Flip direct falling type optical chip module testing socket

A technology for testing optical chips and modules, which is applied in the direction of measuring devices, measuring electrical variables, and measuring device casings, and can solve problems affecting the position of the chip lens hole, chip shift, and affecting the test results of high-pixel optical chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

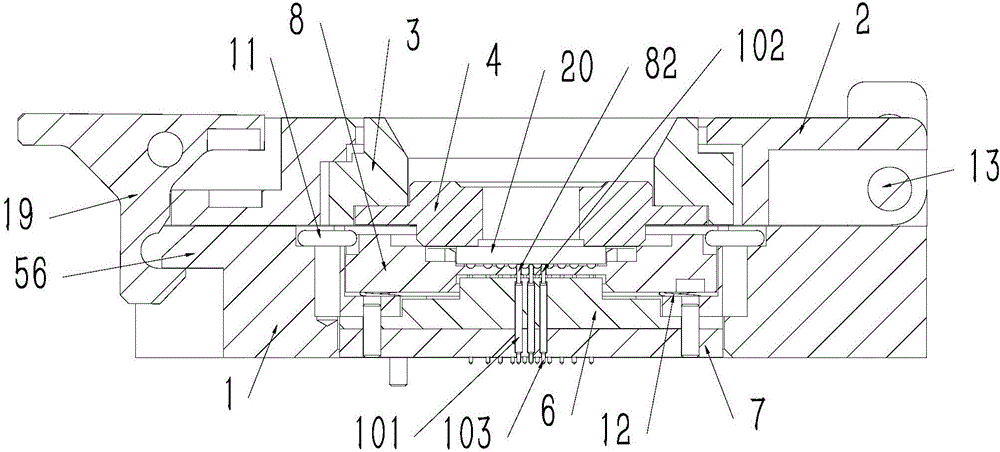

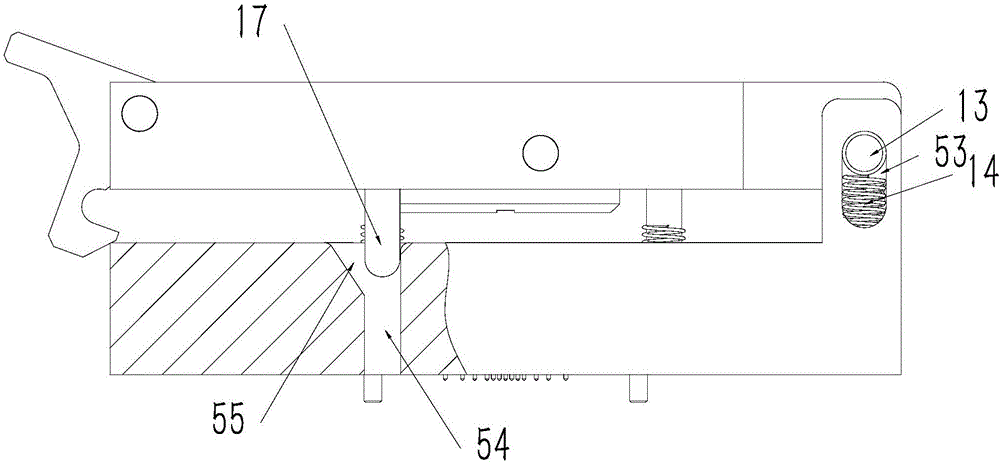

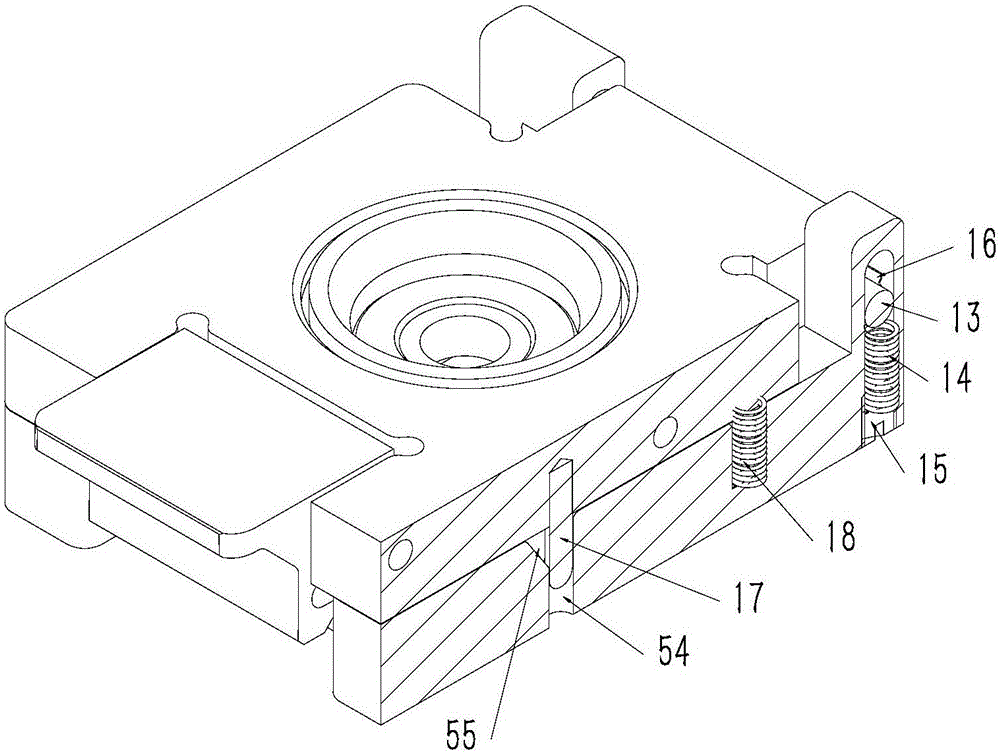

[0023] see figure 1 , 2 , The flip-down type manual optical chip module test socket shown in 5 mainly includes a base 1, an upper cover 2 flipped and connected to the base, a screw cover 3, a pressure plate 4, a main board 6, a retaining plate 7, a floating plate 8, Probe 10.

[0024] The probe 10 belongs to the prior art, and includes a needle bar 101 and an upper needle head 102 and a lower needle head 103 floatingly connecting the two ends of the needle bar.

[0025] A base hole 52 with a step 51 is formed on the base 1. The main board 6 is fixed at the bottom of the base hole 52, and the holding plate 7 is fixed on the base below the main board. There is a floating plate 8 in the top of the base hole 52 . The periphery of the bottom of the floating plate 8 is arranged on the upper part of the step 51 floating up and down through four floating springs 12. The floating plate is located above the main board. There is a chip slot 81 for placing the optical chip module 20 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com