flow switching valve

A flow path switching and valve seat technology, applied in multi-port valves, valve devices, valve details, etc., can solve the problems of easy wear of sliding parts, increased pressure loss, deterioration of sealing performance, etc. Pressure, the effect of reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

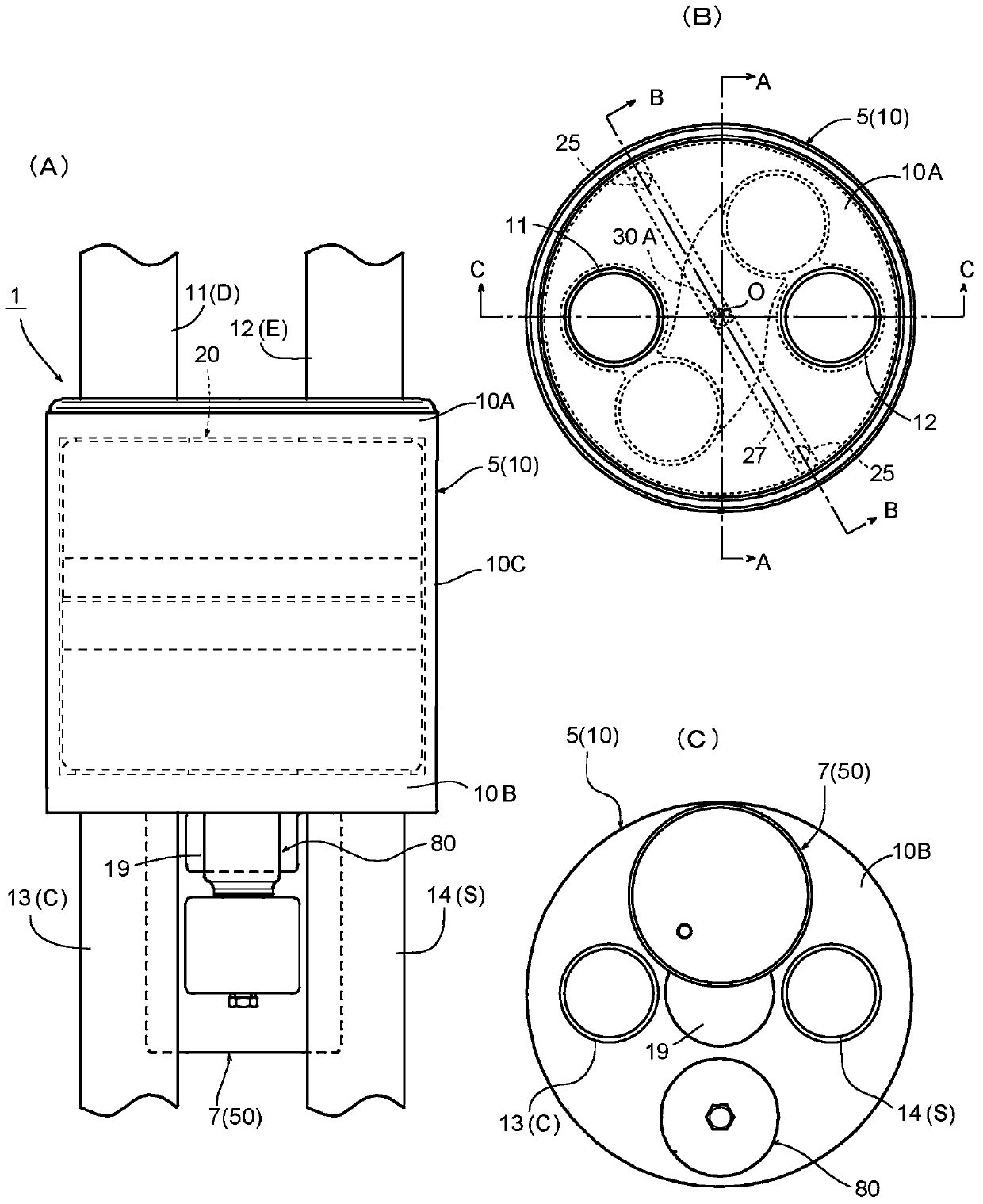

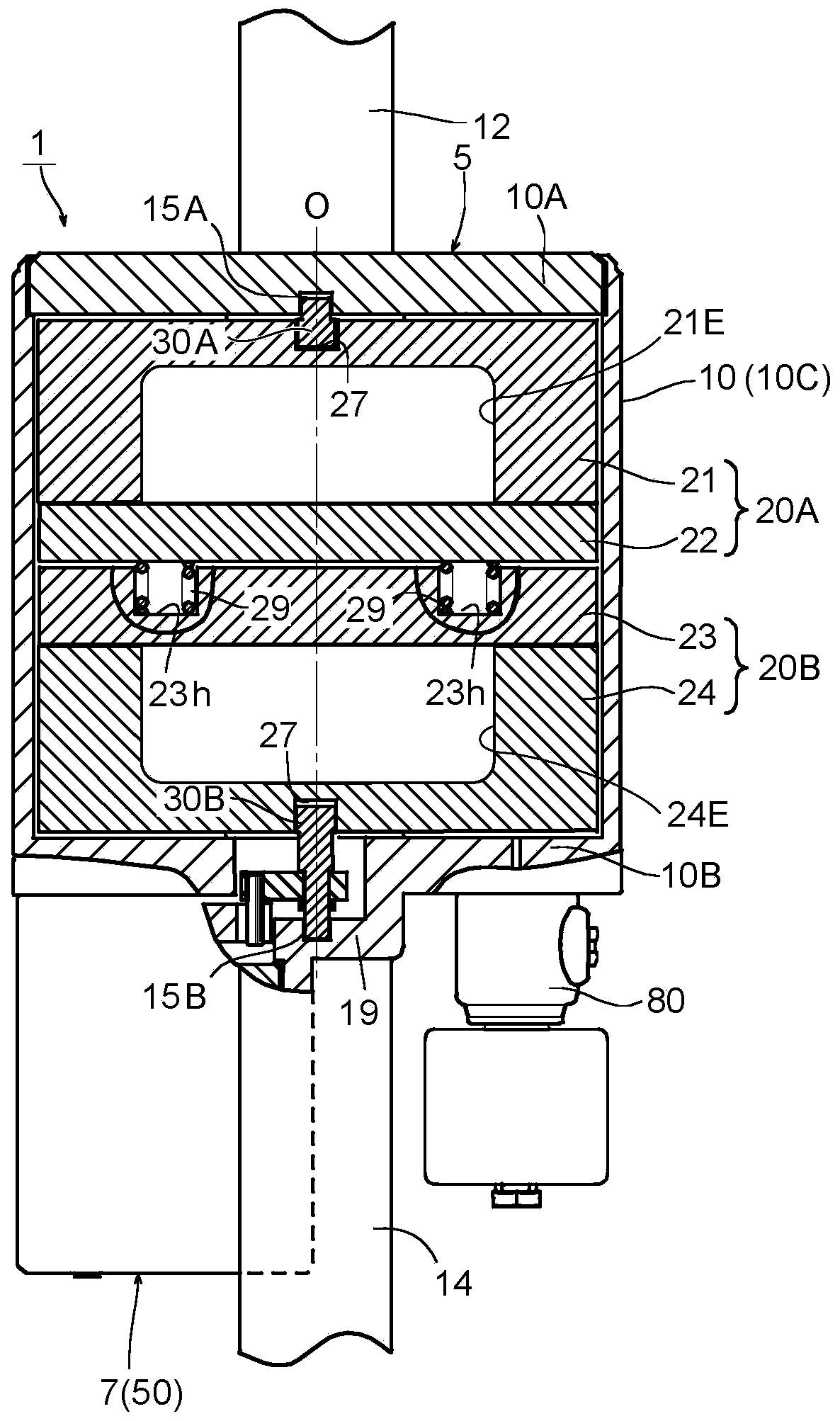

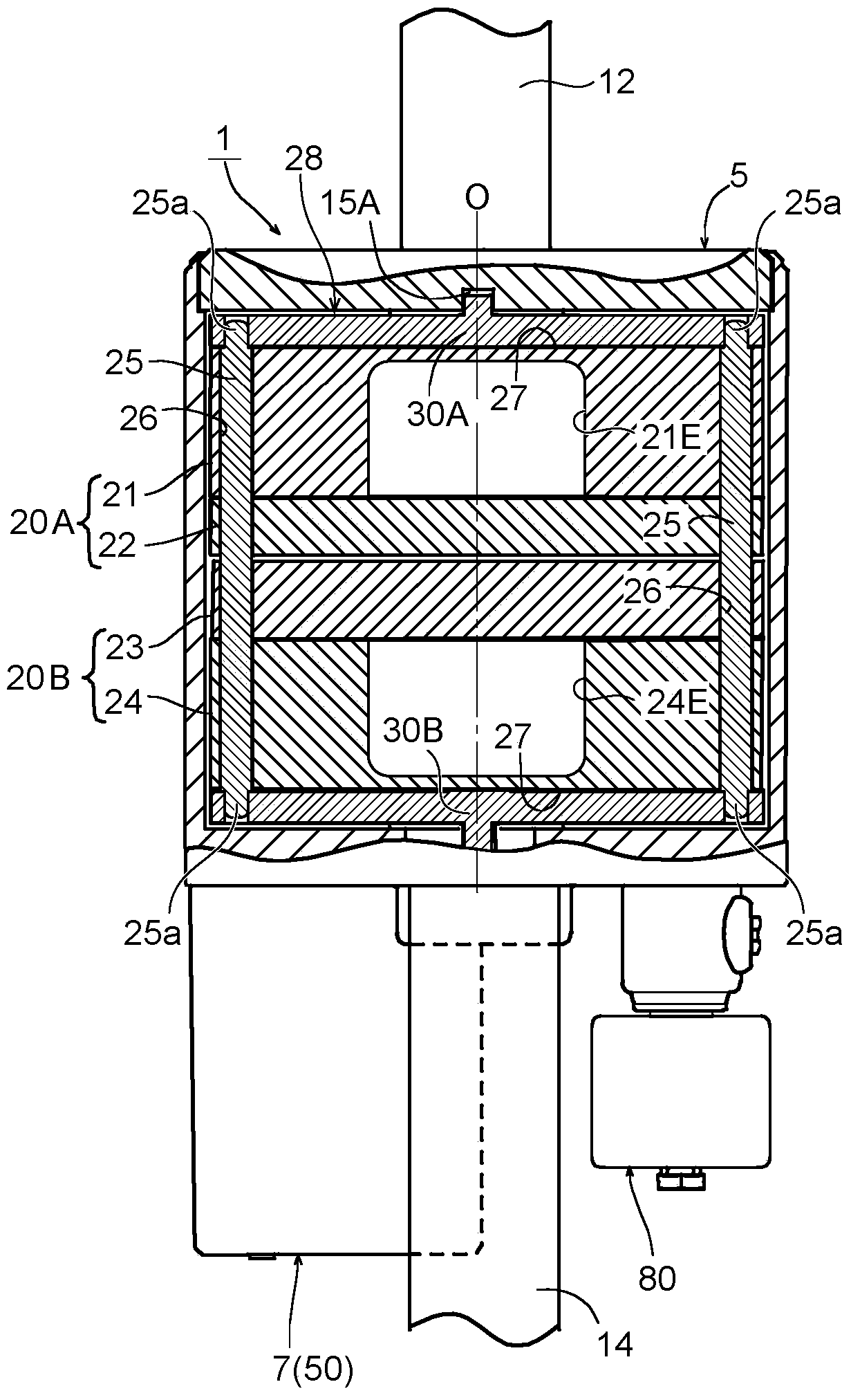

[0062] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings.

[0063] figure 1 The first embodiment of the channel switching valve according to the present invention is shown, (A) is a side view, (B) is an upper surface side configuration diagram, and (C) is a lower surface side configuration diagram. in addition, figure 2 , image 3 , Figure 4 respectively figure 1 In (B), another side view of the partial fracture along the line A-A, another side view of the partial fracture along the line B-B, and an enlarged cross-sectional view of the main valve part along the line C-C.

[0064] In addition, in this specification, the expression of positions and directions such as up and down, left and right, front and rear are added for the convenience of the drawings in order to avoid cumbersome description, and do not limit the positions and directions in the state of actual assembly in the heat pump cooling and heating syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com