A Lifting Mechanism for Realizing Vertical Lifting and Horizontal Elasticity of Furnace Door

A vertical lifting and furnace door technology, which is applied in the direction of furnaces, heat treatment furnaces, furnace components, etc., can solve the problems of equipment costs, use costs that cannot meet energy saving and consumption reduction, cannot meet the requirements of furnace mouth sealing, and furnace doors are not vertically lifted, etc. To achieve the effect of reliable performance, novel design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

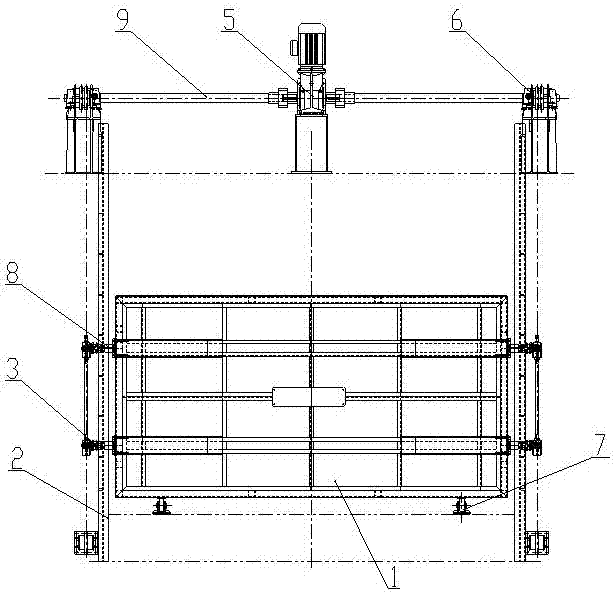

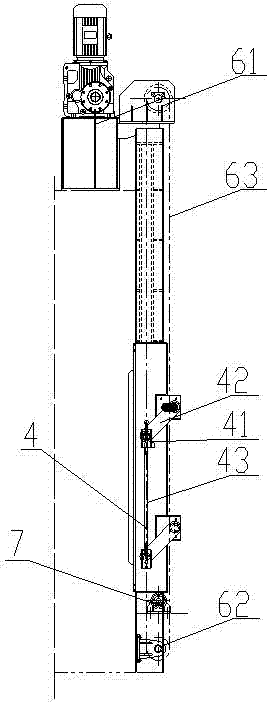

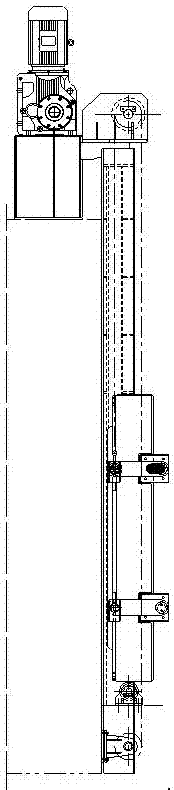

[0016] This embodiment is a lifting mechanism that realizes the vertical lifting and horizontal tightening of the furnace door. The structure is as follows: Figure 1-3 As shown, it includes furnace door 1, guide rail 2, guide wheel 3, parallelogram mechanism 4, drive mechanism 5, chain transmission device 6 and support wheel 7, and the drive mechanism is a double-axis reducer driven by a motor; parallelogram mechanism 4 includes Limit seat 41, connecting plate 42 and a synchronous connecting rod 43, limit seat 41 is provided with the rotating shaft that is connected with connecting plate, the limit seat top is opening structure, is provided with for connecting plate and is horizontal at the limit seat bottom. The two ends of the synchronous connecting rod are each equipped with a limiting seat, which is connected to one end of the connecting plate through the limiting seat, and the other end of the connecting plate is connected to the rotary shaft of the furnace door in rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com