 is installed corresponding to the cage pre-installation detection station; There is an inner and outer rail push-in device B8 corresponding to the push-in position of the inner and outer rails of the upper cage; a boss B9 is arranged in the middle of the machine table, and a station indexing plate B10 is arranged on the outer edge of the boss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com