Coarse material discharge opening of spin-vibration screen

A discharge port and rotary vibrating screen technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of slow discharge speed, poor sealing performance, and dust leakage of vibrating materials, so as to improve work efficiency and discharge Good speed and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

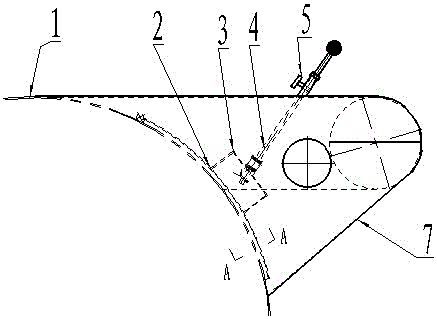

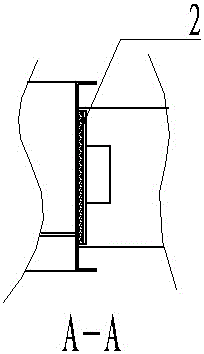

[0008] The embodiment is described in detail in conjunction with the accompanying drawings. The present invention is an improvement to the prior art. It includes a discharge pipe 1 with the outlet at a right angle downward. The hypotenuse 7 that is open to the connecting end of the screen frame is rotated from one side to the other in the open port of the discharge pipe, and an outward-opening gate 3 is installed, and the operating rod 4 of the gate is outward from the discharge pipe through one side. The sealing is drawn out, and the upper end of the operating rod is equipped with a locking device 6 and a fixed screw rod 5 . A sealing rubber layer 2 is provided on the contact surface between the gate and the screen frame. After the above improvements, the inlet of the discharge pipe can be doubled, which can effectively increase the discharge speed and improve the screening efficiency. The gate is opened from the inside to the outside, which can effectively improve the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com