Coupler yoke tail inner bent corner machining rotating clamp

A technology for rotating fixtures and coupler frames, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machine parts, etc., and can solve the problems affecting the processing efficiency, processing accuracy and complex positioning accuracy of the inner bending angle of the tail of the 17-type coupler frame of railway wagons , cumbersome operation and other problems, to achieve the effect of reasonable design, simple operation and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Some preferred embodiments of the present invention are listed below to help further understanding of the present invention, and the scope of protection of the present invention is not limited to these preferred embodiments.

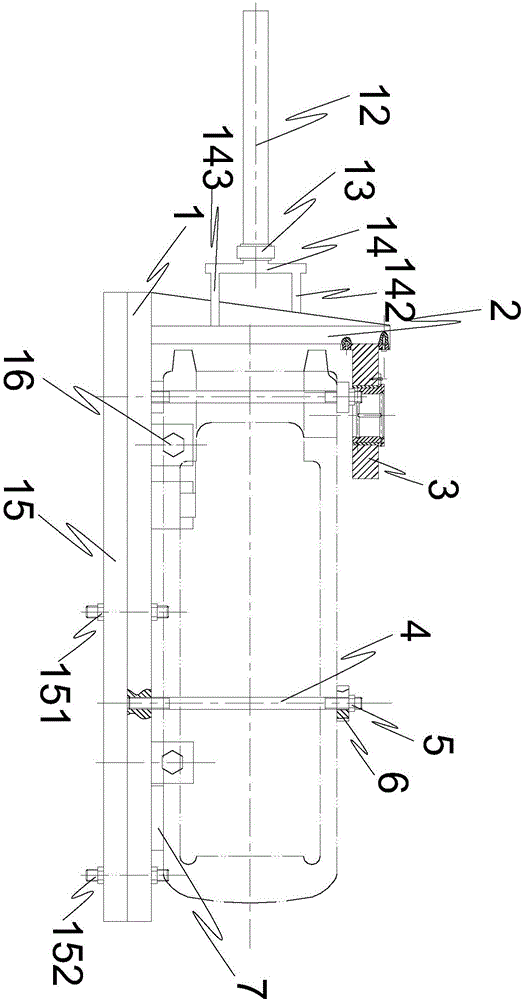

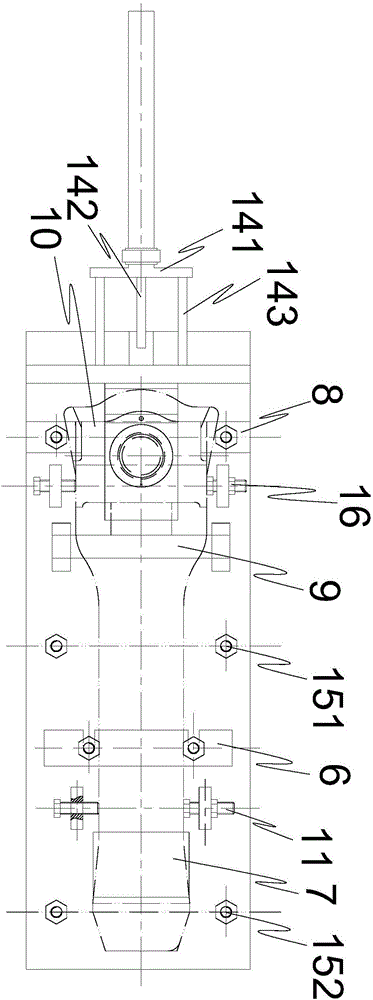

[0024] Such as figure 1 and figure 2 Shown is a rotating fixture for machining the inner corner of the tail of the hook tail frame, which is characterized in that it consists of a rotating bottom plate 1, a fixed vertical plate 2, a boring die 3, a screw rod 4, a hex nut 5, a front pressure plate 6, a front positioning block 7, and a rear Pressing plate 8, positioning rod 9, rear positioning block 10, positioning screw 11, rotating rod 12, rotating shaft 13, rotating bracket 14, fixed base plate 15 and rear positioning screw 16 are composed, and the upper side of the rotating base plate 1 is provided with a fixed vertical plate 2. The fixed vertical plate 2 is connected to the boring die 3 through bolts, the front pressure plate 6 is located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com