Large-volume sample loading device

A large-volume, sample bottle technology, applied in the direction of analysis materials, instruments, etc., can solve the problems of large errors and poor sealing, and achieve the effects of avoiding sample loading errors, increasing the volume of the column, and improving the efficiency of sample loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

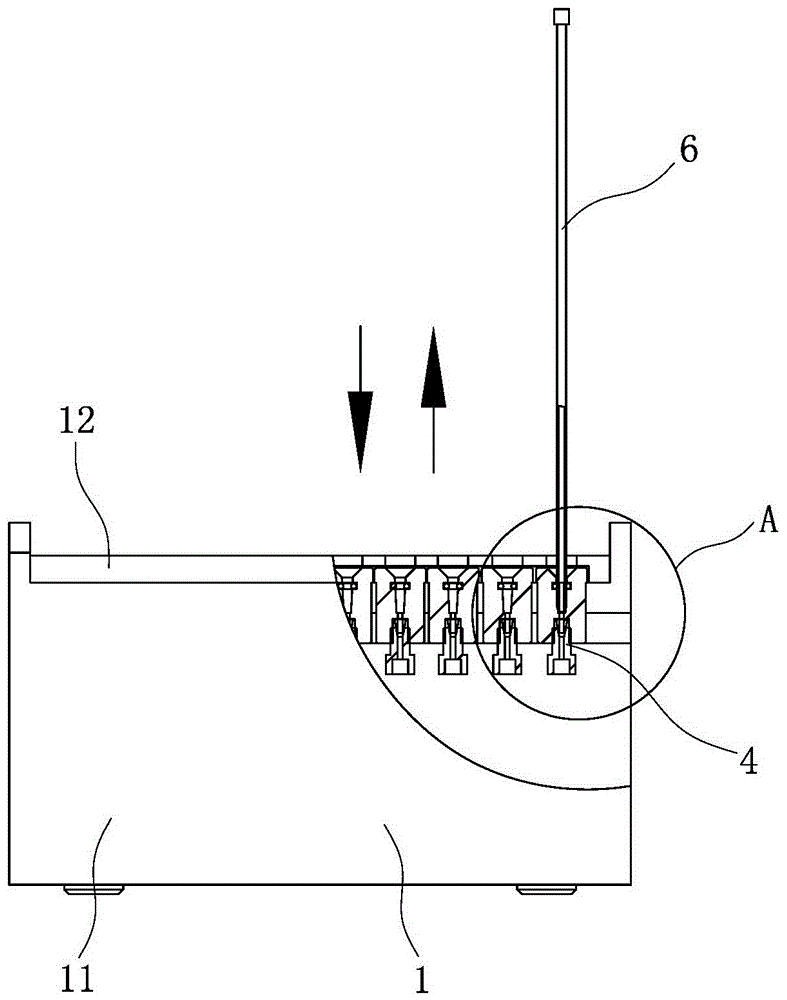

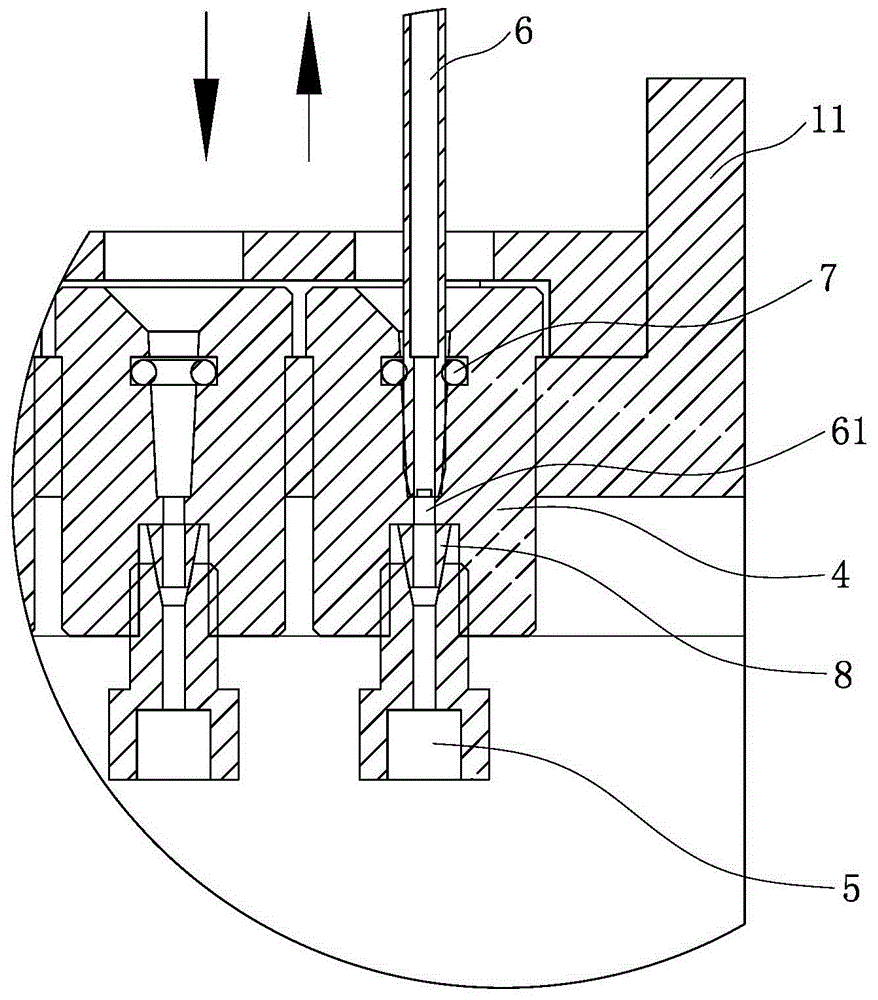

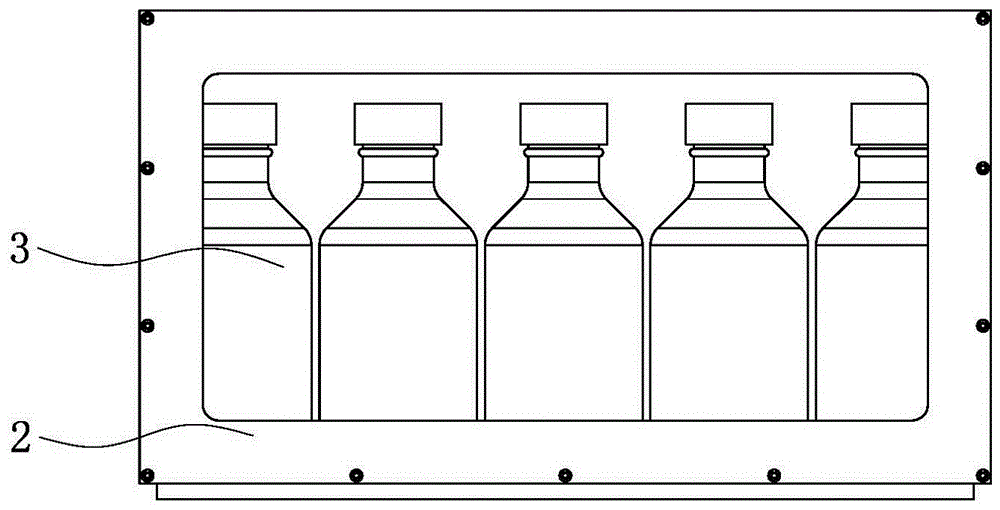

[0022] Such as figure 1 and 5 As shown, the large-volume sample loading device disclosed in the present invention includes a sample loading rack 1, a sample loading bottle box 2, a 1L sample loading bottle 3, a sleeve body 4, a joint 5 and a sample loading needle 6;

[0023] The upper end of the sleeve body 4 forms an upper socket 41 for inserting the sample needle 6, and the lower end of the sleeve body 4 opens a lower threaded hole 42 for the joint 5 to be screwed and locked. The connecting hole 43 through which the needle head 61 of the sample loading needle passes, 20 sleeve bodies 4 are installed on the top of the sample rack, and a joint 5 is inserted on each sleeve body 4;

[0024] 20 1L sample bottles 3 are set in the sample bottle box 2 corresponding to the 20-position sleeve bodies, and the 20-position sample bottles 3 are connected to the 20-position sleeve bodies 4 one by one through the joint 5. Specifically, the joint 5 and the 1L sample loading A Teflon thin h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com