Automatic assembling device

An automatic assembly device and rotary connection technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as work-related injuries, operator's hand injuries, and large assembly energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

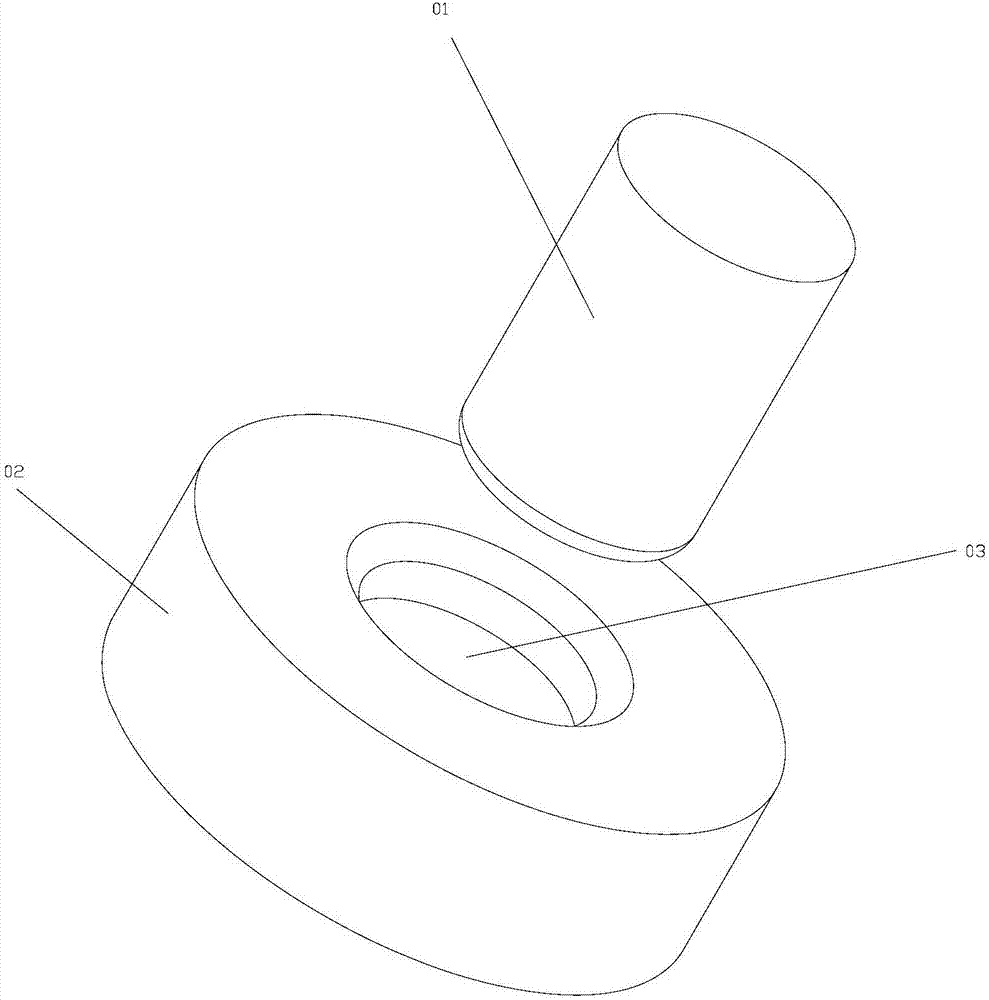

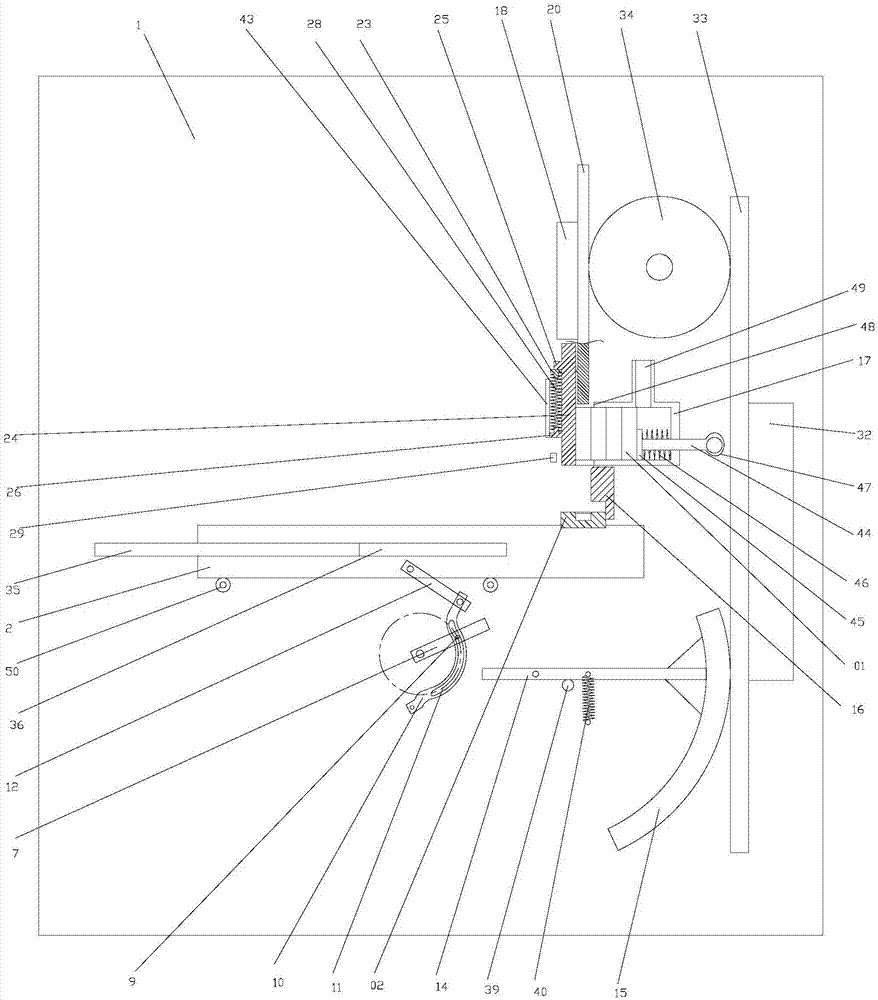

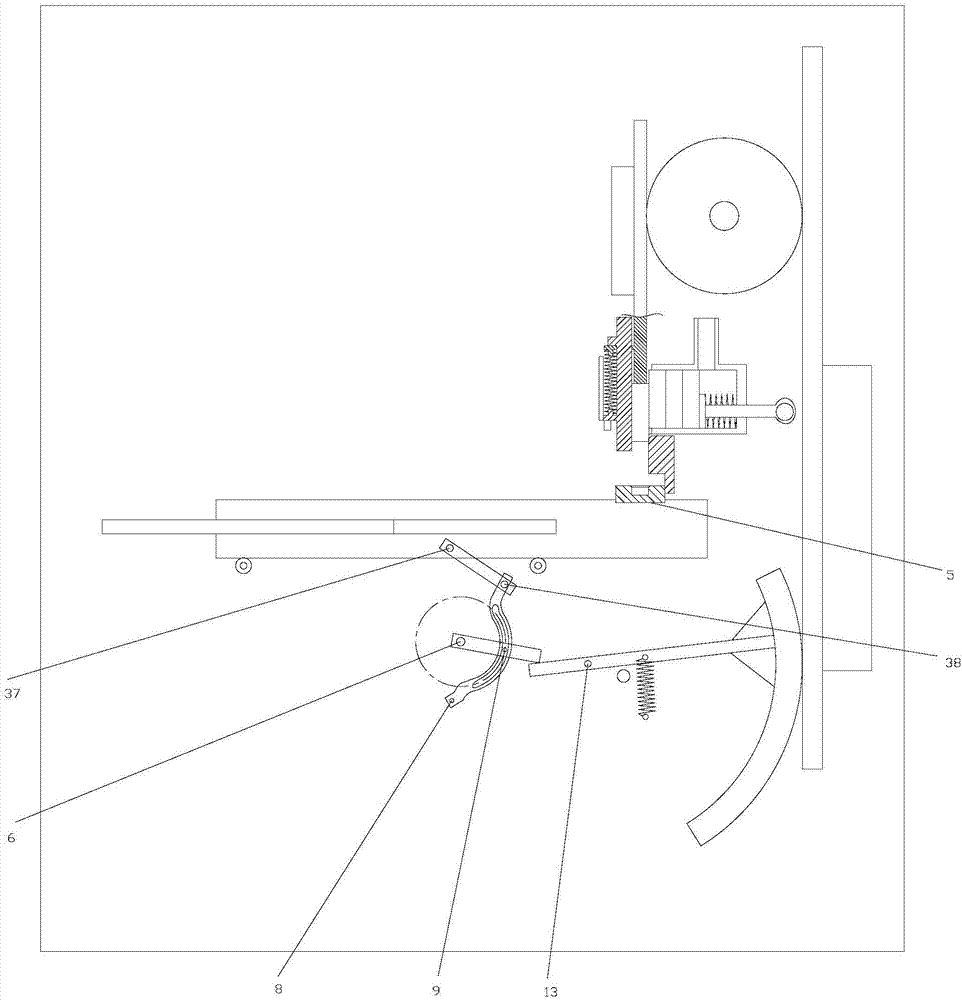

[0030]As shown in the figure, the automatic assembly device of the present invention includes a base 1, on which a slide table 2 for placing the disk 02 is slidably connected, and the slide table 2 is provided with a positioning hole 5 for accommodating the disk 02. The cross-sectional area of the hole 5 is greater than the radial section of the disk 02, so that the disk 02 can be initially positioned in the positioning hole 5, and the inner concave surface of the third arc-shaped baffle 31 on the stopper 16 is pressed against the outer peripheral wall of the disk 02 Just can realize the accurate positioning of disc 2, because the diameter of the third arc-shaped baffle 31 is equal to the diameter of disc 02, the inner concave surface of the third arc-shaped baffle 31 can fit with the outer peripheral wall of disc 02, that is, the third arc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com