Electric tool cabinet

A technology of power tools and outer frames, applied in the field of power tool cabinets, can solve the problems of lack of convenient functions, poor structural stability, short service life, etc., and achieve the effects of convenient installation, weight reduction, and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

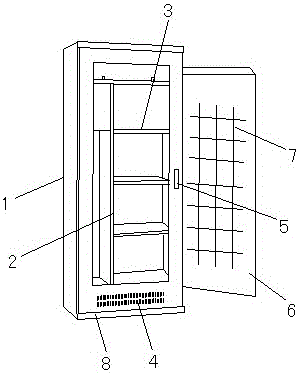

[0023] Such as figure 1 As shown, a power tool cabinet includes an outer frame 1, a baffle 2 and a partition 3, the baffle 2 is arranged in the outer frame 1, the baffle 2 is welded to the outer frame 1, and the baffle 2 is Vertically arranged, the partition 3 is arranged on one side of the baffle 2, the partition 3 is welded with the baffle 2, and more than one partition 3 is provided, and the bottom of the outer frame 1 is provided with a cooling hole 4, so One side of the outer frame 1 is provided with a mounting hole 5 and a door panel 6, the door panel 6 is hinged with the outer frame 1 through the mounting hole 5, and the outer frame 1 is provided with a reinforcing rib 7, and the reinforcing rib 7 is provided with more than one , the reinforcing ribs 7 are arranged in a criss-cross pattern, and the reinforcing ribs 7 are welded to the door panel 6 .

[0024] The distance between the partitions 3 is 50 cm.

[0025] More than one cooling hole 4 is provided.

[0026] A ...

Embodiment 2

[0037] Such as figure 1 As shown, a power tool cabinet includes an outer frame 1, a baffle 2 and a partition 3, the baffle 2 is arranged in the outer frame 1, the baffle 2 is welded to the outer frame 1, and the baffle 2 is Vertically arranged, the partition 3 is arranged on one side of the baffle 2, the partition 3 is welded with the baffle 2, and more than one partition 3 is provided, and the bottom of the outer frame 1 is provided with a cooling hole 4, so One side of the outer frame 1 is provided with a mounting hole 5 and a door panel 6, the door panel 6 is hinged with the outer frame 1 through the mounting hole 5, and the outer frame 1 is provided with a reinforcing rib 7, and the reinforcing rib 7 is provided with more than one , the reinforcing ribs 7 are arranged in a criss-cross pattern, and the reinforcing ribs 7 are welded to the door panel 6 .

[0038] The distance between the partitions 3 is 50 cm.

[0039] More than one cooling hole 4 is provided.

[0040] A ...

Embodiment 3

[0051] Such as figure 1 As shown, a power tool cabinet includes an outer frame 1, a baffle 2 and a partition 3, the baffle 2 is arranged in the outer frame 1, the baffle 2 is welded to the outer frame 1, and the baffle 2 is Vertically arranged, the partition 3 is arranged on one side of the baffle 2, the partition 3 is welded with the baffle 2, and more than one partition 3 is provided, and the bottom of the outer frame 1 is provided with a cooling hole 4, so One side of the outer frame 1 is provided with a mounting hole 5 and a door panel 6, the door panel 6 is hinged with the outer frame 1 through the mounting hole 5, and the outer frame 1 is provided with a reinforcing rib 7, and the reinforcing rib 7 is provided with more than one , the reinforcing ribs 7 are arranged in a criss-cross pattern, and the reinforcing ribs 7 are welded to the door panel 6 .

[0052] The distance between the partitions 3 is 50 cm.

[0053] More than one cooling hole 4 is provided.

[0054] A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com