Overturning electromagnet and toothed plate gravity overturning mechanism for stacker crane

A technology of turning mechanism and electromagnet, which is applied in the direction of conveyor, object stacking, transportation and packaging, etc. It can solve the problems of low production efficiency, poor packaging quality and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

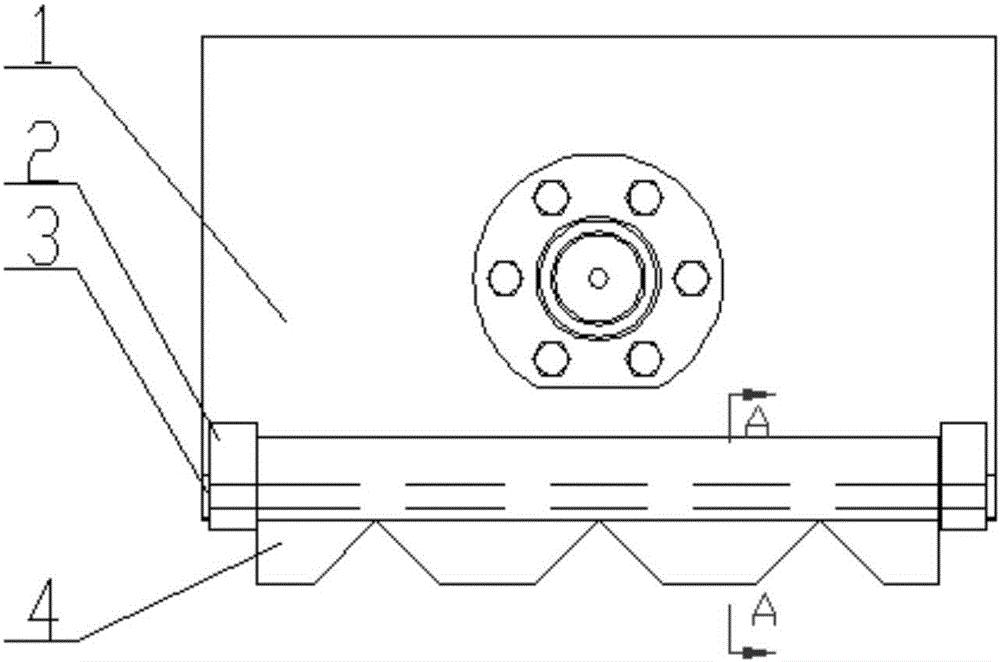

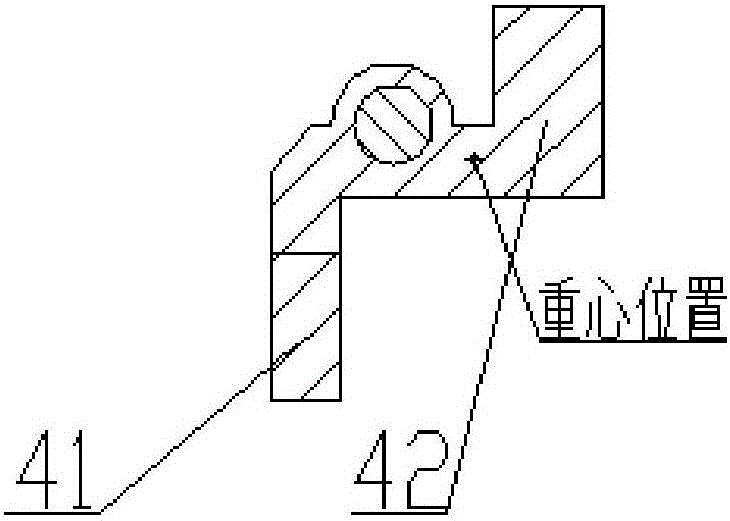

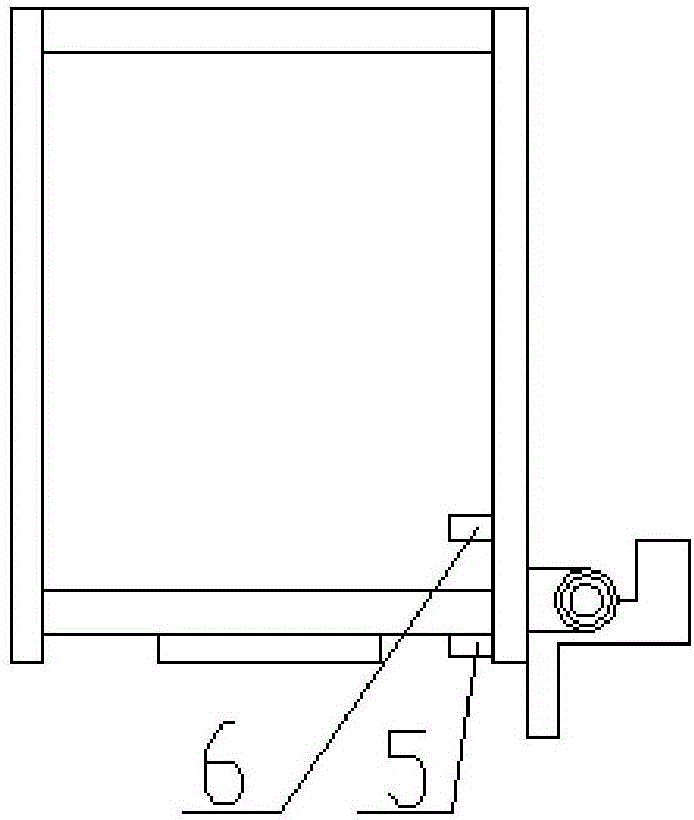

[0023] like figure 1 As shown, the palletizer of the present invention uses an overturning electromagnet gear plate gravity overturning mechanism, including an overturning electromagnet housing 1, and a tooth plate 4 that is overturned and connected with the overturning electromagnet housing 1; the overturning electromagnet housing 4 vertical section steel The side of the movement direction is provided with a support 2, and the support 2 is provided with a turning shaft 3; the tooth plate 4 includes a zigzag tooth plate body 41 hinged with the turning shaft, and the bottom of the zigzag tooth plate body is connected to the The hinged part of the turning shaft is provided with a counterweight plate 42 for turning the sawtooth tooth plate body over.

[0024] like figure 2 As shown in the structural diagram of the toothed plate in the present invention, the toothed plate includes a hinged section hinged with the turning shaft, the left side of the hinged section extends downwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com