Optical components and surface light source devices

An optical element, surface light source technology, applied in optical elements, plane light source, optics, etc., can solve the problem of too dark around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

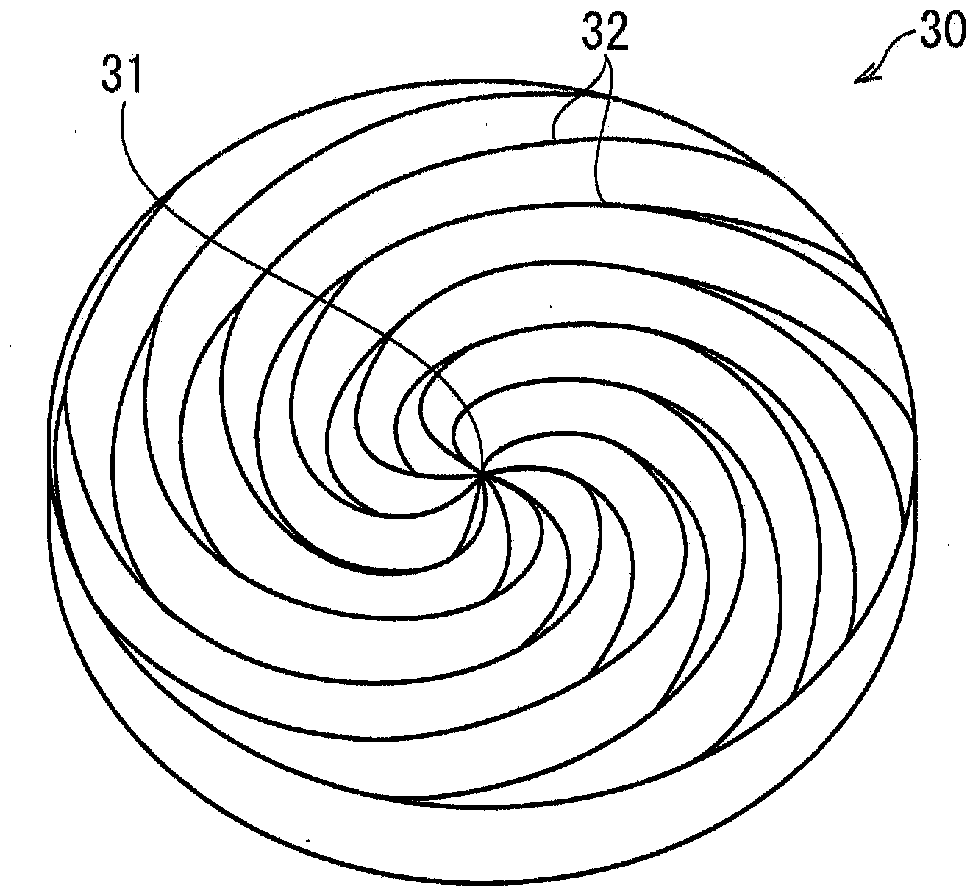

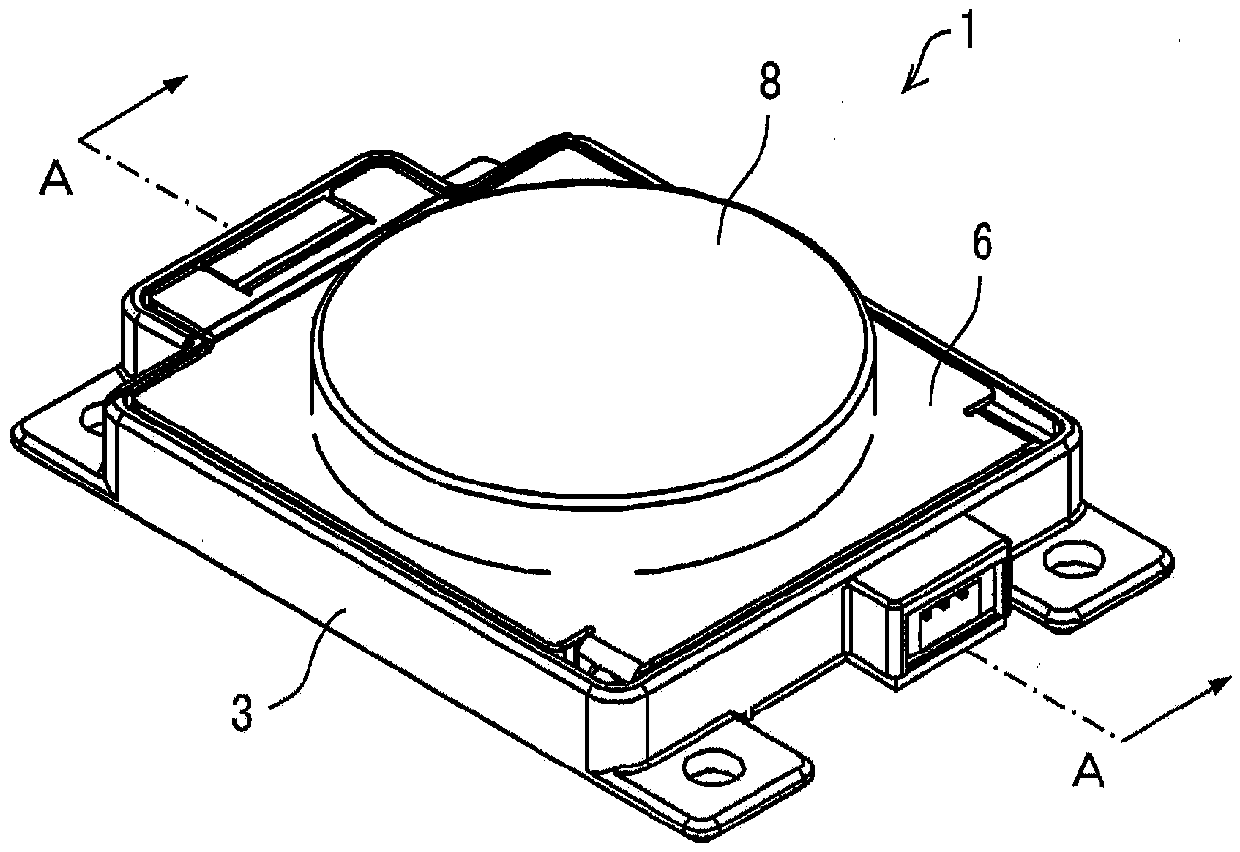

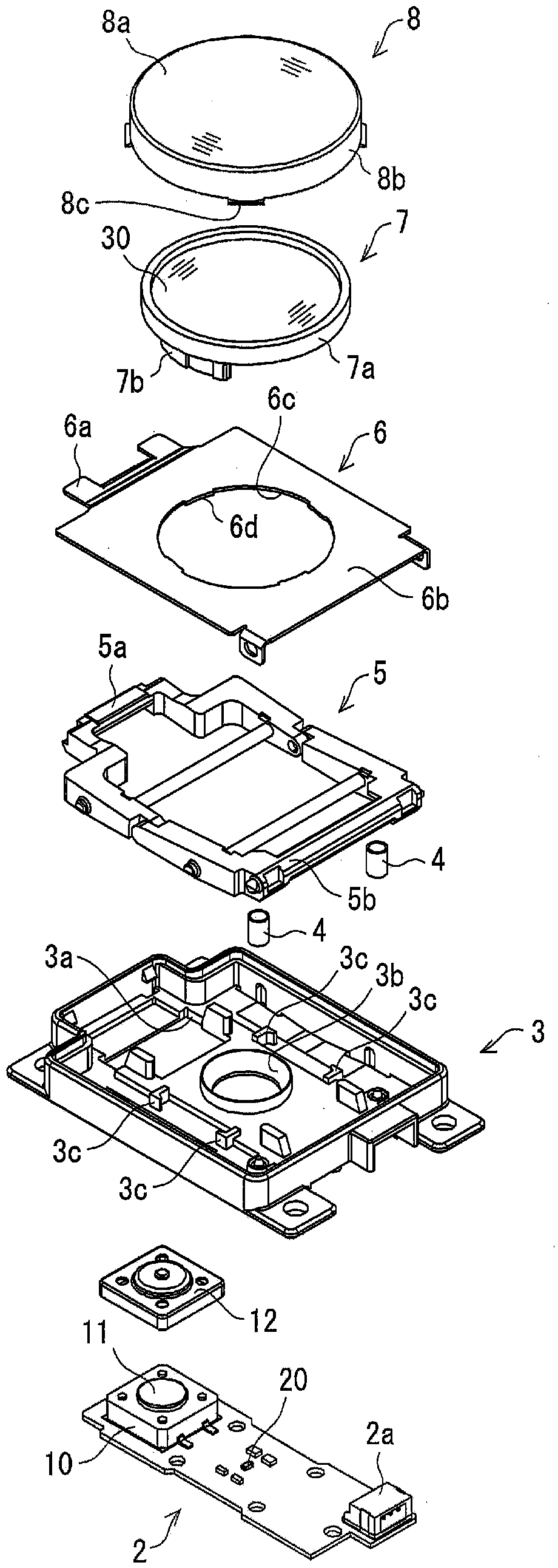

[0047] Below, according to Figure 1 to Figure 9 One embodiment of the present invention will be described.

[0048] An application example of applying the optical element and the surface light source device of this embodiment to an illuminated push button switch is described, wherein the illuminated push button switch is used, for example, as a switch installed on a wall surface of an elevator hall The indicator switch for the up or down direction set in the operation panel of the elevator on the elevator; or the indicator switch installed in the elevator to indicate door opening, door closing and floor number, etc. Moreover, the optical element and the surface light source device of the present invention are not limited to the application of the illuminated pushbutton switch, and can also be applied to other fields.

[0049] according to Figure 2 ~ Figure 4 , the configuration of the illuminated push button switch 1 including the optical element and the surface light sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com