Method for testing brake systems of motor vehicles

A technology for braking systems and motor vehicles, applied in the direction of braking safety systems, etc., can solve problems such as wrong evaluation and wrong judgment, and achieve the effect of improving the accuracy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

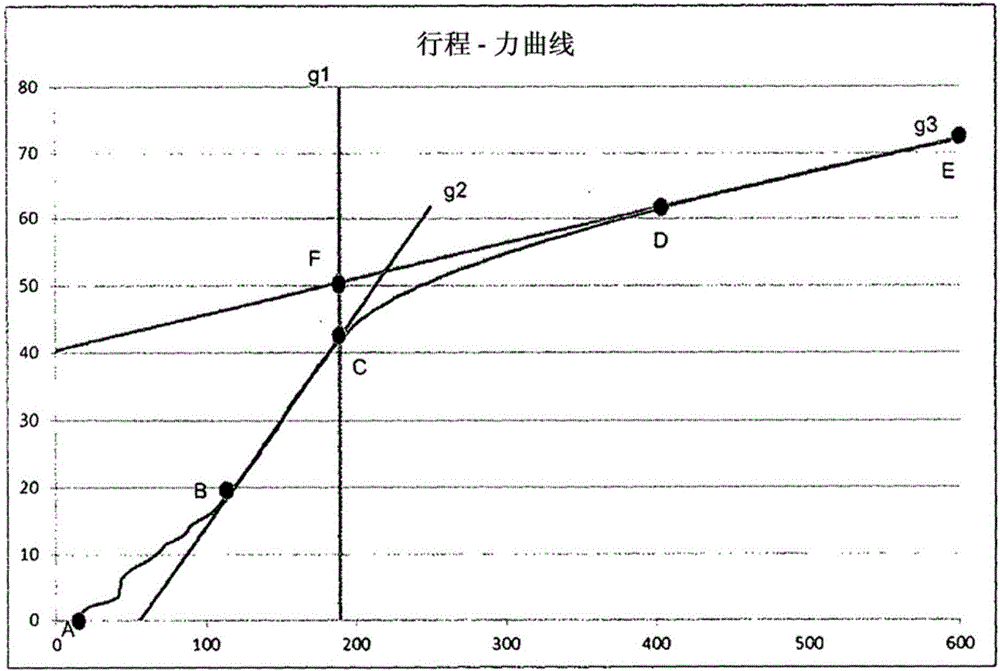

[0017] In the area of the curve between points A and B, only parts of the pedal mechanism including the brake booster move, but without a reinforcing effect.

[0018] In the curve region between points B and C, the brake master cylinder begins to move. Here, the brake linings are not yet in contact so that no appreciable hydraulic pressure can develop. The movement is approximately linear. However, movement of the seal can be seen in this region. As long as enough measuring points are found in this linear relationship, the area can be described by the straight line "g2". The reference of this measuring point is a determined correlation.

[0019] In a further extension, the travel-force curve transitions into a curved region. The fixed point C is determined by the start of a pronounced bending of the travel-force curve in the direction of the point D. FIG. Point C is where the hydraulic pressure rises significantly on the curve. The straight line "g1" extending vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com