Potato harvester

A potato and harvester technology, which is applied to digging harvesters, harvesters, excavators, etc., can solve the problems of easy damage to the skin of potatoes, good potato-soil separation effect, and insufficient potato-soil separation, etc., to reduce the self-weight , Good potato-soil separation effect, convenient layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

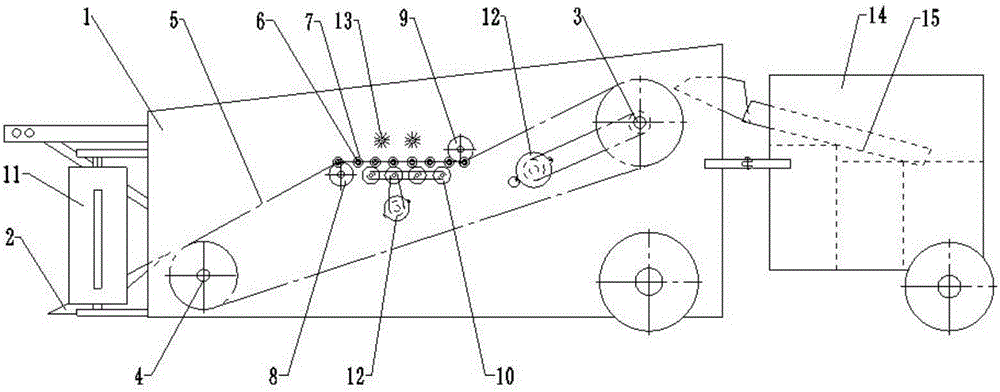

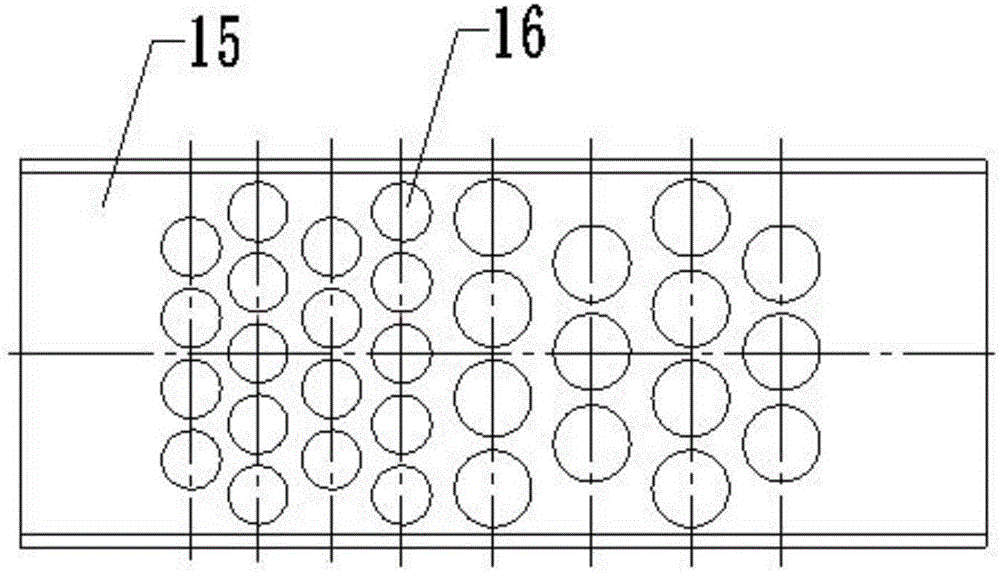

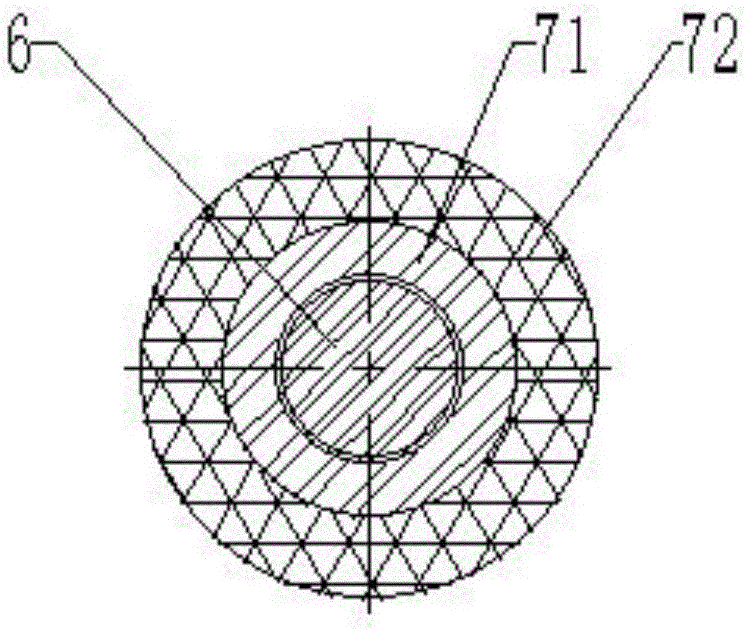

[0019] Such as Figure 1-3 As shown, a single ridge and double-row potato planter in this embodiment includes a frame 1, a digging shovel 2 at the front of the frame, a potato soil conveying device and a transmission device for driving the potato soil conveying device. The soil conveying device comprises a driving shaft 3, a driven shaft 4, and a conveying chain 5 installed on both sides of the driving shaft 3 and the driven shaft 4. The conveying chain 5 is evenly fixed with a conveying rod 6, and the conveying rod 6 is Cylindrical, and equipped with a circular tube-shaped delivery rod jacket 7; the delivery chain 5 is equipped with a tension roller 8 and a pinch roller 9 in the transmission direction, and the transmission between the tension roller 8 and the pinch roller 9 The chain is transmitted horizontally; a driving roller 10 is also provided between the tension roller 8 and the pressing roller 9, and the driving roller 10 frictionally drives the outer casing 7 of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com