A garbage sorting and removal system

A technology of garbage classification and garbage bins, which is used in garbage cleaning, garbage collection, garbage transmission and other directions to save ground space, protect the living environment, and avoid the spread of diseases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following examples serve to illustrate the invention.

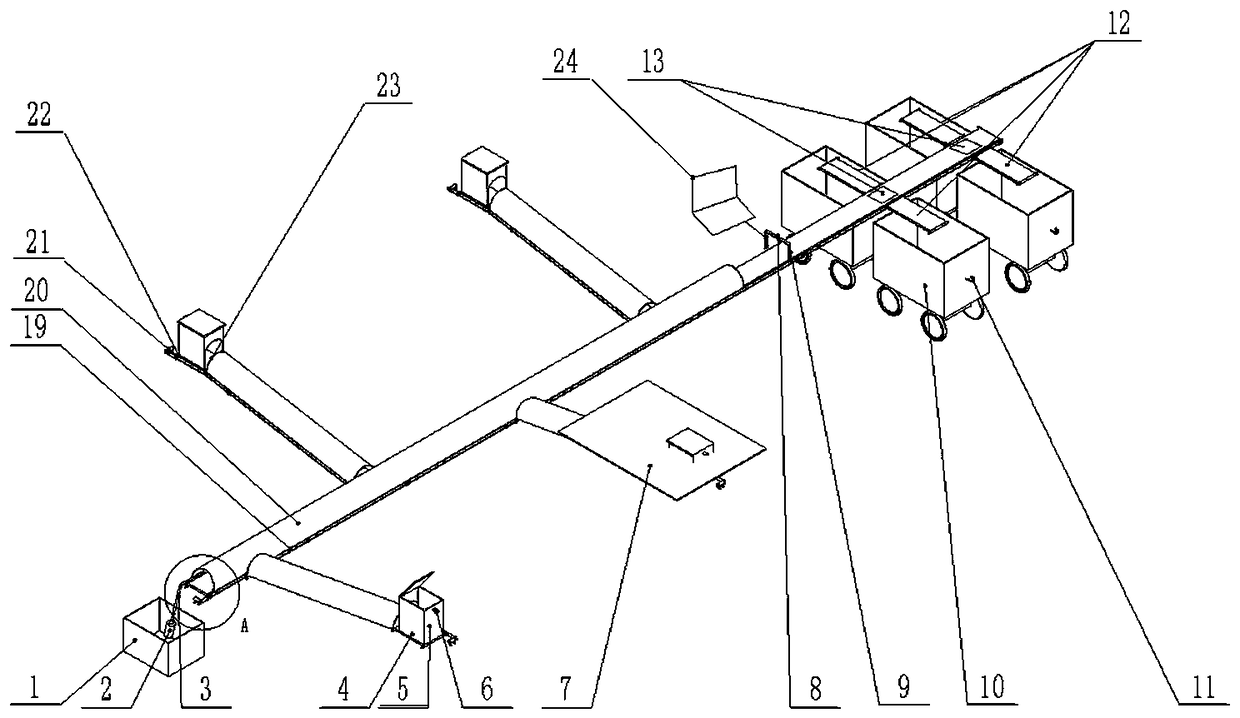

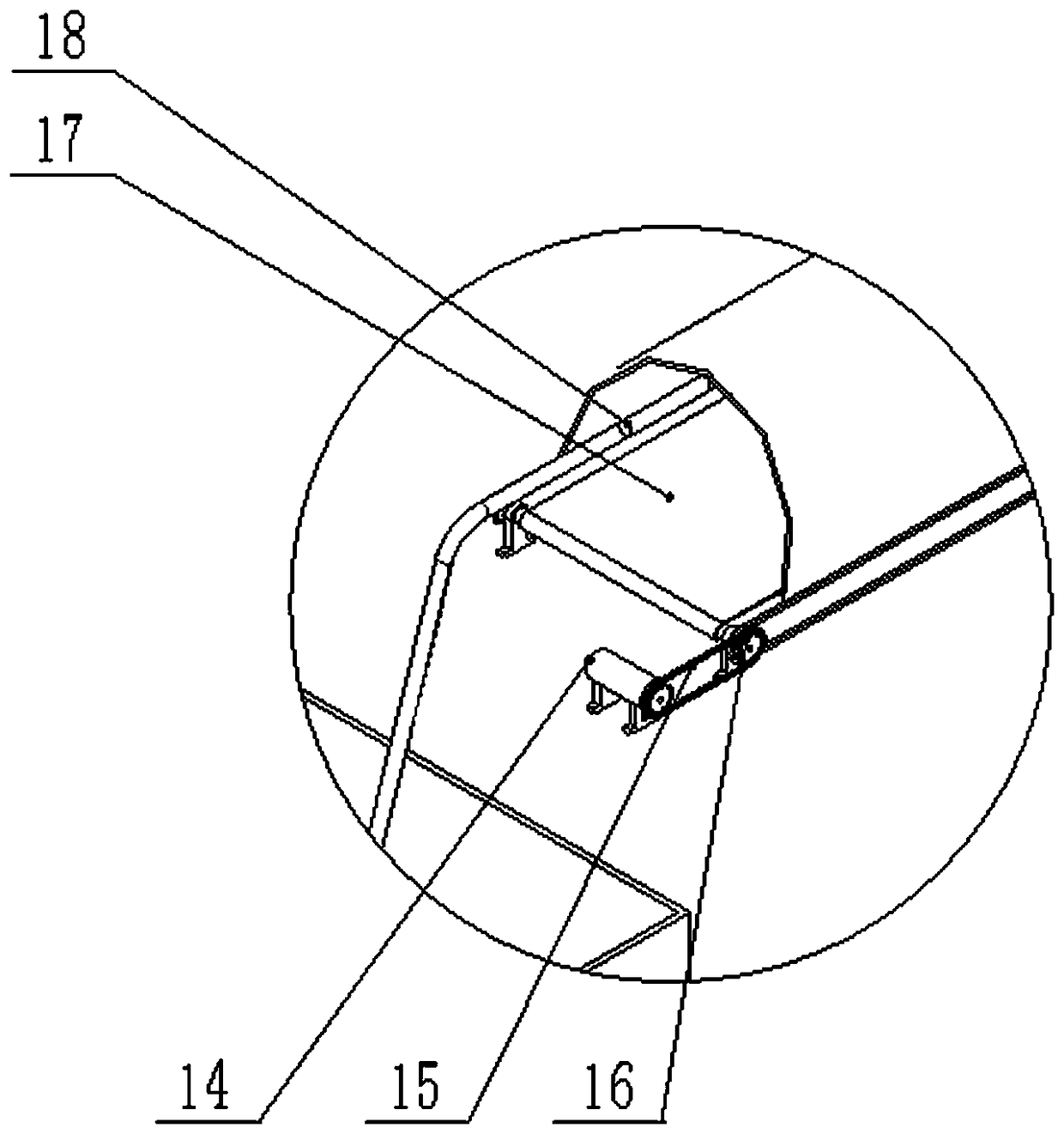

[0014] Such as figure 1 As shown, a garbage sorting and removal system is composed of a garbage bin, a conveying device, a cleaning and disinfecting device, a sorting device and a garbage truck, and these devices are all installed under the ground. Transmission device comprises main transmission device and sub-transmission device, and main transmission device and sub-transmission device are all made up of support 22, motor, chain, sprocket wheel and conveyor belt, and motor drives sprocket wheel to rotate by chain, drives conveyor belt to move. A shield 20 is arranged above the conveyor belt 23, and the shield is installed on the support. Rubbish bin 5 is installed on the support of sub-transmission device, and foot switch 6 and sensor 4 are housed on the dustbin. See figure 2 and figure 1 , one end of the main conveyor belt 17 is provided with a cleaning and disinfection device, including a water tank 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com