Sliding type air bag plug plate system for tunnel lining trolley

A technology for lining trolleys and plug plates, which is applied in tunnel lining, tunnel, shaft lining, etc., can solve the problems such as the installation quality of waterstops and the difficulty of sealing and fitting the plug plates, achieve flexible and diverse working conditions, and improve construction Efficiency, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

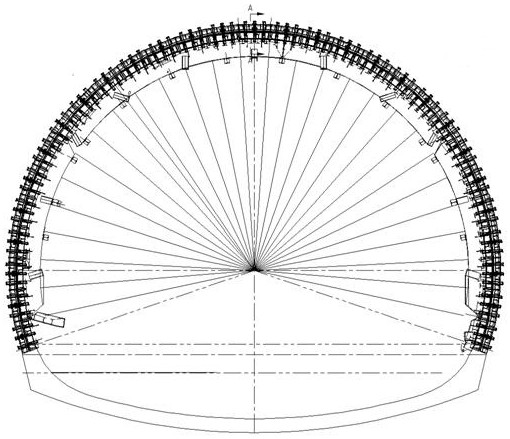

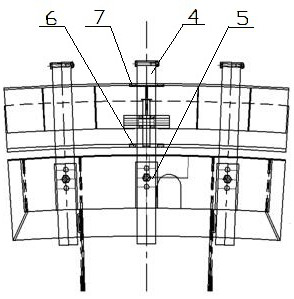

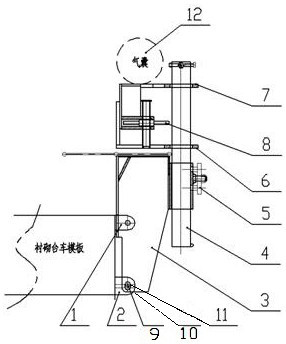

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] As shown in the figure, a sliding type airbag plug plate system for tunnel lining trolleys, including the first ear plate 1 of the trolley formwork, the second ear plate 2 of the trolley formwork, the base of the plug plate 3, and the sliding square tube Shaft 4, pressure plate assembly 5, lower slide plate 6, upper slide plate 7, lifting adjustment mechanism 8, bolt assembly and air bag 12, the plug plate base 3 includes an inner plate 301, an outer plate 302, a top plate 303, a connecting plate 304, a side Plate 305, support plate 306, outer square pipe 307, hexagonal bolt 308 and hexagonal nut 309, wherein inner plate 301, outer plate 302, top plate 303, connecting plate 304 and side plate 305 surround the cylindrical mechanism with opening downward, supporting The two ends of the plate 306 are respectively wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com