Anti-pilling gridding fabric

An anti-pilling and mesh technology, which is applied in the field of fabrics and textile fabrics, can solve the problems of easy staining, affecting wearing comfort, and easy embedding of dirt inside the fabric, etc., to achieve the effect of enhancing anti-pilling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

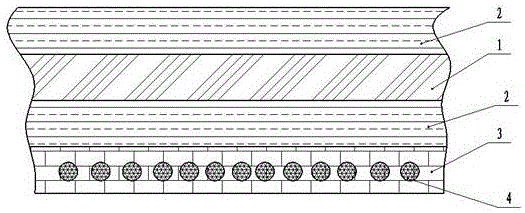

[0018] see figure 1 , an anti-pilling mesh fabric, comprising an easy-to-clean functional layer, a mesh layer is provided on both sides of the easy-to-clean functional layer, and an inner layer is arranged on the inner side of the mesh layer; the inner layer of the inner layer is radially The activated carbon fiber bundles are evenly arranged; the easy-to-clean functional layer and the mesh layer are fixed inside and outside by hot melt adhesive, and the inner layer and the mesh layer are fixed by sewing around; the easy-to-clean functional layer is made of flax fiber and jute It is made of fiber blending; the mesh layer is made of three-dimensional mesh superfine fiber base cloth; the inner layer is made of long-staple cotton fiber.

[0019] A preparation process of mesh fabric, comprising the steps of:

[0020] Step 1: Fabricate each layer, and after fixing, fabric dyeing and antibacterial finishing are in the same bath;

[0021] Step 2: post-soaping treatment; in this ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com