A lvdt sensor installation structure for an actuator

An installation structure and sensor technology, applied in the direction of using electrical devices, instruments, measuring devices, etc., can solve problems such as low reliability, jumping electromechanical actuators, external media interference, etc., to improve accuracy and reliability, and improve installation Strength, the effect of realizing redundancy configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

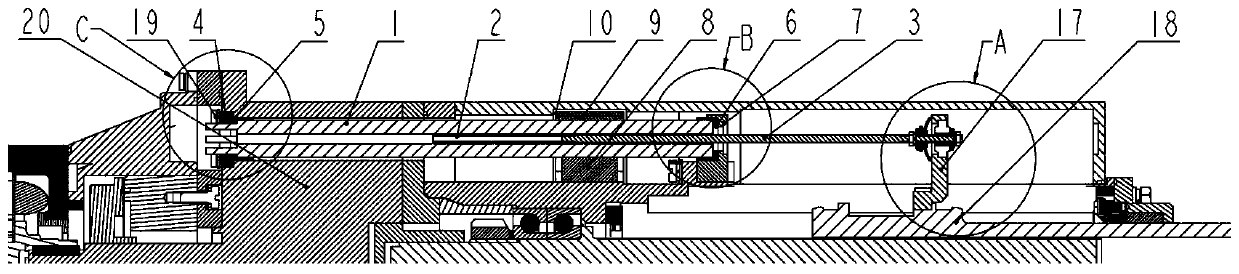

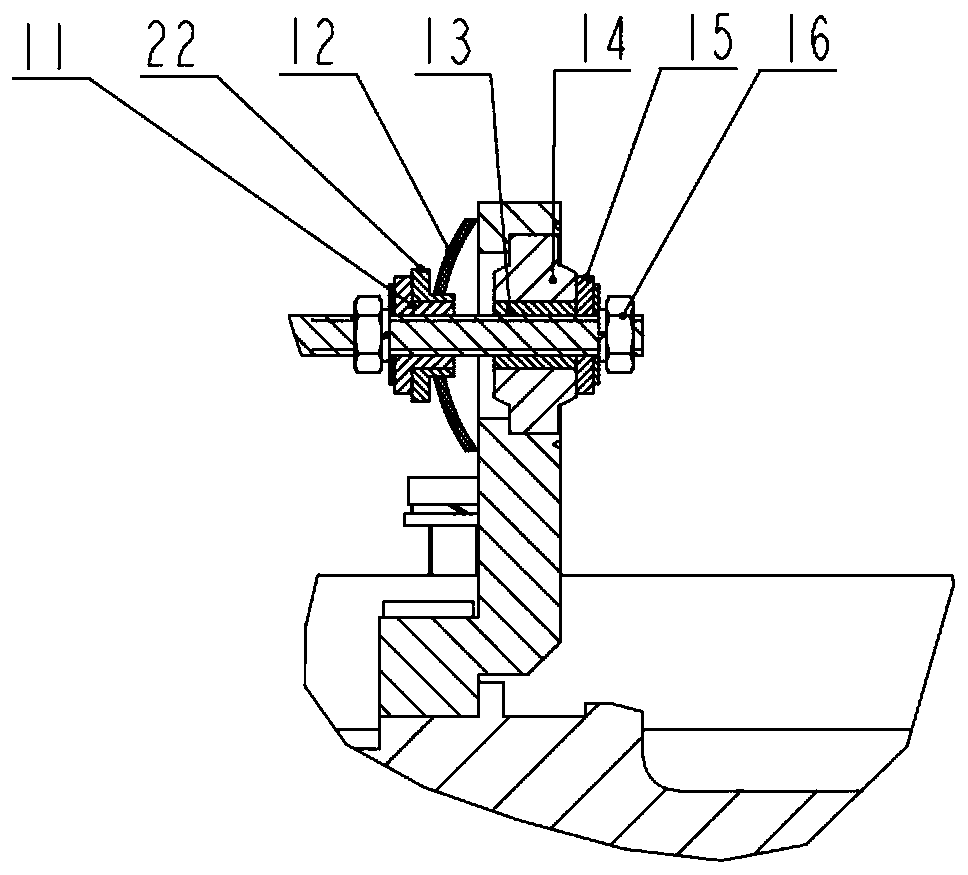

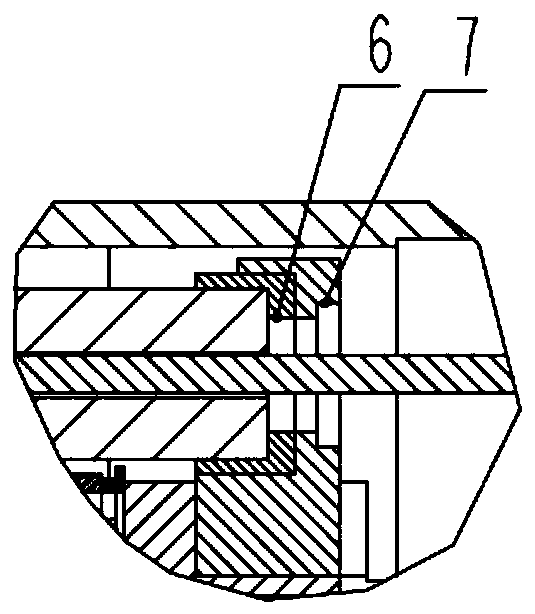

[0032] The LVDT sensor is a differential transformer displacement sensor, such as figure 1 with Figure 5 As shown, two sets of LVDT sensor installation structures for an actuator according to the present invention are installed side by side inside the actuator. The iron core connecting rod 3 of the LVDT sensor is fixedly connected with the ball screw nut 18 of the actuator, which can directly measure the linear output position of the actuator; interference problem.

[0033] A LVDT sensor installation structure for an actuator of the present invention includes a first connection assembly, a second connection assembly, a flexible structure assembly, a support assembly, an iron core connecting rod 3, and an insulation assembly;

[0034] The outlet end of the LVDT sensor stator 1 is fixed on the reducer housing 20 of the actuator through the first connection assembly, the outlet end is the first end of the LVDT sensor stator 1, and the other end is the second end; the LVDT sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com