Transverse location structure used for S-shaped tube panel

A technology of lateral positioning and serpentine tube, applied in the direction of boiler support/positioning device, etc., can solve the problems of large damage to the tube 8, deformation of the tube 8, tube burst accident, etc., and achieve the effect of not easy to fall, convenient welding, and good strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

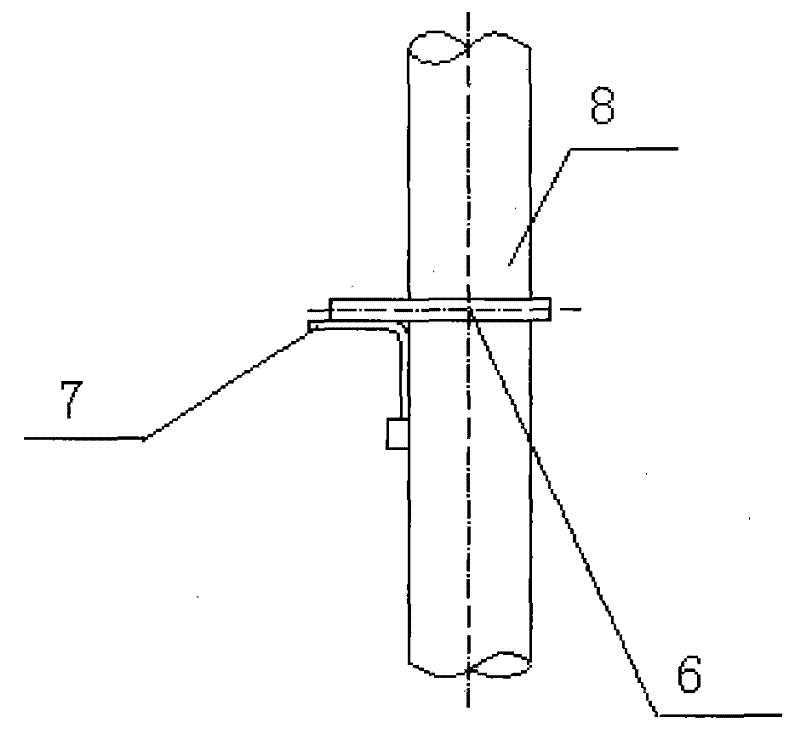

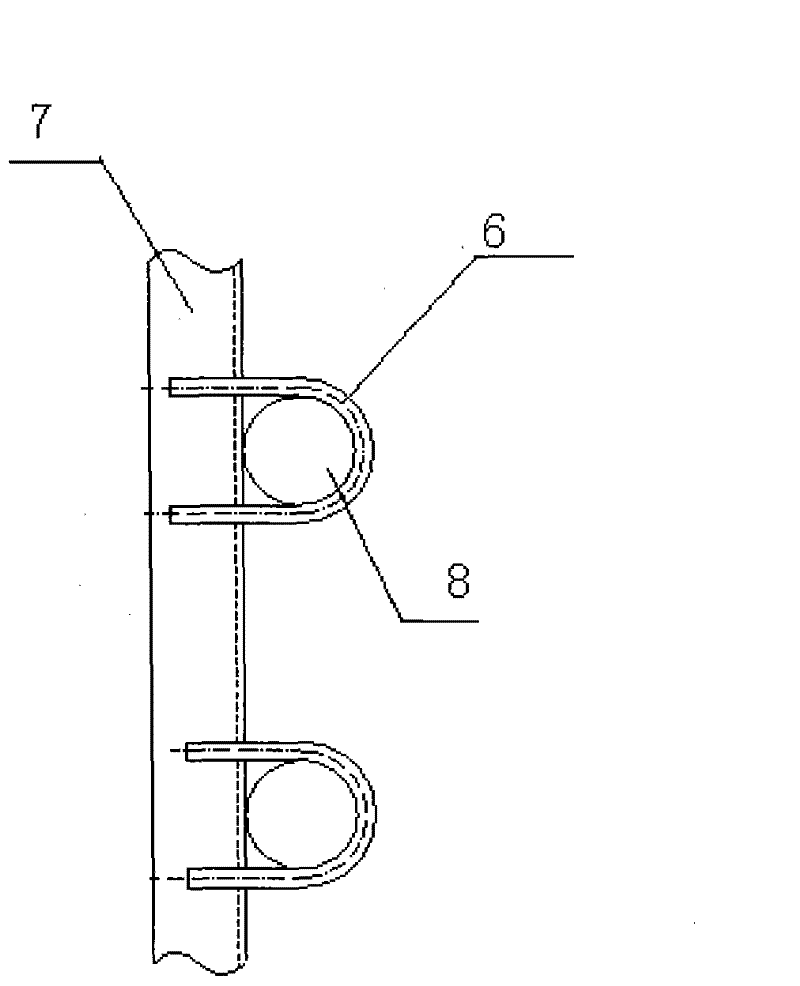

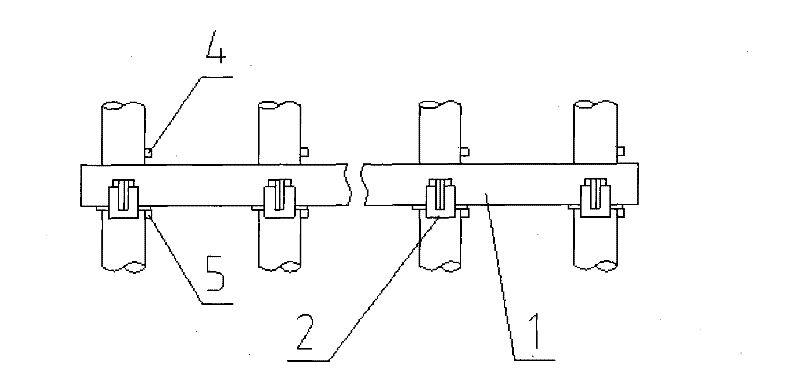

[0015] Such as Figure 3 to Figure 5 As shown, the present invention provides a lateral positioning structure for a serpentine tube panel, a tube clip 3 is placed over each tube 8 forming the tube panel, and the first steel plate 1 with a groove at the bottom is embedded in all tube panels. Above the end of the clamp 3, a small steel block 2 is embedded below the end of each pipe clamp 3, and a first positioning steel block 4 and a second positioning steel block 4 are respectively arranged above and below each pipe 8 above and below the pipe clamp 3. Position steel block 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com