A smart combustion control method for thermal power plants based on cloud data and cloud computing

A thermal power plant, cloud computing technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve the problems of boiler combustion modeling and optimization difficulties, model mismatch, etc., to reduce hardware equipment requirements and investment costs , lower requirements, and strong generalization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings.

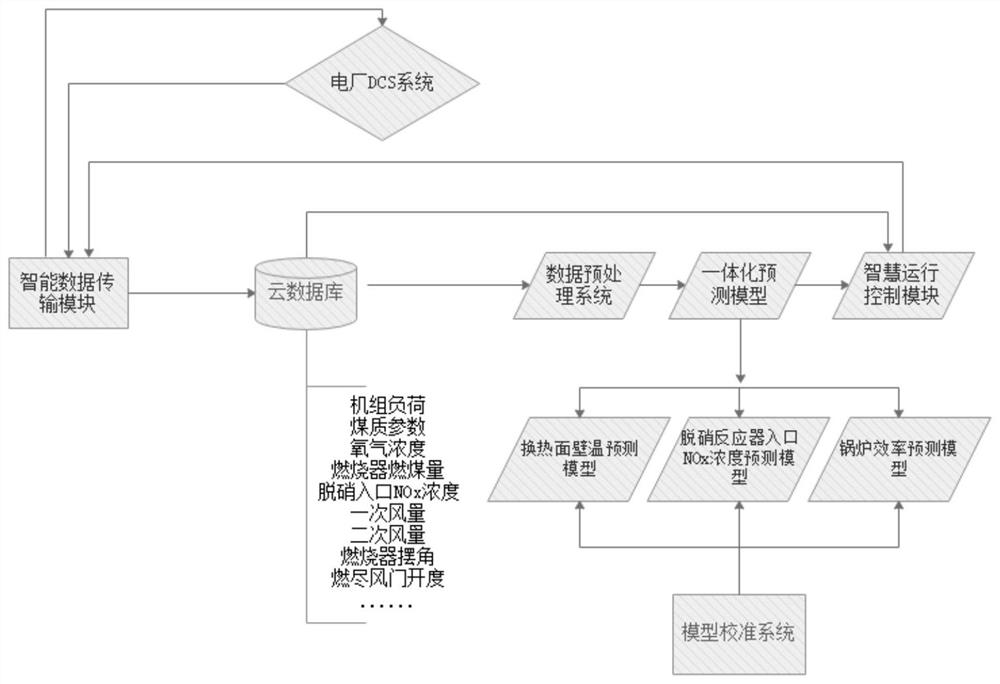

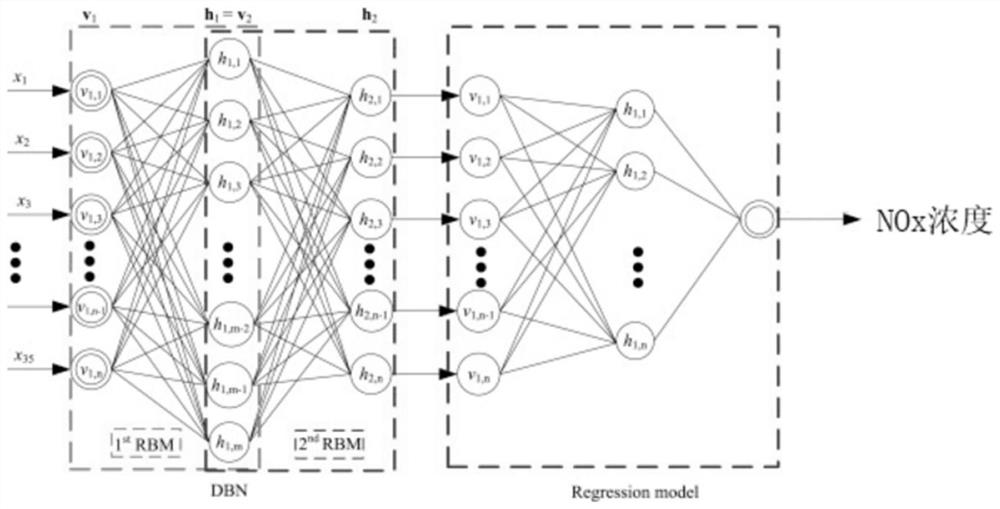

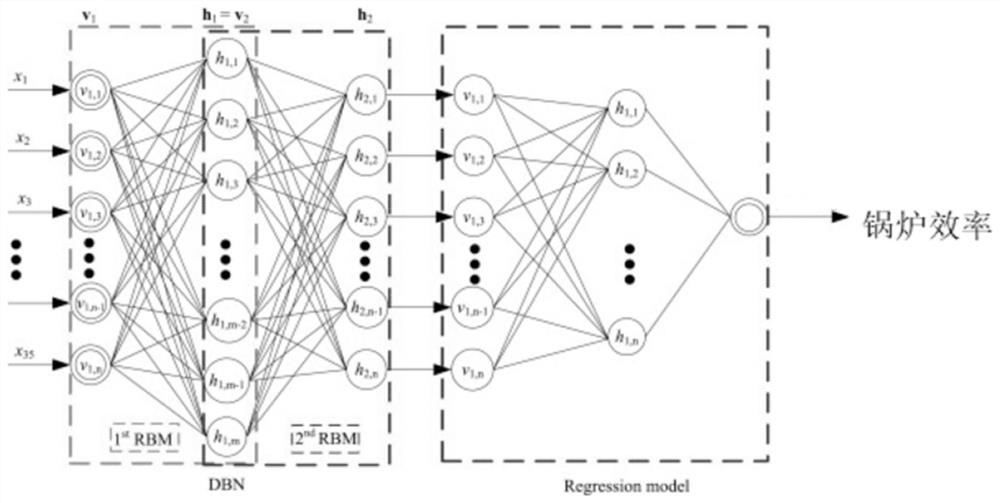

[0036] see figure 1 , figure 2 , image 3 and Figure 4 , a method for intelligent combustion control of thermal power plants based on cloud data and cloud computing, the steps are as follows:

[0037] S1: Build a cloud database. The cloud database is divided into a benchmark database and an original database; the original database automatically collects the DCS data of thermal power plants and divides them into input data and output data; Feed water volume, feed water temperature, superheated steam temperature, reheat steam temperature, reheat steam pressure, coal quality parameters, primary air volume, secondary air volume, oxygen concentration, combustion temperature, primary air temperature, secondary air temperature, burner swing angle , fuel air door opening, secondary air door opening, burnout air door opening and heat exchange surface wall temperature, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com