Transmission device of tool bit angle-adjustable electric screwdriver

An electric screwdriver and transmission technology, applied in the field of mechanical parts, can solve the problems that the blade cannot fully enter, the screwdriver cannot transmit torque, the screwdriver cannot work, etc., and achieves the effects of strong promotion value, compact structure, and convenient installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

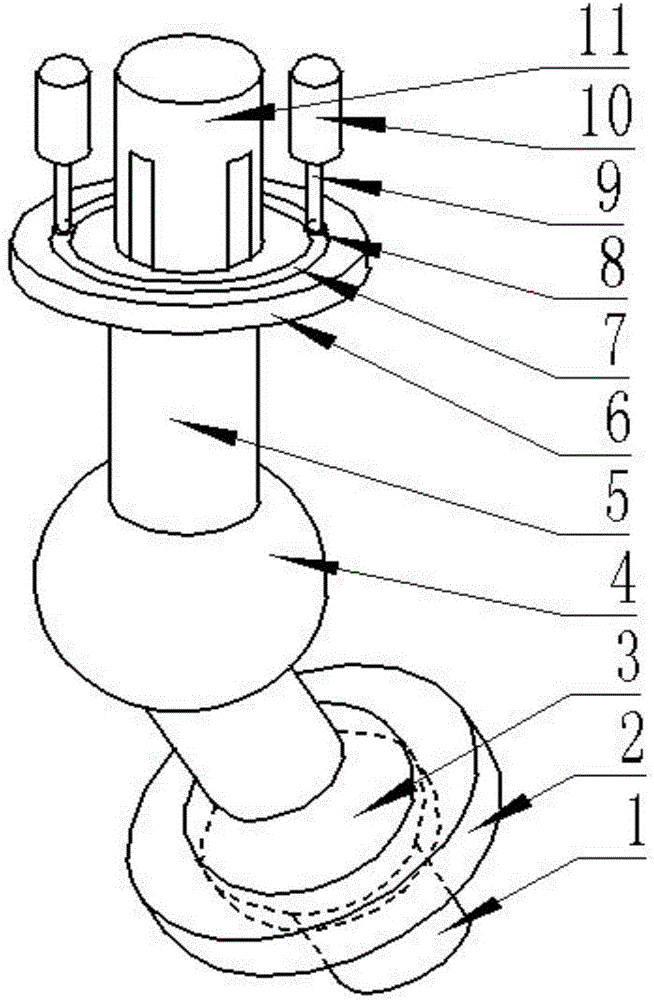

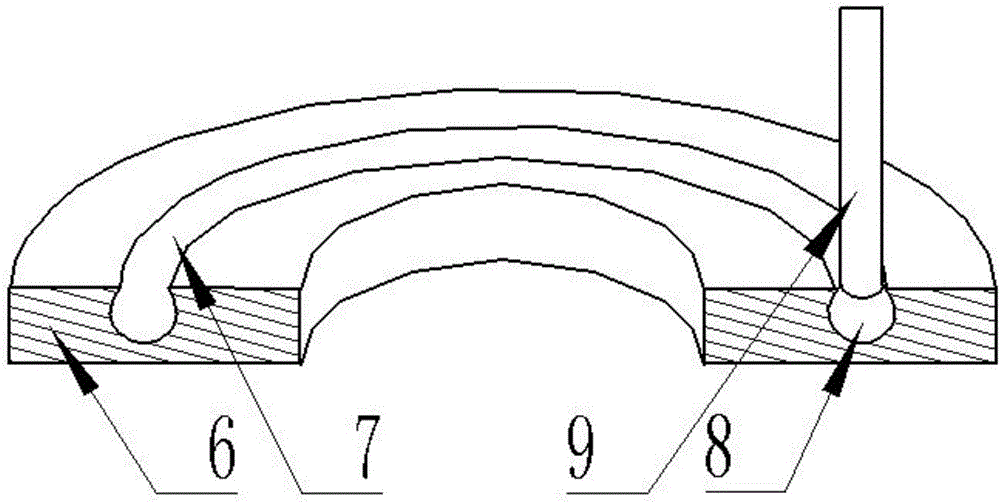

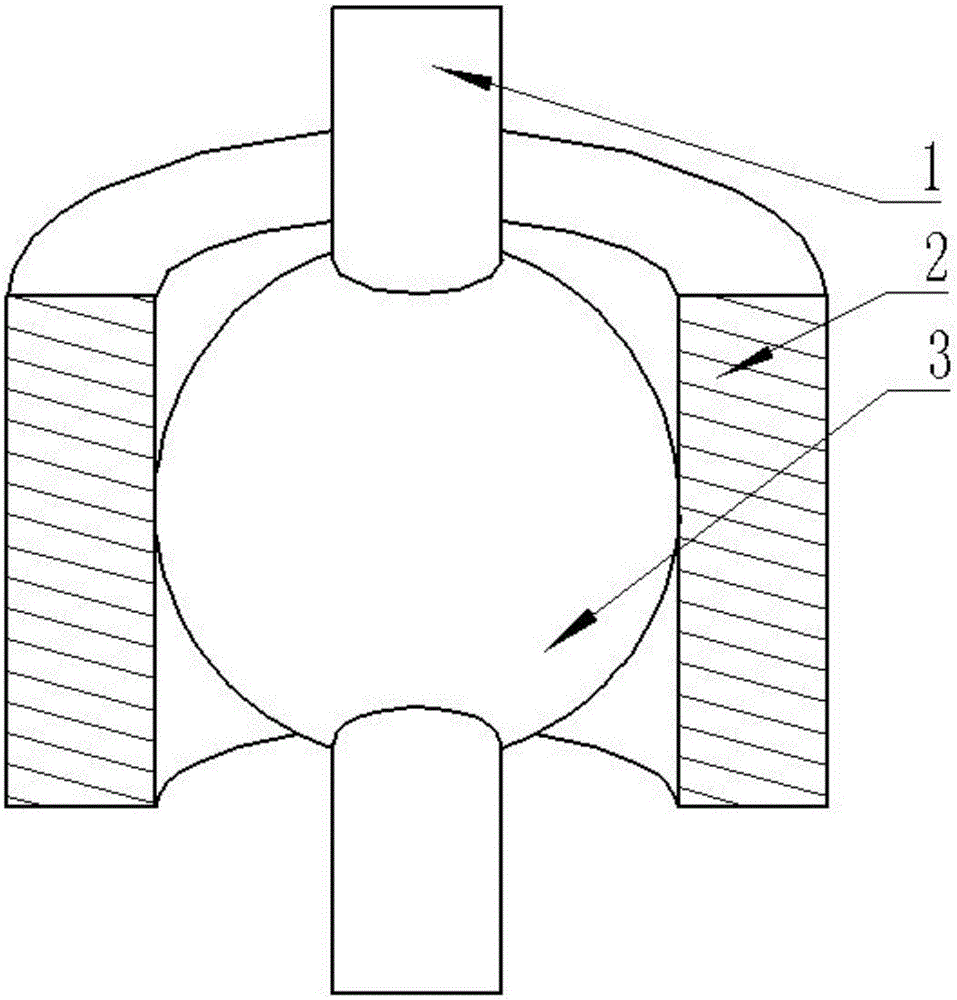

[0028] Such as figure 1 As shown in -5, in order to overcome the defects of the prior art, the present invention provides a transmission device of an electric screwdriver with an adjustable cutter head angle, which includes a ring column 2, a cardan shaft 4, a driven shaft 5 and a driving shaft 11. A sliding groove 14 is provided on the side of the driving shaft 11. The sliding groove 14 is parallel to the axis of the driving shaft 11. The sliding groove 14 penetrates from the middle of the driving shaft 11 to the free end of the driving shaft 11. A sliding plate 12 is installed in the sliding groove 11. The sliding plate 12 is installed on one end of the driven shaft 5, the driven shaft 5 is fixedly equipped with a turntable 6, the driven shaft 5 passes through the middle part of the turntable 6 vertically, the turntable 6 is provided with a round groove 7, and the round groove 7 is equipped with a second Two spheres 8, the second sphere 8 is connected with the piston rod 9, ...

Embodiment 2

[0034] This embodiment is further improved on the basis of embodiment 1, as figure 1 As shown in -5, in order to realize that the driving shaft 11 drives the driven shaft 5 and the rotating shaft 1 to rotate, the angle between the driven shaft 5 and the rotating shaft 1 is variable, and the axis of the driving shaft 11 is collinear with the axis of the driven shaft 5; The axis of the shaft 5 intersects the axis of the rotating shaft 1 .

[0035] The cross-section of the circular groove 7 is an arc, the diameter of which is the same as that of the second sphere 8, the depth of the circular groove 7 is greater than the diameter of the second sphere 8, and the length of the line connecting the two ends of the arc is greater than the diameter of the piston rod 9. This setting enables the piston rod 9 to control the expansion and contraction of the turntable 6, but the piston rod 9 does not affect the rotation of the turntable 6.

[0036] The inner diameter of the ring column 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com