Multimode rice milling and pulverizing combination machine

A combined machine, multi-mode technology, applied in applications, grain processing, agriculture, etc., can solve problems such as inconvenience and flexibility in use, inability to achieve integrated processing, and inability to meet production and living needs, and achieve the effect of strong technical popularization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The specific implementation, structure, features and functions of the beverage bottle cap proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

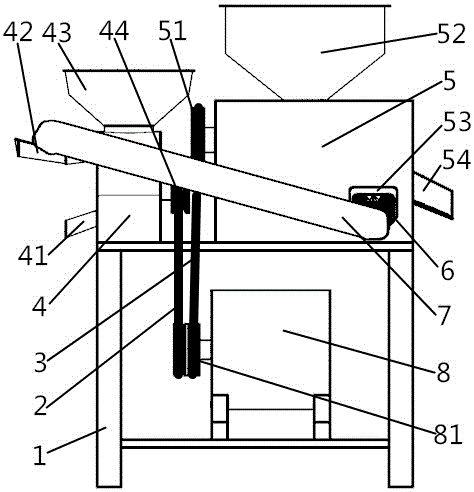

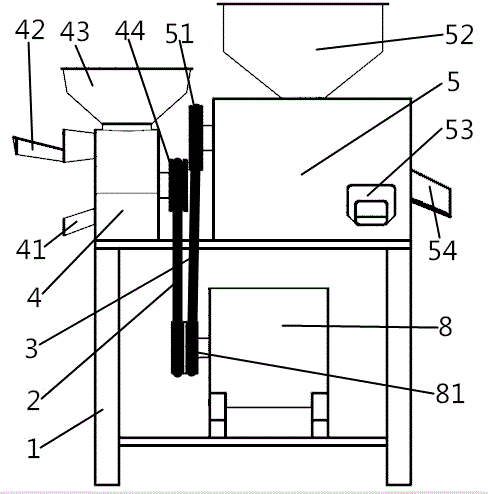

[0019] see figure 1 or figure 2 , the multi-mode rice milling and pulverizing combination machine of the present invention comprises frame 1, rice milling machine 5, pulverizer 4, motor 8, frame 1 comprises two layers of frames, motor 8 is placed in the bottom layer, rice milling machine 5 and the upper layer are placed Grinding machine 4, rice milling machine 5 include feeding inlet 52, rice outlet 54, bran outlet 53, belt pulley I51, and pulverizing machine includes pulverizing feeding inlet I42, pulverizing feeding inlet II43, pulverizing discharging outlet 41, Pulley II44, motor 8 includes pulley III81 and has two pulley grooves corresponding to pulley I51 and pulley II44 respectively. By controlling the installation of the b...

Embodiment 2

[0026] Pipeline 7 uses flexible pipe, and the connection of pipeline 7 and bran outlet 53 adopts pipeline 7 one end to directly be enclosed within on the outlet 53 of bran, and all the other are consistent with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com