Transverse flat glass snapping method

A flat glass, horizontal breaking technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of tracking difficulty and breaking errors, and achieve the effect of simplifying the control process, accurate breaking position, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

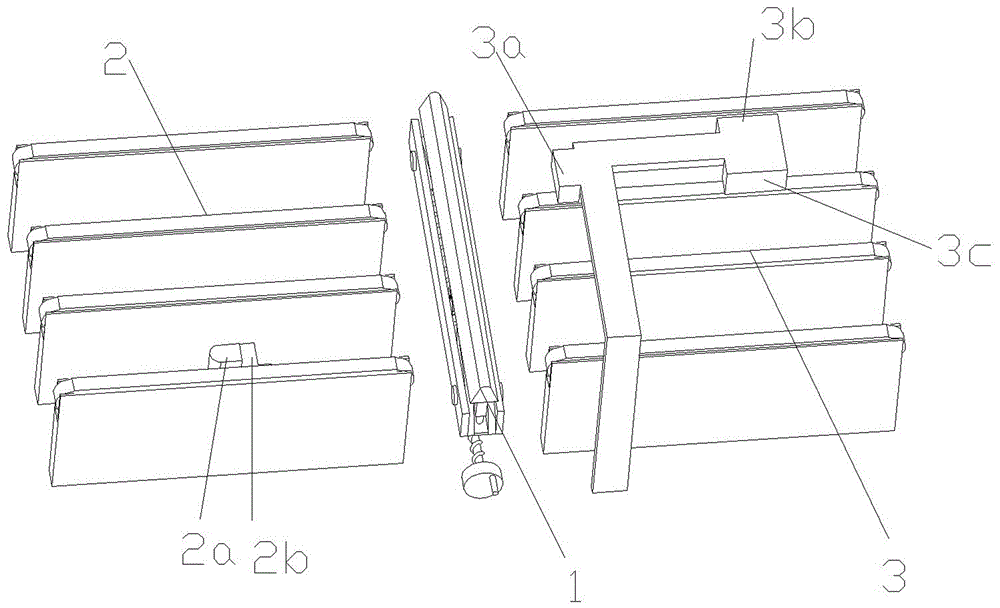

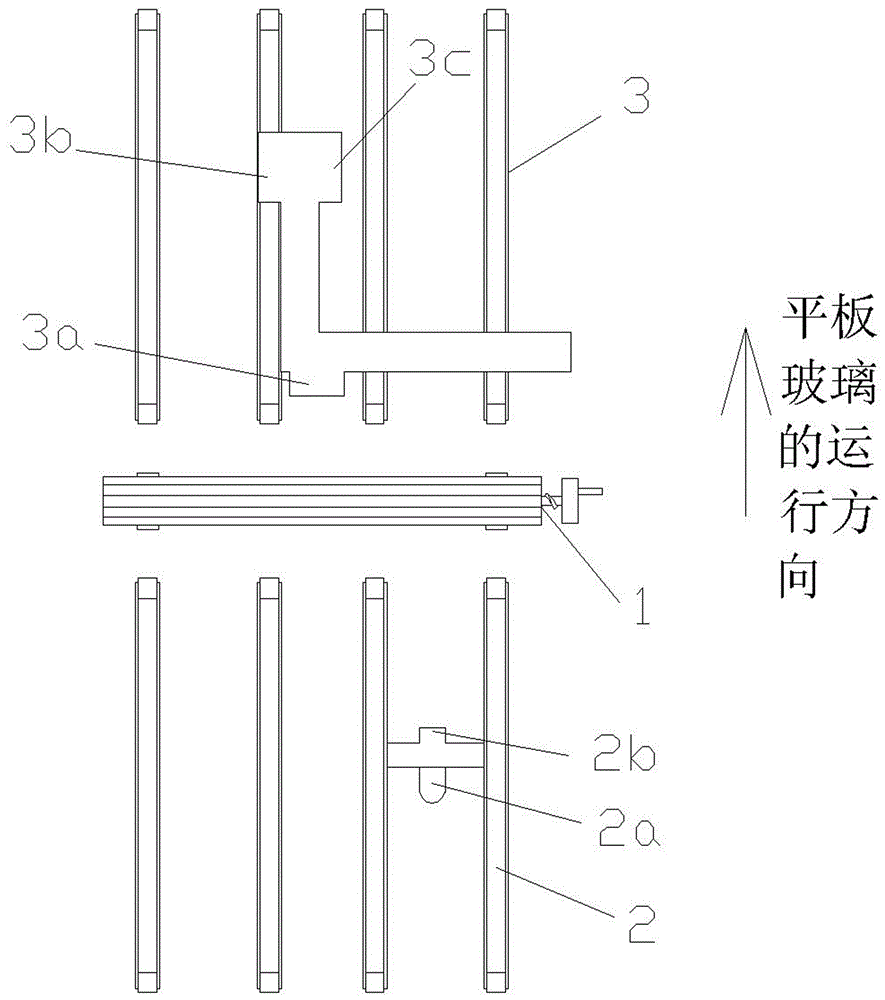

[0015] combine figure 1 and figure 2 As shown, the present invention provides a kind of plate glass transverse breaking method, comprises the following steps:

[0016] a) The first photoelectric switch 2a and encoder 2b are arranged on the front conveying roller table 2 of the horizontal roller 1, and the second photoelectric switch 3a and the third photoelectric switch 3a are arranged in turn on the rear conveying roller table 3 of the horizontal plate roller along the running direction of the plate glass. The photoelectric switch 3b and the fourth photoelectric switch 3c; the positions of the third photoelectric switch 3b and the fourth photoelectric switch 3c along the glass running direction are adjustable;

[0017] b) Start the front conveying roller table 2 and the rear conveying roller table 3 through the PLC, the front conveying roller table 2 will transport the whole piece of flat glass to the rear conveying roller table 3, when the first photoelectric switch 2a det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com