A permanent magnet motor rotor and generator

A permanent magnet motor and rotor technology, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of complicated rotor assembly and easy demagnetization, and achieves easy promotion, simple installation process and good use effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

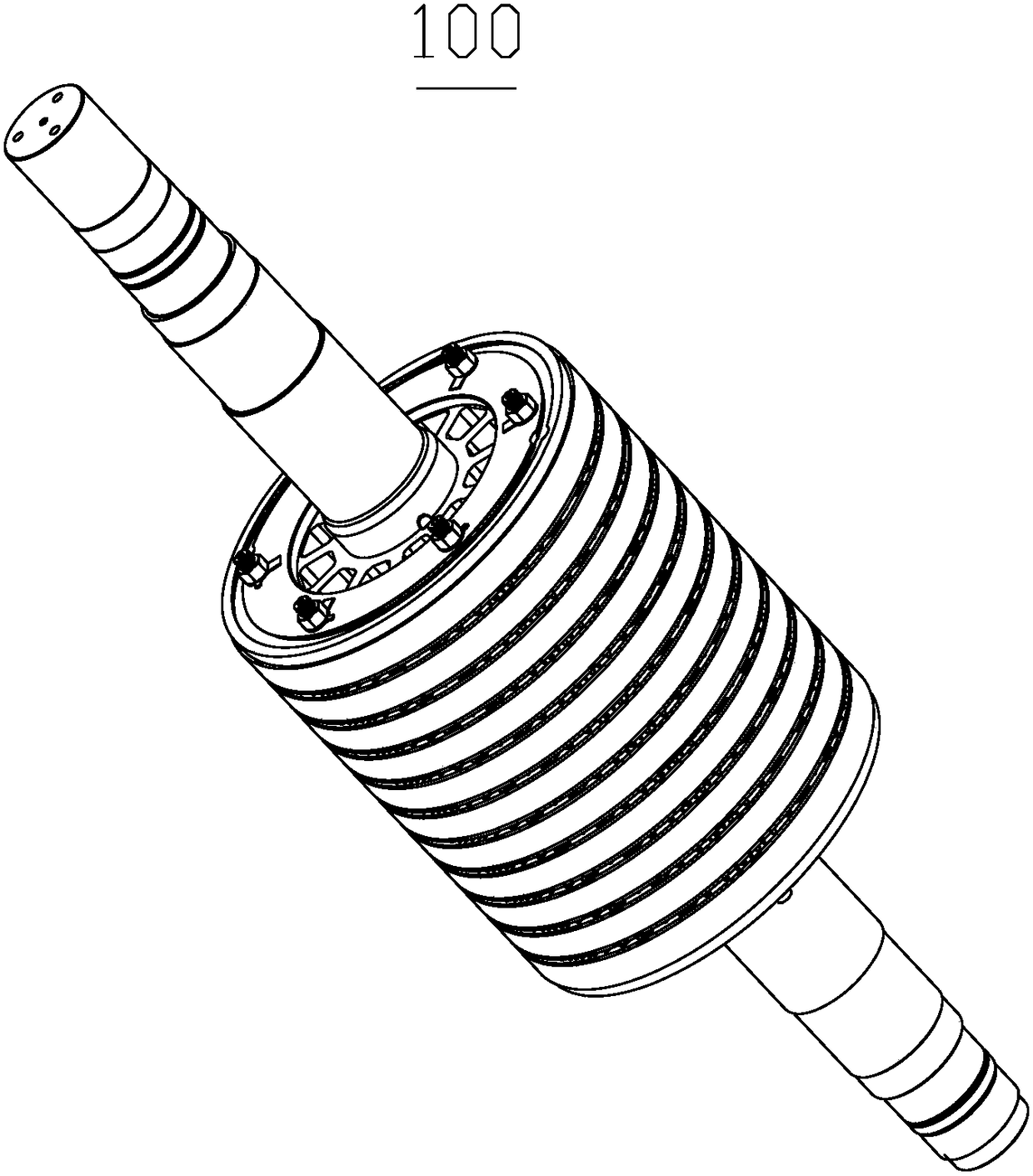

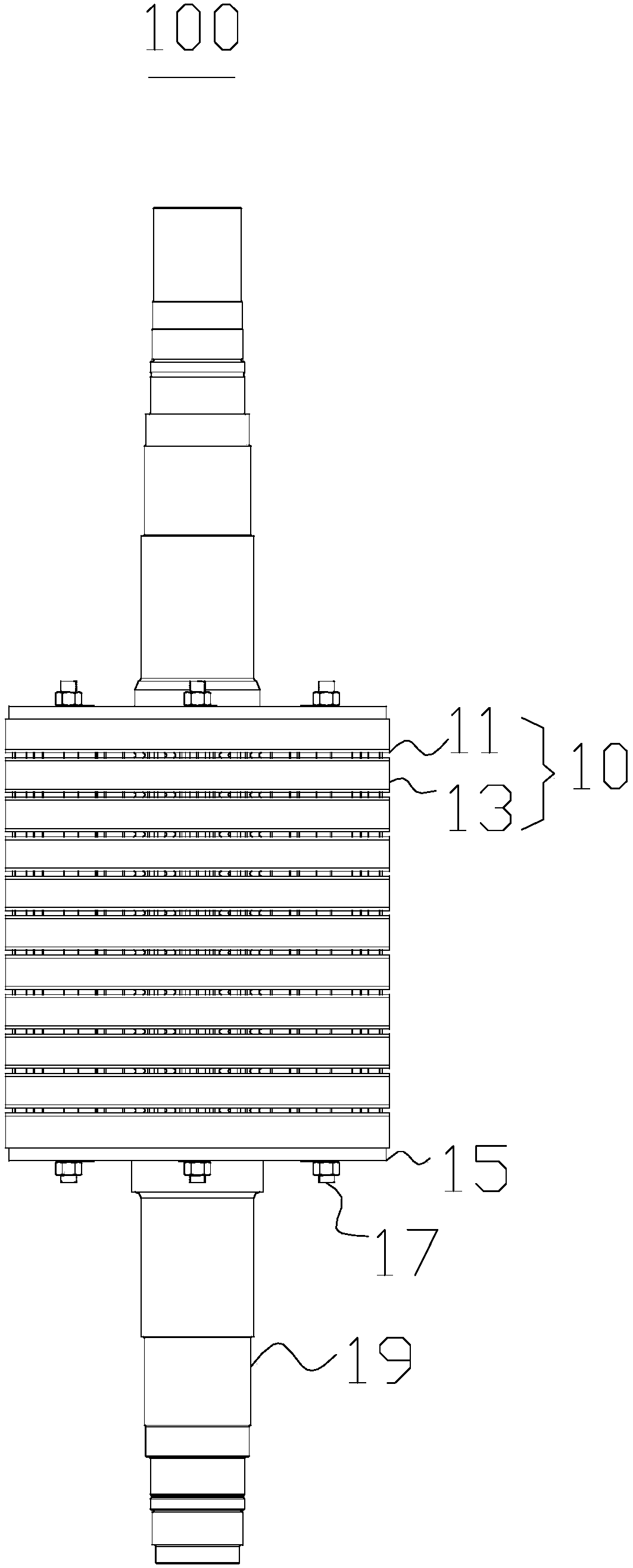

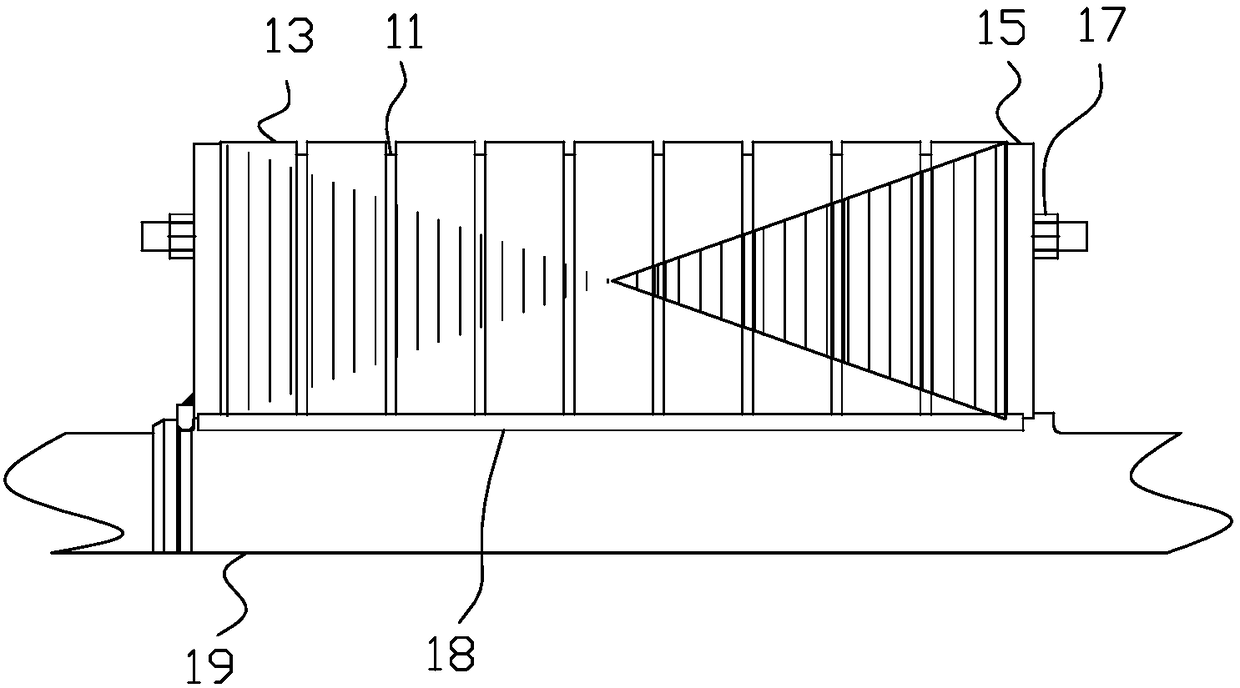

[0046] Please refer to figure 1 with figure 2 , this embodiment provides a permanent magnet motor rotor 100, including a rotor core 10, a pressure plate 15 and tension bolts 17, the rotor core 10 is formed by stacking a plurality of rotor punches 13 and a plurality of ventilation slot plates 11.

[0047] Two adjacent rotor punches 13 are separated by a ventilation slot plate 11, the ventilation slot plate 11 includes at least two ventilation slots and a plurality of spacer bars, the spacer bars are located between the two ventilation slots and surround the rotor core. The axis of 10 is distributed in a ring, the length direction of the spacer is arranged along the radial direction of the rotor core 10 and a plurality of radial ventilation passages are formed between two adjacent ventilation slots, and the pressure plates 15 are located at both ends of the rotor core 10 and Tighten by tensioning bolt 17.

[0048] Specifically, the rotor punch 13 is formed by stacking a plura...

Embodiment 2

[0084]This embodiment also provides a generator, which includes the permanent magnet motor rotor 100 mentioned above, the structure of the permanent magnet motor rotor 100 can refer to embodiment 1, the generator has all the functions of the permanent magnet motor rotor 100 .

[0085] When the generator with the permanent magnet motor rotor 100 is in working state, the magnet steel 137 has a better heat dissipation effect, and the magnet steel 137 is not easy to demagnetize.

[0086] To sum up, the present invention provides a permanent magnet motor rotor 100. By setting radial ventilation passages, the air in the rotor core 10 can achieve a better flow, and the flowing air takes away the heat on the magnetic steel 137. The exchange with the external air reduces the temperature of the magnetic steel 137, ensuring that the magnetic steel 137 will not be demagnetized due to overheating even if it works for a long time. Through the cooperation of the ventilation slot plate 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com