Differential type bearing dismounting device

A bearing removal device, differential technology, applied in hand-held tools, manufacturing tools, etc., can solve the problems of large moving stroke of the central threaded shaft, large size of bearing removal tool, inconvenient to carry, etc., to achieve increased friction and structure Simple, easy-to-remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and example the present invention will be further described:

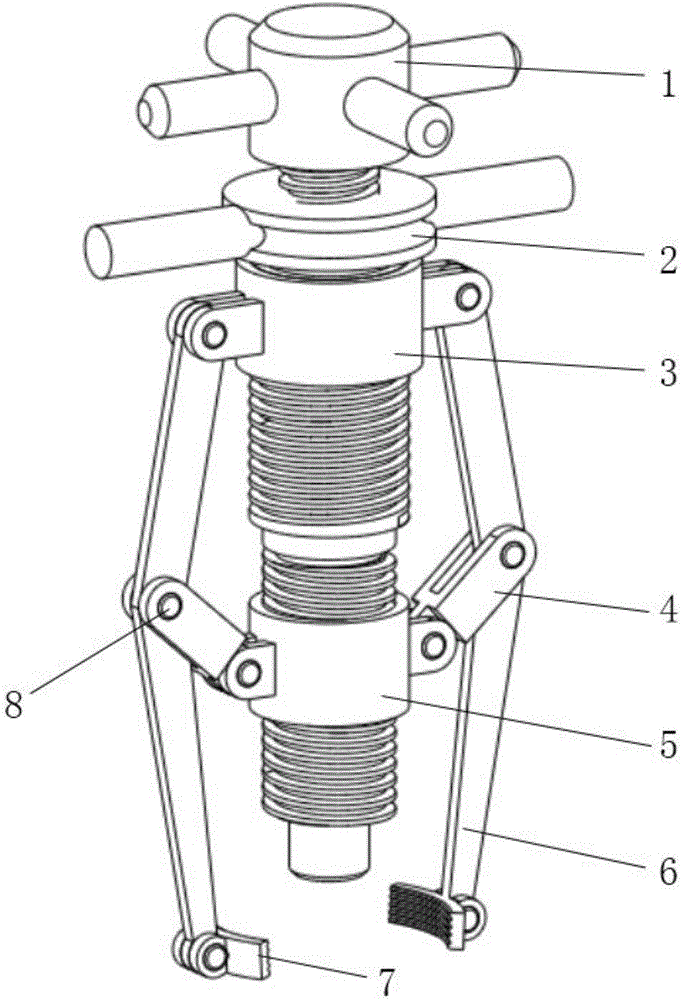

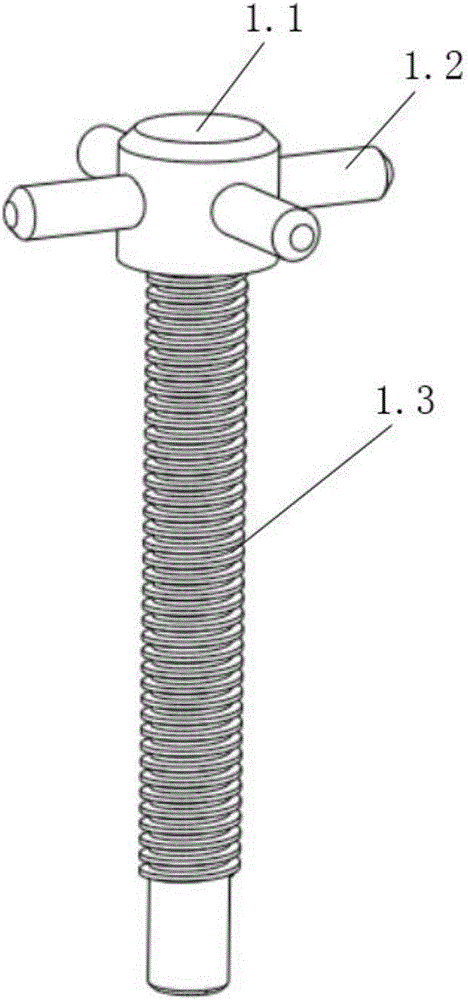

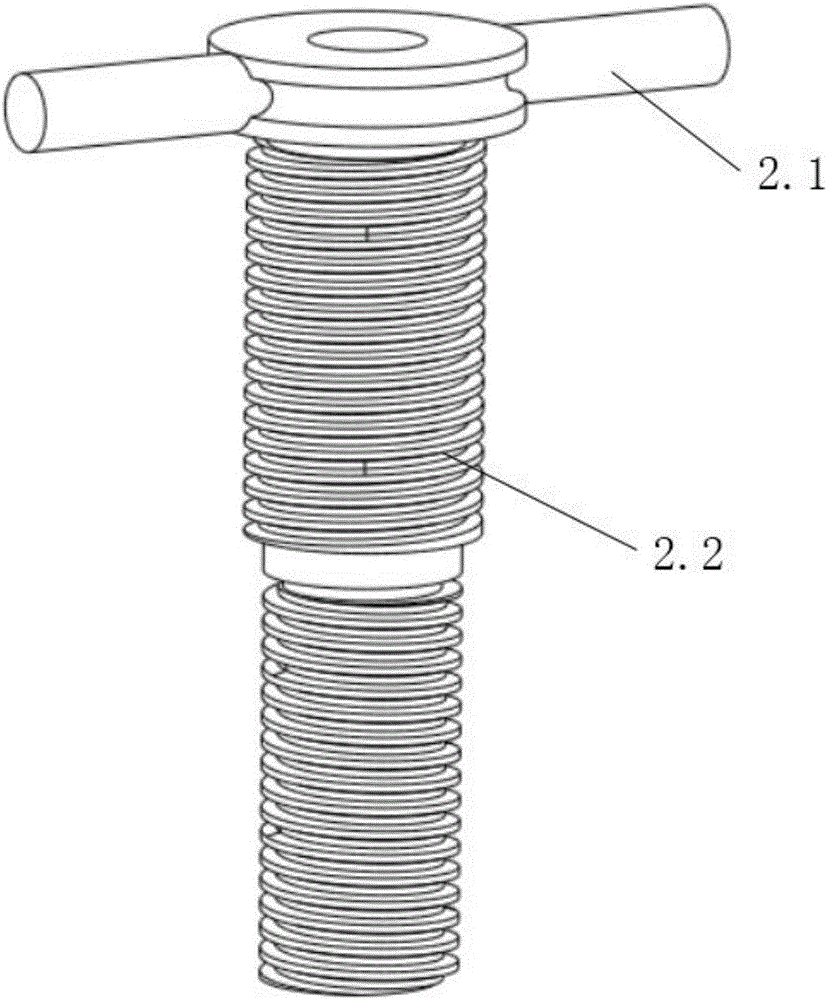

[0023] Such as Figure 1-7 As shown, a differential bearing removal device of the present invention includes a power shaft (1), a preload sleeve (2), an upper differential sleeve (3), a movable joint (4), a lower differential sleeve (5), Connecting plate (6), curved splint (7), pin (8), the power shaft (1) is screwed to the pre-tightening sleeve (2), the upper differential sleeve (3), the lower differential The sleeves (5) are threadedly connected with the pre-tightening sleeves (2), the upper end of the connecting plate (6) is connected with the upper differential sleeve (3) through pins (8), and the middle and the movable joint (4) are connected through pins (8) ), the lower end is connected with the arc splint (7) through a pin (8), one end of the movable section (4) is connected with the lower differential sleeve (5) through a pin (8), and the other end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com