Porous tungsten oxide electrochromic film and preparation method thereof

An electrochromic and tungsten oxide technology, applied in the direction of coating, etc., can solve the problems of affecting the electrochromic performance of the film, the destruction of the porous structure, the complicated process, etc., and achieve the effect of excellent electrochromic performance, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Clean the conductive glass substrate: Clean the ITO conductive glass substrate with an area of 5cm×5cm (square resistance 7-10Ω) with acetone, ethanol, and deionized water for 10 minutes, and dry it at 60°C to obtain a clean ITO conductive glass substrate. glass substrate.

[0036] 2. Configure electrodeposition solution:

[0037] (1) Weigh 4.596g of tungsten powder and put it into a container.

[0038] (2) Measure 14 mL of hydrogen peroxide solution (mass fraction 30%), pour it into a container with tungsten powder for reaction, and react at room temperature, stirring simultaneously during the reaction.

[0039] (3) When the temperature of the solution after the reaction drops to room temperature, a platinum plate is inserted to catalyze, so that the unreacted hydrogen peroxide is partially decomposed. After 12 hours of catalytic reaction, the platinum sheet was taken out to stop the reaction.

[0040] (4) According to the volume ratio V 水 :V 异丙醇 = Mixed solu...

Embodiment 2

[0052] 1. Clean the conductive glass substrate: Clean the ITO conductive glass substrate with an area of 5cm×5cm (square resistance 7-10Ω) with acetone, ethanol, and deionized water for 10 minutes, and dry it at 60°C to obtain a clean ITO conductive glass substrate. glass substrate.

[0053] 2. Configure electrodeposition solution:

[0054] (1) Weigh 4.596g of tungsten powder and put it into a container.

[0055] (2) Measure 18 mL of hydrogen peroxide solution (mass fraction 30%), pour it into a container with tungsten powder, and react at room temperature, stirring simultaneously during the reaction.

[0056] (3) When the temperature of the solution after the reaction drops to room temperature, a platinum plate is inserted to catalyze, so that the unreacted hydrogen peroxide is partially decomposed. After 12 hours of catalytic reaction, the platinum sheet was taken out to stop the reaction.

[0057] (4) According to the volume ratio V 水 :V 异丙醇 = Mixed solution of water...

Embodiment 3

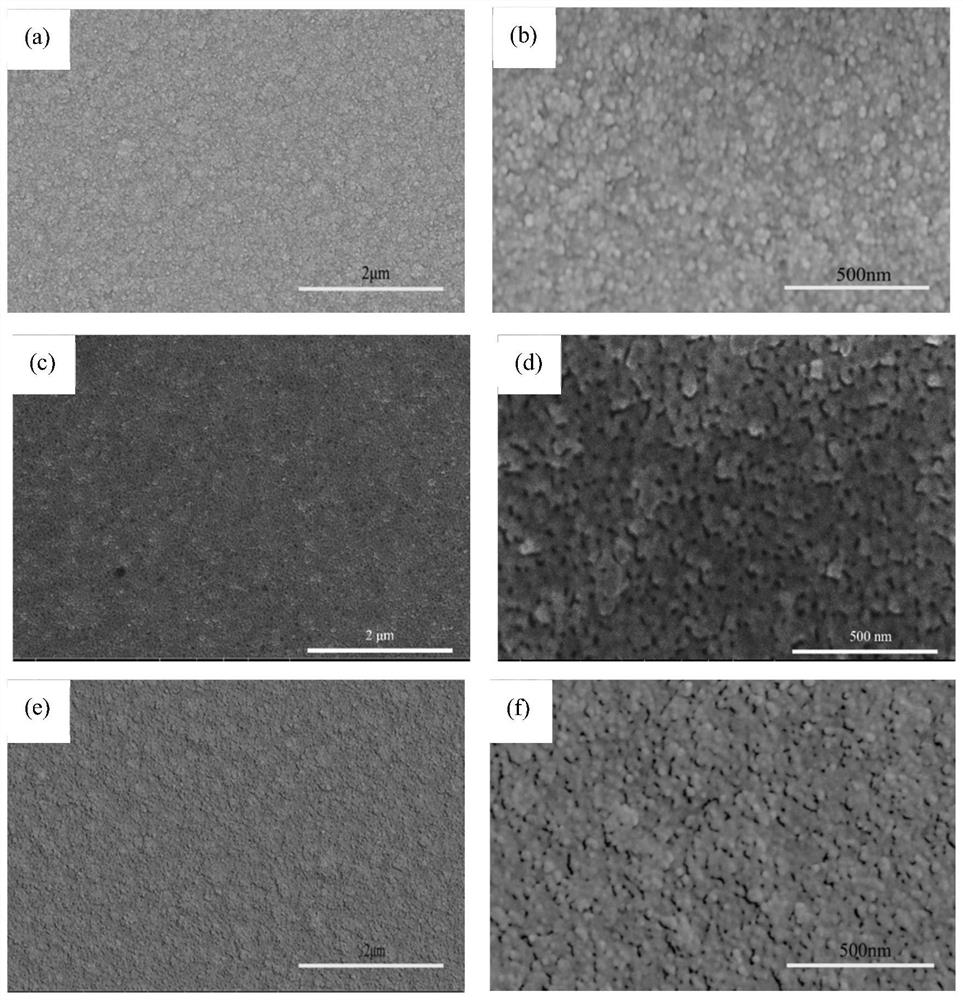

[0073] The surface morphology of the porous tungsten oxide obtained in Example 3 is as follows: figure 1 (e), (f) shown.

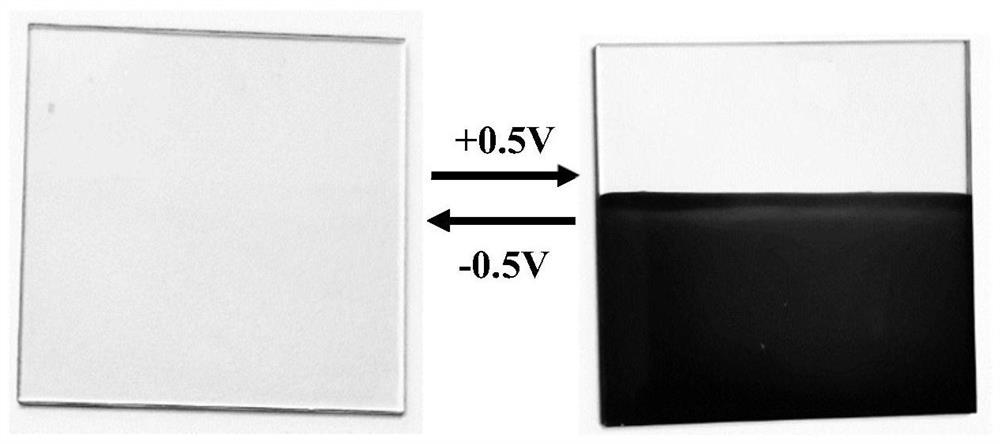

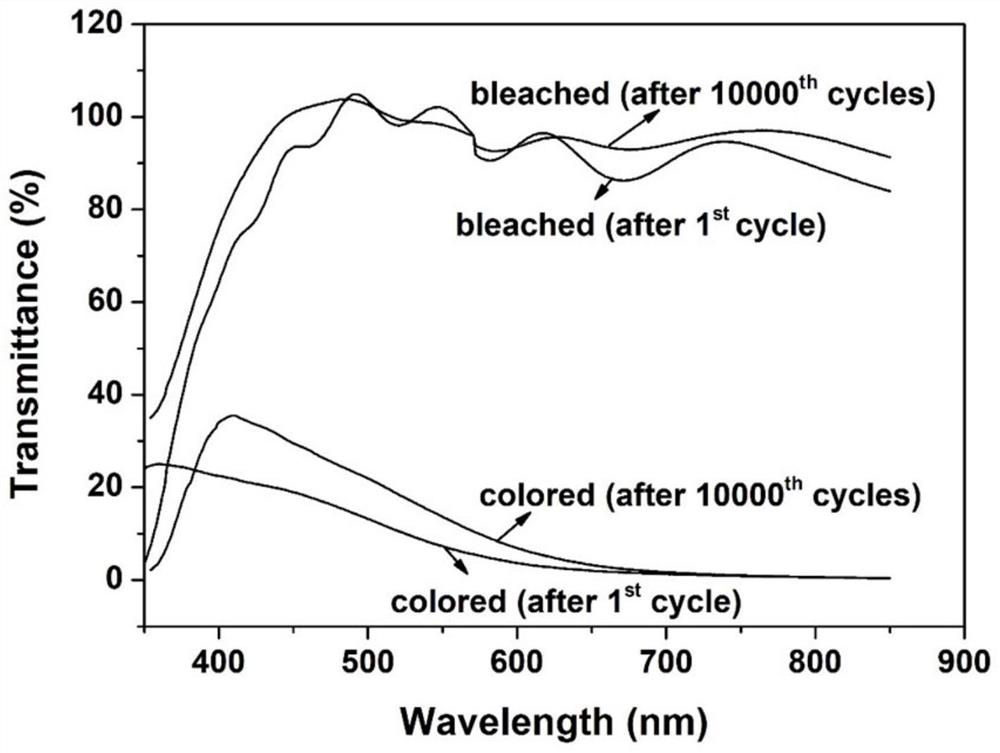

[0074] The electrochromic performance of the porous tungsten oxide film prepared in Example 3 was tested, and the results are shown in Table 1. The transmittance of the film at 633nm in the faded state reaches 98.6%, the transmittance in the color-developed state reaches 16.3%, and the optical control range is >80%. more, the cycle stability is significantly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com