Self-closing liquid level observer capable of regulating center distance

A center distance, self-closing technology, applied in liquid level indicators, liquid/fluid solid measurement, instruments, etc., can solve problems such as center distance cannot be adjusted, liquid level observer leakage, center distance deviation, etc., to reduce leakage risk, savings, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

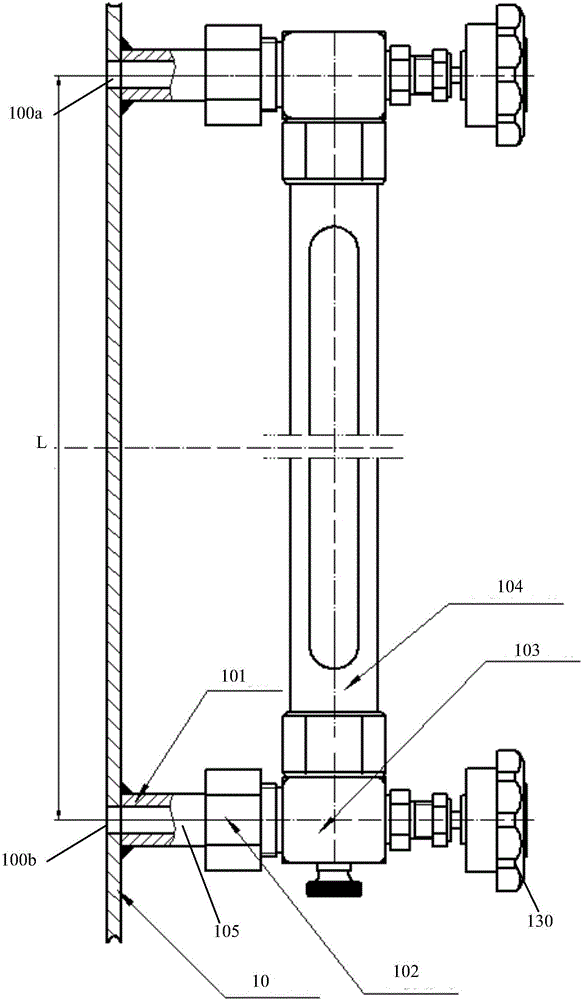

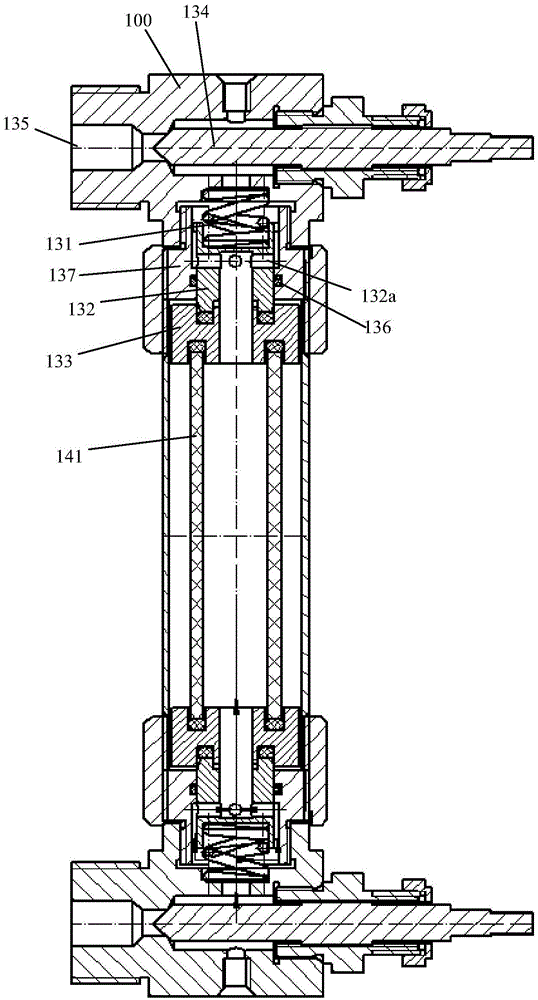

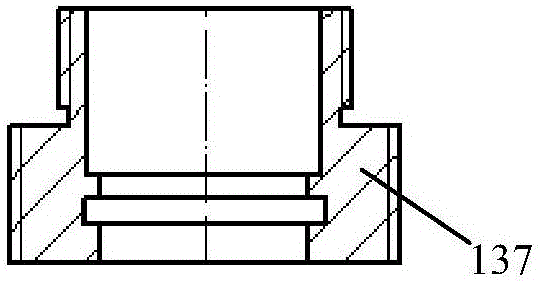

[0018] As shown in the figure, this embodiment provides a self-closing liquid level observer with adjustable center distance, including two sets of upper and lower valve body assemblies 103 and a sheath tube assembly 104 in the middle; the valve body assembly 103 includes a valve body 100, the main valve core 134 located in the valve body 100, the self-closing valve core 132, the self-closing valve sleeve 137, the spring 131 and the pressure sleeve 133, the self-closing valve core 132 is located in the self-closing valve sleeve 137 and It can move in the self-closing valve sleeve 137; among the two groups of valve body assemblies 103, the self-closing valve sleeve 137 of at least one group of valve body assemblies 103 is screwed on the valve body 100, the The side of the self-closing valve sleeve 137 close to the valve body 100 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com